Price as tested: £90,000 (ex-VAT). Includes truck, trailer and all

Page 32

Page 33

Page 34

Page 36

Page 37

If you've noticed an error in this article please click here to report it so we can fix it.

commercially available equipment seen here. Does not include Eminox catalyst or synthetic lubricants.

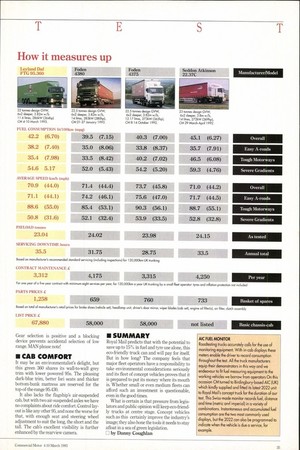

Engine: 11.6 litres, 268kW (359hp). Tested GCW: 38.00 tonnes. Payload: 20.68 tonnes. Speed: 70.9km/h (44.0mph).

Fuel consumption: 42.11it/100km (6.7mpg).

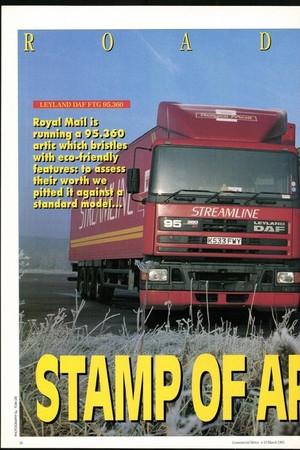

This week we are departing from our usual practice to bring you a roadtest within a roadtest. Since August Royal Mail has been working with Leyland Daf and a number of component suppliers on a six-axle "green" artic. The FTG 95.360 tractor and its Cartwright box trailer join five experimental Leyland Daf vans and 17-tonners in Royal Mail's environmental trials: the first two concept vehicles (near-identical Leyland Daf 60-Series 17-tonners) were unveiled at the Birmingham Motor Show in September 1990. Some features of the new artic are already in use on the rigids, including aerodynamic bodywork and air brake silencers.

The trials were designed to test the environmental and cost claims made for a range of products, and assess their potential for Royal Mail's 30,000 vehicles. Any benefits will be worthwhile in a fleet which clocks up a staggering 2,500,000km a day.

CM usually tests tractors using one of two purpose-built Crane Fruehauf semi-trailers. This time we used the 13.6m, tri-axle Cartwright EFT 36 dry freight van which is on trial with the 95 Series unit.

The artic was unveiled at the IRTE show early last year, complete with eco-friendly green livery, and was featured in these pages soon after (CM16-22 July 1992). Since joining the Royal Mail fleet it has been kept busy delivering letters as part of the Streamline service for palletised bulk mail. We took the vehicle round our standard three-day Scottish route in the cold, calm days just before Christmas.

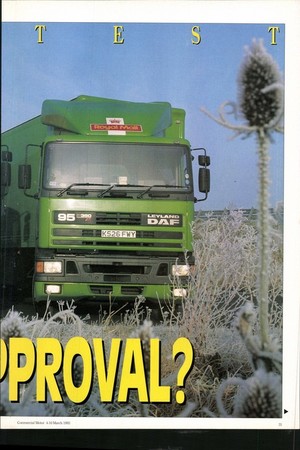

The green 95.360 is one of a batch of 75 Daf tractors; the rest are standard models and we ran one of them (finished in Royal Mail's familiar red livery) alongside it to serve as a yardstick.

Apart from finding out whether the green machine offers operational savings as well as environmental benefits, this was our longawaited chance to test a standard 95.360. • PROFILE: THE TRUCK The tractor is an FTG 95360 sleeper-cab model—like other fleet operators Royal Mail specifies sleeper-cabs for their higher residuals. The basic air-suspended chassis features the optional Austrian-certified noise suppression kit including full engine encapsulation and air brake silencing. It all helps reduce drive-by noise levels to 80dB(A).

The engine is Daf 's tied and trusted ATi WS268 11.6-litre straight six developing 268kW (359hp) at 2,200rpm, and 1,500Nm (1,1061bft) of torque at 1,300rpm. It drives the familiar ZF 16-speed Ecosplit gearbox through a single dry plate clutch. Power goes to 295/80 R22.5 tyres mounted on 10-stud steel rims.

The standard 3.82m-wheelbase chassis came with ECAS electronically controlled rear air suspension on the drive and positively steered second axle. An air-dump on the latter, operated by a dashboard button, transfers weight to the drive axle for added traction. The system can be activated at any speed below 241un/h and will re-inflate after five minutes or when the truck reaches 32km/h. The drive axle also features a diff-lock.

The cab is the standard 95 Series singlebunk sleeper. A fixed fifth-wheel coupling was specified to save weight—this is only practical with tri-axle tractors where the trailer fleet is built to known dimensions.

The tractor's other unusual feature was the addition of a single "umbilical cord"mounted from a hinged coupling hung from the front of the fifth wheel. It is an assembly of the three air lines and electrical suzies which eliminates the problems of dirt and tangling associated with conventional coiled hoses. This system also avoids the danger of stretching the connectors when long-pin trailers are used.

The standard exhaust box was replaced with an experimental combined catalytic converter and soot trap made by Eminox and Emissionsteknik of Sweden. The single trap cleans itself every 60 minutes of running time by injecting a small amount of diesel fuel taken from the main tank.

The dery ignites to burn the soot and the resulting pollutants are caught in a second trap where the process is repeated. Between them the trap and catalyst reduce levels of carbon monoxide, hydrocarbons and particulates by more than 80 % .0ther equipment includes a LOGIQ communications system and optional air management kit.

• PROFILE: THE TRAILER The full-length (13.6m) Cartwright triaxle trailer has its kingpin set at the maximum 1.6m. The body features Polyfont GRP laminated plywood panels and rounded corners which is standard throughout the fleet. Additional GRP-faced side skirts and tailored body trim developed by Ricardo further smooth the airflow.

The trailer runs on Rubery Owen-Rockwell Indair air suspension with a rear lift capability and automatic ride height with manual raise and lower. SAF's axle-weight indication system measures suspension pressure: pressure guages are arranged behind a flap on the left side and graduated in tonnes. The same system is fitted to the tractor's drive axle.

Each Pirelli tyre is fitted with the company's Tyrewatch radio-based warning system which warns the driver of any 10% pressure drop via an in-cab display.

Stability is under test with a Hope anti-jacknife device attached to the kingpin; safety while reversing is enhanced with a Sens-NStop retractable rear underrun bar. Category One ABS is fitted on every axle, and spray suppression equipment has been fitted to the entire underside of the trailer.

An aid to reversing safety comes in the form of a Back-Eye rearview camera system with in-cab display from Brigade Electronics. Trucklite rear light clusters, now available from the US, are also on test on the trailer's rear end.

At 8.86 tonnes the Cartwright design has been kept as light as possible while staying within Royal Mail's spec for durability For the Streamline service palletised loads are forklifted aboard so 300mm cross-member centres have been retained below a Transdeck laminated softwood floor.

Softwood is being tested as an alternative to hardwood. It's light, but when we reported the vehicle's debut last July we asked "will it last?" Six months on, the answer is no. The softwood fibres are breaking apart: possibly under the screwing action of forklift truck tyres, Royal Mail's engineers believe. A steel plate covers a hole which recently appeared six feet from the tailboard.

We discovered a potential cause of this type of damage when we were loading the trailer. The forks, while being carried low to the floor as the empty lift truck exited the trailer backwards, scraped the laminated surface when the rear wheel ran up onto the loading ramp. The effects of ordinary wear and tear were also obvious toward the rear of the trailer.

Consumables haven't been neglected in this eco-friendly package either: synthetic oils and bio-degradable greases are used in the automatic chassis lubrication systems of both truck and trailer. • PRODUCTIVITY It all sounds most impressive, so we were surprised to find that despite all its aerodynamic aids the green truck was 5.1% less fuel efficient than the standard 95.360. The reason? We're still checking, but the Eminox cat seems to be the culprit; by raising exhaust back pressure it makes the engine work harder.

Over the three-day/1,180km (733-mile) route, the green and red trucks returned 4221it/100km (6.70mpg) and 40.01it/100km (7.06mpg) respectively. It is impossible to judge the net effect of the green truck's aerodynamic bodywork, but we hope to assess that at a later date.

Payload for the six-axle green artic was a reasonable 20.68 tonnes. Coupled to CM'S tandem-axle curtainsider the 95.360 managed only 23.04 tonnes: Daf twin-steers have always been on the tubby side, so we weren't too surprised.

ION THE ROAD No other combination is as stable as a six-axle artic. This fully air suspended artic was superbly stable under all road conditions. Six axles also offer road fund licence and weight distribution advantages which some operators, especially fridge hauliers, find attractive. On the other hand there are substantial disadvantages in terms of payload, fuel consumption, capital costs, tyre costs and maintenance.

Twinsteers tend to corner well at speed, and so it proved during this test. That is offset by an inability to manoeuvre tightly on that long wheelbase. Couple it to a 13.6 m tri-axle trailer and the driver needs to keep his wits about him when reversing.

Braking felt controlled and secure, which isn't surprising with 12 wheels to spread the work. Category One ABS all round wasn't about to let us get into trouble either, and in the absence of any emergency manoeuvres we have nothing untoward to report.

All those emission-control systems haven't exactly helped fuel economy, but the 360 doesn't seem to have suffered in the power stakes; performance is well up to par.

Driving both trucks confirms our view that Daf 's installation of the Ecosplit is one of the best around.

The single-H pattern with lifting collar for range-changing is leagues ahead of the double-H pattern which is found in some rivals. Gear selection is positive and a blocking device prevents accidental selection of low range. MAN please note!

• CAB COMFORT It may be an environmentalist's delight, but this green 360 shares its wall-to-wall grey trim with lower powered 95s. The pleasing dark-blue trim, better Isri seats and thicker bottom-bunk mattress are reserved for the top-of-the-range 95.430.

It also lacks the flagship's air-suspended cab, but with two air-suspended axles we have no complaints about ride comfort. Control layout is like any other 95, and none the worse for that, with enough seat and steering wheel adjustment to suit the long, the short and the tall. The cab's excellent visibility is further enhanced by the rearview camera. • SUMMARY Royal Mail predicts that with the potential to save up to 15% in fuel and tyre use alone, this eco-friendly truck can and will pay for itself. But in how long? The company feels that major fleet operators have a responsibility to take environmental considerations seriously and its fleet of concept vehicles proves that it is prepared to put its money where its mouth is. Whether small or even medium fleets can afford such an investment is questionable, even in the good times.

What is certain is that pressure from legislators and public opinion will keep eco-friendly trucks at centre stage. Concept vehicles such as this certainly improve the industry's image; they also hone the tools it needs to stay afloat in a sea of green legislation.

El by Danny Coughlan AIC FUEL MONITOR Roadtesting trucks accurately calls for the use of monitoring equipment. With in-cab displays these meters enable the driver to record consumption throughout the test. All the truck manufacturers equip their demonstrators in this way and we endeavour to fit fuel measuring equipment to the working vehicles we borrow from operators On this occasion CM turned to Birdingbury-based AIC (UK) which kindly supplied and fitted its latest 2022 unit to Royal Mail's concept truck for the duration of our test. This Swiss-made monitor records fuel, distance and time (metric and imperial) in a variety of combinations. Instantaneous and accumulated fuel consumption are the two most commonly used displays, but the 2022 can also be programmed to indicate when the vehicle is due a service, for example.