Tar Spraying at Constant Temperature

Page 51

If you've noticed an error in this article please click here to report it so we can fix it.

r-IN many occasions it is ‘../desirable that tar should be transported direct from distillery to site, and delivered almost immediately on to the roadway. This subject has been carefully investigated, and the necessity of keeping the temperature of the tar high enough for efficient application has received special attention.

The methods adopted by Messrs. South Western Tar Distilleries, of Totton, Hants, have been particularly successful.

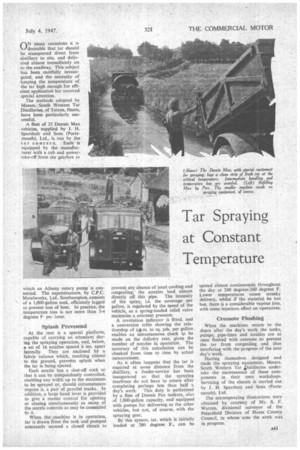

A fleet of 25 Dennis Max vehicles, supplied by J. H. Sparshatt and Sons (Portsmouth), Ltd„ is run by the tar concern. Each is equipped by the manufacturer with a cab and powertake-off from the gearbox to

which an Albany rotary pump-is connected. The superstructure, by C.P.C. Metalworks, Ltd., Southampton, consists of a 1,000-gallon tank, efficiently lagged to prevent loss of heat. In practice, the temperature loss is not more than 3-4 degrees F per hour.

Splash Prevented • At the rear is a special platform, capable of carrying an attendant during the spraying operation, and, below, a set of 16 nozzles spaced •6 ins, apart laterally. They are enclosed by a fabric valance which, reaching almost to the ground, prevents splash when the tar is being ejected.

Each nozzle has a shut-off cock so that it can be independently controlled, enabling any width up to the maximum to be sprayed or, should circumstances require it, a pair of parallel tracks. In addition, a large hand lever is provided to give a master control for opening or closing simultaneously as many of the nozzle controls as may be connected to it.

When the naachine is in operation, tar is drawn from the tank and pumped constantly around a closed circuit to prevent any chance of local cooling and congealing; the nozzles lead almost directly off this pipe. The intensity of the spray, i.e. the coverage per gallon, is regulated by the speed of the vehicle, as a spring-loaded relief valve maintains a constant pressure.

A revolution indicator is fitted, and a conversion table showing the relationship of r.p.m. to sq. yds, per gallon enables an instantaneous check to be made on the delivery rate, given the number of nozzles in operation. The accuracy of this calculation can be checked from time to time by actual measurement.

As it often happens that the tar is required at some distance from the distillery, a feeder-service has been inaugurated so that the spraying machines do not have to return after completing perhaps less than half a day's work. This duty is performed by a fleet of Dennis Pax tankers, also of 1,000-gallon capacity, and equipped with pumps for delivering to the other vehicles, but not, of course, with the spraying gear.

By this system, tar, which is initially loaded at 280 degrees F., can be

spread almost continuously throughout the day at 240 degrees-260 degrees F. Lower temperatures -cause streaky delivery, whilst if the material be too hot, there is a considerable vapour loss, with some injurious effect on operatives.

Creosote Flushing

When the machines return to the depot after the day's work the tanks, pumps, pipe-lines and nozzles are at once flushed with creosote to prevent the tar from congealing and thus interfering, with the progress of the next day's work.

Having themselves designed and made the spraying equipment, Messrs. South Western Tar pistilleries undertake the maintenance of these components in their own workshops. Servicing of the chassis is carried out by J. H. Sparshatt and Sons (Portsmouth), Ltd.

The accompanying illustrations were obtained by courtesy of Mr. S.. F. Warren, divisional surveyor of the Petersfield Division of Hants County Council, in whose area the work was in progress.