MAKING BEST USE OF THE FORD,

Page 53

If you've noticed an error in this article please click here to report it so we can fix it.

Valuable Advice on Every Phase of Ford Transport which will Appeal to the Owner, Driver and Repairer.

547.—Locating a Crankcase • 'Crack.

4 leak recently developed in the Crankcase of an old Ford. and as it was a very small one it was found extremely difficult to locate. ' However, by adopting, the foil-Owing procedure thia

successfully effeeted :—

The crankcase was cleaned thoroughly inside and out and the bottom rubbed-over with some thin white lead, which was then wiped off and the engine turned by hand a few times. • Upon examining the crankcase it was found that the position of the craek was indicated by a line of ivhite lead along it. In this instance the 'crack proved' to' be unimportant and Wasrepaired by the

use of an iron cement. • A procedure soniewhat similar to this can sometimes be claployed in_the case of cracks in erankshafts. If the shaft be thoroughly cleaned and then struck sharply at varioas points with a wooden mallet, oil contained in minute cracks will be forced to the surface and will at once indicate the potition of the cracks.

548.—Fitting the Sleeves of Rear Axle Bearings.

As the outer roller, bearing sleeves of the rear axle are made right and left, it is important that they should be fitted to the correct sides of the axle, as, unless care be exercised, a right sleeve may be fitted at the left side and vice versa. It should be noted that the greaser hole is above the slot when the locking point is towards the outer endof the axle. If care be taken in this there is no risk of fitting the sleeves in the wrong positions.

549.—Grinding-in the Valves.

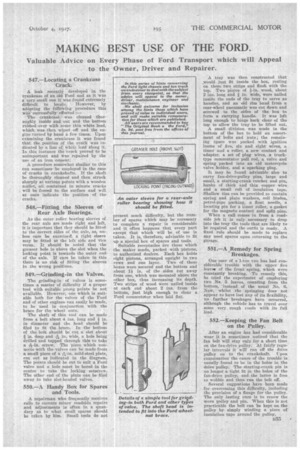

The grinding-in of valves is sometimes a matter of difficulty if a proper tool with suitable Prong points be not available. However, one which is suitable both for the valves of the Ford and of other engines can easily be made, to be used in conjunction with the brace for the wheel ants.

The shaft of this tool can be made from a bolt about 4 ins, long and in diameter and the head should be filed to fit the brace. In the' bottom of the bolt should be cut a slot about'

4. in. deep and in, wide, a hole being drilled and tapped through this to take -j4in. screw. The piece which connects with the valves can he made from a small piece of a mild-steel plate, cut out as indicated in the diagram: The points should he cut to suit a Font valve and a hole must be bored• in the centre to take the locking setscrew: The other end of the plate can be hied away to take slot-headed valves.

550.—A Handy Box for Sparesand Tools.

A. repairman who frequently receives, calls to execute minor roadside repairs and adjustments is often in a quandary as to what small spares should be taken by him. Small tools do not present .much difficulty, but the number of spares which may be necessary to complete a repair is considerable and it often happens that every part except that which will be of use is taken. It is, therefore, advisable to fit up a special box of spares and tools.

Suitable receptacles are those which the maker sends, packed with pistons, to authorized dealers. Each box holds eight pistons, arranged upright in two rows and one layer. Two of these boxes were secured and the bottom and about 11in. of the sides cut away from one, which was mounted above the other box, thus increasing its depth. Two strips of wood were nailed inside at each end about 2 ins, from the bottom, just high enough to clear a Ford commutErtor when laid flat.

A tray was then constructed that would just fit inside the box, resting on these two strips and flush with the top. Two pieces of I-in. wood, about 2 ins, long and i• in. wide, were nailed inside the ends of the tray to serve as handles, and an old rim band from a rear-wheel pneumatic was cut down and screwed to the sides of the box to form a carrying handle. It was left long enough to hinge back clear of the top to allow the tray to be lifted out.

A small division was made in the buttom of the box to hold an assortment of bolts and nuts; the remaining space was packed with ignition looms of five, six and eight wires, a timer nail a roller, a new contact and adapter, a set 'of plug wires, a trucktype commutator pull rod, a valve and spring packed into an old motorcycle valve. holder, and a sparking plug.

It may be found advisable also to carry fan-drive-pulley pins, large and small, a starting-crank ratchet and pin, banks of thick and thin copper wire and a small roll of insulation tape. Shallow tins can he provided to contain spring and plain washers, coil blades, petrol-pipe packing, a float needle, a locating pin for a timer roller, a gasket for the magneto contact and split pins.

When a call comes in from a roadside job it is only necessary to drop into the tray the tools that are likely to be required and the outfit is ready. A fixed rule should be made to replace any used spares upon returning to the garage.

551.—A .Remedy for Spring Breakages.

One user of a 1-ton van has had considerable trouble with the upper five leavn of the front spring, -Which were constantly breaking. To remedy this, he tried the experime.nt of employing two Na. 5 leaves, counting from the bottom, instead of the usual No. ti. Nod', whilst the springing does not appear to have lost any of its flexibility, nofurther breakages have occurred, although the vehicle has to travel over some very rough roads with its full load, 552.—Keeping the Fan Belt on the Pulley.

• After an engine has had considerable wear it is sometimes noticed that the fan belt will stay only for a short time on the fan-drive pulley. At faitly'regu-• lar intervals it' will run off the drive Pulley on to • the crankshaft. Upon examination' the cause of the trouble is usually found to be in the holds in the drive pulley. The starting-crank pin is no longer. a tight fit in the holes of the fan-drive pulley, amid, the latter is free to wobble and thus run the belt off.

. Several suggestions have been made for overcoming this difficulty, including the provision of a flange for the pulley. The only lasting cure is to renew the worn pulley and pin. When this is not practicable the belt can be kept on the pulley by simply winding a piece of insulation tape around the palley.