Practical Features in New Tyre Retreading Process

Page 41

If you've noticed an error in this article please click here to report it so we can fix it.

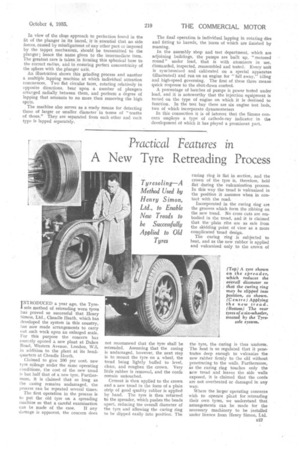

I NTRODUCED a year ago, the Tyre sole method of retreading worn tyres has proved so successful that Henry Simon, Ltd., Cheadle Heath, which has developed the system in this country, has now made arrangements to carry out such work upon an enlarged scale. For this purpose the concern has recently opened a new plant at Dukes Road, Western Avenue, London, W.3, in addition to the plant at its headquarters at Cheadle Heath.

Claimed to give 100 per cent. new tyre mileage under the same operating conditions, the cost of the new tread is but half that of a new tyre, Furthermore, it is claimed that so long as the casing remains undamaged, the process can be repeated several times.

The first operation in the process is to put the old tyre on a spreading machine so that a careful examination can be made of the case. If any damage is apparent, the concern does not recommend that the tyre shall be retreaded. Assuming that the casing is undamaged, however, the next step is to mount the tyre on a wheel, the tread being lightly buffed to level, clean, and roughen the crown. Very little rubber is removed, and the cords remain untouched.

Cement is then applied to the crown and a new tread in the form of a plain strip of good quality rubber is applied by hand. The tyre is then returned to the spreader, which pushes the beads apart, reducing the overall diameter of the tyre and allowing the curing ring to be slipped easily into position. The curing ring is flat in section, and the crown of the tyre is, therefore, held flat during the vulcanization process. In this way the tread is yuleanized in the position it assumes when in contact with the road.

Incorporated in the curing ring are the grooves which form the ribbing on the new tread. No cross cuts are embodied in the tread, and it is claimed that the -plain ribs are as safe from the skidding point of view as a more complicated tread design.

The curing ring is subjected to heat, and as the new, rubber is applied and vulcanized only to the crown of

the tyre, the curing is thus uniform. The heat is so regulated that it penetrates deep enough to vulcanize the new rubber firmly to the old without penetrating to the walls. Furthermore, as the curing ring touches only the mew tread and leaves the side walls exposed, it is claimed that the cords are not overheated or damaged in any way.

Where the larger operating concerns wish to operate plant for retreading their own tyres, we understand that arrangements can be made for the necessary machinery to be installed under licence from Henry Simon, Ltd.