Needle-bearing Universal Joints

Page 41

If you've noticed an error in this article please click here to report it so we can fix it.

nNE of the best-known types of all

metal universal joint on the British market is that made by Hardy, Spicer and Co., Ltd., of Birmingham. This company has now brought out a new joint of the needle-bearing pattern, a brief reference to which was made several months ago by us.

There is no denying that the wear (and consequent upkeep) on plainbearing joints is a prominent feature of maintenance work, particularly when lubrication has been neglected, whilst enforced limitations of dimensions has necessarily resulted in considerable bearing pressures.

The new type of joint utilizes needleroller bearings in place of plain bushes. These bearings use particularly small uncaged rollers, so that a great many can be accommodated in a bearing of small diameter, They are not untried, as a considerable number has been on test for over 12 months on many makes of vehicle operating under a variety of conditions.

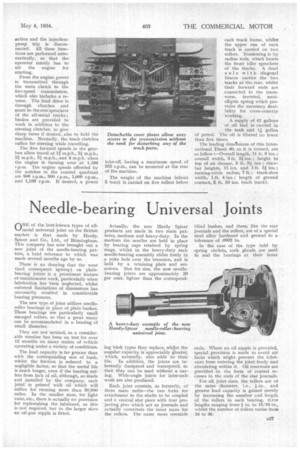

The load capacity is far greater than with the corresponding size of bush, whilst the friction is reduced to a negligible factor, so that the useful life is much longer, even if the bearing suffers from lack of oil, although, as made and installed by the company, each joint is primed with oil which will suffice for running more than 50,000 miles. In the smaller sizes, for light vans, etc., there is actually no provision for replenishing the lubricant, as this is not required, but in the larger sizes an oil-gun nipple is fitted. Actually, the new Hardy Spicer products are made in two main patterns, medium and heavy-duty. In the medium the needles are held in place by bearing caps retained by spring rings, whilst in the heavy-duty each needle-bearing assembly slides freely in a yoke hole over the trunnion, and is held by a retaining plate and setscrews. Size for size, the new needlebearing joints are approximately 20 per cent, lighter than the correspond

ing ',fish types they replace, whilst the angular capacity is appreciably greater, which, naturally, also adds to their

life In addition, the joints are inherently dustproof and waterproof, so that they can be used without a casing. Wide-angle joints for inter-axle work are also produced.

Each joint consists, as formerly, of three main units—the two forks for attachment to the shafts to be coupled and a central star piece with four projecling pins which act as journals and actually constitute the inner races for the rollers. The outer races resemble blind bushes, and these, like the star journals and the rollers, are of a special steel alloy hardened and ground to a tolerance of .0002 in.

In the case of the type held by spring circlets, cork glands are used to seal the bearings at their inner

ends. Where an oil nipple is provided, special provision, is made to avoid airlocks which might prevent the lubricant from entering the joint freely and circulating within it. Oil reservoirs are provided in the. form of central recesses in the ends of the star journals.

For all joint sizes, the rollers are of the same diameter, i.e., lain., and greater load capacity is gained merely by increasing the number and length of the rollers in each bearing, these lengths ranging from .1 in. to 15/16 in., whilst the number of rollers varies from 16 to 36.