How to Keep Your Lorry Fit. XIV.

Page 4

Page 5

Page 6

If you've noticed an error in this article please click here to report it so we can fix it.

This Week We Deal with the Overhead-valve Maudslay War Department Chassis.

The Maudslay War Department chassis is 'unique in all-British commercial-vehicle construction in respect of its engine design, in that overhead valves are used instead of the more conventional type. There are other distinctiv-e features also about this vehicle, not the least important being its spring torque rods.

There is nothing unusual about the methods of lubricating the Mandslay. Commencing with the engine, this is automatically oiled by a force pump which draws supplies from a sump in the base chamber. Fresh lubricant is poured into the crankcase through hinged lids on the crankcase doors on the exhaust side of the engine. When about to refill, the level tap should be opened,. and as soon as oil commences to flow, through it, the driver may be sure that sufficient has been supplied. With this attention, the lubrication of the engine is complete so far as the driver need concern himself, if we except the magneto, which needs a few spots of oil very occasionally.

Behind the engine case is the inverted cone clutch. On the spigot of this will be found a couple of greasers which must have regular attention. The gearbox is filled through a hand hole in the top ; oil should be poured in until it just touches the underside of the shafts. With regard to the rear axle, a combined filler and level indicator is provided. Clean both gearbox and axle case out periodically and put in. fresh oil. This cleaning operation is necessary once every three months.

The chassis being constructed to War Office subvention certificate, both front and rear wheels run on floating phosphor-bronze bushes. These are lubricated by .means of greasers screwed into the wheel hubs, and also from the hub caps which are made to carry oil. A small plug is provided in each cap so that it can be filled.

It is a good precaution. to wipe each lubricator or grease cup before replenishing, as otherwise there is' a risk of dirt or grit entering with the oil or grease. Cleanliness, as a matter of fact, is of extreme importance if any machine is to run satisfactorily. The general appearance of the mechanismis usually a ,clear indication of the amount of attention which it 'receives. Excessive lubrication is _almost as bad as under-lubrication, and should be 'avoided. The crankcase base should be cleaned out and fresh oil put in once every three months.

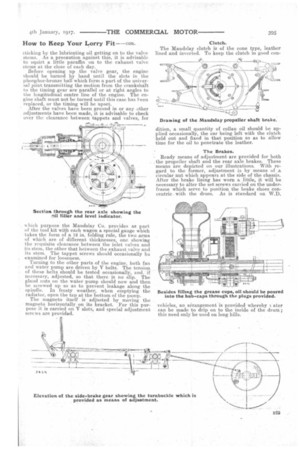

The Valve Gear. .

As already stated, the 'valve gear of the Maudslay engine is of the overhead type. The advantages that may be claimed are increased heat efficiency and also greater accessibility in respect ef the interior workine• parts of the engine, ta.t1 ch as the pistons, connecting rods, etc., which, in this unit, can be removed without taking down the engine or even dismantling the lower half of the craukcaee. On the other hand, the exhaust valves require special attention, particularly if the machine is new. They are, however, readily accessible ; the whole of the valve gear can be exposed after unfastening the hinged bolts of the camshaft casing on the exhaust side, and the exhaust valves complete with the springs and boxes can then be removed. With the valve, and seat taken entirely from the engine, grinding of the valve becomes an easy operation. On rare

occ i aeions t is necessary to grind the valve box into its seat in the cylinder. When this becomes needful, the small' dowel peg which locks the seat should be tapped in until it is flush with the circular part of the box: the latter can then easily be rotated. When the grinding is completed the driver must not forget to tap out this dowel peg into its original position.

Over lubrication of the camshaft case may cause

sticking by the lubricating oil getting on to the valve stems. As a precaution against this, it is advisable to squirt a little paraffin on to the exhaust valve stems at the close of each day.

Before opening up the valve gear, the engine should be turned by hand until the slots in the phosphor-bronze ball which form a part of the universal joint transmitting the motion from the crankshift to the timing gear are parallel or at right angles to the longitudinal centre line of the engine. The engine shaft must not be turned until this case has teen replaced, or the timing will be upset. After the valves have been ground in or any other adjustments have been made, it is advisable to check over the clearance between tappets and valves, for ‘vhich purpose the Mandslay Co. provides as part of the tool kit with each wagon a special gauge which

• takes the form of a 12 in. folding rule, the two arms of which are of different thicknesses, one showing the requisite clearance between the inlet valves and its stem, the other that between the exhaust valve and its stem. The tappet screws should occasionally lcexamined for looseness.

Turning to the other parts of the engine, both fan and water pump are driven by V belts. The tension of these belts should be tested occasionally, and, if necessary, adjusted, so that there is no slip. The gland nuts on the water pump should now and then be screwed up 'so as to prevent leakage along the spindle. In frosty weather, when emptying the radiator, open the tap at the bottom of the pump.

The magneto itself is adjusted by moving the magneto horizontally on its bracket. For this purpose it is carried on 17. slots, and special adjustment screws are provided.

Clutch.

The Maudslay clutch is of the cone type, leather lined and inverted. To keep the clutch in good con dition, a small quantity of collan oil should be applied occasionally, the car being left with the clutch held out and fixed in that position so as to allow time for the oil to penetrate the leather.

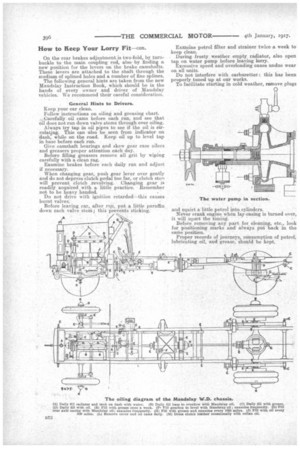

The Brakes.

Ready means of adjustment are provided for both the propeller shaft and the rear axle brakes. These means are depicted on our illustrations. With regard to the former, adjustment is by means of a circular nut which appears at the side of the chassis. After the brake lining has worn a little, it will be necessary to alter the set screws carried on the underframe which serve to position the brake shoes concentric . with the drum. As is standard on W.D.

vehicles, an arrangement is provided whereby I ater can be made to drip on to the inside of the drum; this need only be used on long hills. On the rear brakes adjustment, is two-fold, by turnbuckle to the main coupling rod, also by finding a new position for the levers on the brake camshafts. These levers are attached to the shaft through the medium of splined holes and a number of fine splines. The following general hints are taken from the new Maudslay Instruction Book, which should be in the hands of every owner and driver of Maudslay vehicles. We recommend their careful consideration.

General Hints to Drivers.

Keep your car clean.

Follow instructions on oiling and greasing chart.

Carefully oil cams before each run, and see that oil does not run down valve stems through over oiling. Always try tap in oil pipes to see if the oil is circulating. This can also be seen from indicator on dash: while on the road. Keep oil up to level tap in base before each run.

Give camshaft bearings and skew gear case oilers and greasers proper attention each day.

Before filling greasers remove all grit by wiping carefully with a clean rag.

Examine brakes before each daily run and adjust if necessary.

When changing gear, push gear lever over gently and do not depress clutch pedal too far, or clutch stort will prevent clutch revolving. Changing gear is readily acquired with a little practice. Remember not to be heavy handed.

Do not drive with ignition retarded—this causes burnt valves.

Before leaving car, after run, put a little paraffin down each valve stem; this prevents sticking. Examine petrol filter and strainer twice a week to keep clean.

During frosty weather empty. radiator, also open tap on water pump before leaving lorry.

Excessive speed and overloading cause undue wear on all units.

Do not interfere with carburetter : this has been properly tuned up at our works. To facilitate starting in cold weather, remove plugs and squirt a little petrol into cylinders. Never crank engine when lay-casing is turned over, it will upset the timing. Before removing arty part for cleaning, etc., look for positioning marks and always put back in the same position.

Proper records of journeys, consumption of petrol, lubricating oil, and grease, should be kept.