WAYS AND MEANS.

Page 63

If you've noticed an error in this article please click here to report it so we can fix it.

Interesting Contributions from Our Driver and Mechanic Readers.

A Tool for Withdrawing Floating Axles.

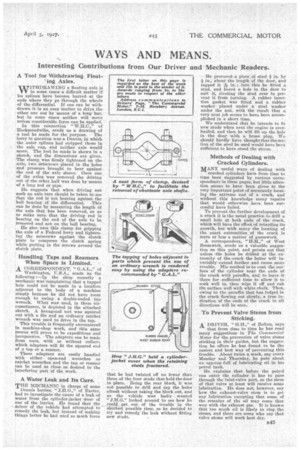

WITHDRAWING a floating axle is in some cases a difficult matter if its splines have become burred at the ends where they go through the wheels of the differential. If one can be withdrawn it is an easy matter to drive the other one out by means of a long bar, but in some cases neither will move unless considerable force can be applied. In this connection " W.H.C.," of Heckmondwike, sends us a drawing of a tool he made for the purpose. The lorry in question was a Dennis, in which the outer splines had stripped those in the axle cap, and neither axle would move. The tool he made is shown in a sketch, and the dimensions are given. The clamp was firmly tightened on the axle, two setscrews placed in the holes and pressure brought to bear against the end of the axle sleeve. Once one of the axles was removed the driving out of the other half was done by means of a long rod or pipe.

He suggests that when driving out such an axle care should be taken to see that the rod is not bearing against the

ball bearing of the differential. This can be done by measuring the length of the axle that has been removed, so as to make sure that the driving rod is bearing on the end of the axle to be removed. and not on the ball bearing.

. Be also uses this clamp for gripping the axle of a Federal lorry and tightening the setscrews against the clutch plate to compress the clutch spring while putting in the screws around the clutchplate.

Handling Taps and Reamers When Space is Limited.

A CORRESPONDENT, " G.A.L.," of Washington, U-S.A., sends us the following :—In the shop recently a mechanic was'complaining that a tapped hole could not be made in a location adjacent. to the body of a machine simply because he did not have room enough to swing a double-ended tap wrench. What was used, in these circumstances, is depicted in the attached sketch. A hexagonal nut was squared out with a file and an ordinary ratchet wrench was used to drive in the tap.

This trouble is frequently encountered in machine-shop work, and this same means will_ prove to he expeditious and inexpensive. The adapters can be made from nuts, with or without collars, which adapters will fit the squared end of a tap or a reamer.

These adapters are easily handled with either open-end ' wrenches or ratchet wrenches and the tap or reamer can be used as close as desired to the Interfering part of the work.

A Water Leak and Its Cure.

THE MECHANIC in charge of some Dennis lorries, " J.H.O.," of Exeter, had to investigate the cause of a leak of water from the cylinder-jacket door of one of the lorries. He found that the driver of the vehicle had attempted to remedy the leak, hut instead of making things better he had used so much force that he had twisted off no fewer than three of the four studs that hold the door in place. Being the rear block, it was not passible to drill and tap the holes afresh without taking the block out, and as the vehicle was badly wanted " j.H.G." looked around to see how he could, get out of the trouble in the shortest possible time, so he decided to try and remedy the leak without fitting new studs.

He procured a piece of steel / in. by / in., about the length of the door, and tapped it /56in.; into this he fitted a stud, and bored a hole in the door to suit it, riveting the stud over to prevent it from turning. A rubber insertion gasket was fitted and a rubber washer placed under a steel washer under the nut, with the result that a very peat job seems to have been accomplished in a short time.

We understand that he intends to fit new studs when next the engine is overhauled, and then he will fill up the hole in the door with a brass plug. We should hardly have thought that the section of the steel he used would have been sufficient to have stood the stress.

Methods of Dealing with Cracked Cylinders.

M..9.NY useful ways of dealing with cracked cylinders have from time to

time been suggested by various cormspondents in these pages, but little atten

tion seems to have been given to the very important point of accurately locating the extreme end of a crack, and without this knowledge many repairs that would otherwise have been successful have failed.

To prevent the further development of a crack it is the usual practice to drill a small hole at both ends of the crack, • which will have the effect of retarding its growth, but with many the locating of the exact extremities, of the crack is more or less a matter of guesswork. A correspondent, " HNI.," of West l3romwich, sends us a valuable suggestion on this point, and points out that unless the holes be drilled at the extremity of the 'crack the latter will invariably extend farther and cause more trouble. His method is to coat the surface of the cylinder near the ends of • the crack with paraffin, and to leave it there for ,sufficient time to allow it to soak well in, then wipe it off and rub tire surface well with white chalk. Then, owing to the paraffin that has lodged in the crack flowing out slowly, a true indication of the ends of the crack in all directions will be seen.

• To Prevent Valve Stems from Sticking.

A DRIVER, "11.11.," of Bolton, says that from time to time he has read many suggestions in The Commercial Motor for the prevention of valve stems sticking in their guides, but the suggestion he offers he has found to be the easiest and best way of preventing this trouble. About twice a week, say every Monday and Thursday, he puts about an egg-cup full of lubricating oil in his petrol tank. He explains that before the petrol can enter the cylinder it has to pass through the inlet-valve port, so the stem of that valve at least will receive some lubrication. He does not, however, say how the exhaust-valve stem is to get any lubrication excepting that some of the remains of the oil may come that way with the exhaust gas. It is known that too much oil is likely to clog the stems, and there are some who say that valve stems will work best dry.