BUILDING UP DAY BY DAY

Page 36

Page 37

If you've noticed an error in this article please click here to report it so we can fix it.

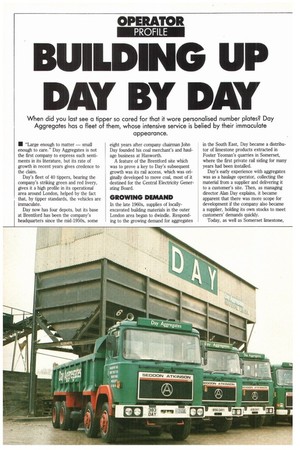

When did you last see a tipper so cared for that it wore personalised number plates? Day Aggregates has a fleet of them, whose intensive service is belied by their immaculate appearance.

• "Large enough to matter — small enough to care." Day Aggregates is not the first company to express such sentiments in its literature, but its rate of growth in recent years gives credence to the claim.

Day's fleet of 40 tippers, bearing the company's striking green and red livery, gives it a high profile in its operational area around London, helped by the fact that, by tipper standards, the vehicles are immaculate.

Day now has four depots, but its base at Brentford has been the company's headquarters since the mid-1950s, some eight years after company chairman John Day founded his coal merchant's and haulage business at Hanworth.

A feature of the Brentford site which was to prove a key to Day's subsequent growth was its rail access, which was originally developed to move coal, most of it destined for the Central Electricity Generating Board.

GROWING DEMAND

In the late 1960s, supplies of locallyexcavated building materials in the outer London area began to dwindle. Responding to the growing demand for aggregates in the South East, Day became a distributor of limestone products extracted in Foster Yeoman's quarries in Somerset, where the first private rail siding for many years had been installed.

Day's early experience with aggregates was as a haulage operator, collecting the material from a supplier and delivering it to a customer's site. Then, as managing director Alan Day explains, it became apparent that there was more scope for development if the company also became a supplier, holding its own stocks to meet customers' demands quickly.

Today, as well as Somerset limestone, Day distribute limestone-clay, which is brought in by rail (mainly from Leicestershire), and granite from Yeoman's new Glensanda quarry in Scotland. It also supplies sand from Surrey pits which is brought into Brentford by road, usually in the company's own tippers, as backloads.

Since 1983 the volume of aggregates supplied by Day has virtually doubled, to over 6,000 tonnes a day. The size of the fleet has grown accordingly and storage capacity at Brentford is also to be doubled, to 80,000 tonnes, helped by the installation of two more conveyor-fed overhead-loading hoppers holding 1,000 tonnes apiece. A further weighbridge is being acquired and trains carrying up to 4,000 tonnes will be able to discharge their loads in under three hours using bottom-discharge wagons.

Since 1983 new Day depots have opened at Purfleet, Essex and Woking, Surrey, but the company's most exciting recent development has been the commissioning of a seaborne terminal on the Isle of Grain in Kent, where it is set to play a significant role in the supply of materials for the Channel Tunnel.

Under its distribution agreement with Foster Yeoman, Day supplies the group's limestone and granite products, primarily in Surrey, Kent and the south of the London area: Yeoman Aggregates serves the area immediately to the north.

Materials other than those from Foster Yeoman are delivered over a much wider radius, typically out to Reading, Watford and Godalming.

Of the 40-odd tippers run by Day, 12 are directly owned. They include a number of Seddon-Atkinson eight-wheelers, whose ruggedness and reliability has been proved over a long period says Chris Driscoll, who has been responsible for Day's transport operations for 20 years.

Early Seddon 401 30-tonners in the fleet had heavy Cummins 14-litre NHC250 engines. Switching to Rolls-Royce (now Perkins) Eagle power units gave a small payload advantage — but the latest Seddon 3-11 8x4 to be commissioned, with a Cummins L10-290 engine, tips the scales at 9,900kg, a full tonne lighter than the original 14-litre models. All-aluminium 14m3 Charlton bodies also play their part in keeping down tare weights.

DEPENDABLE SERVICE

Dependable service from an L10-220powered Seddon 301 six-wheeler clinched the choice of chassis for the newest 8x4 tipper in the fleet, which was supplied, like other recently-acquired Seddons, through Swan Trucks of Hitchin.

At the Isle of Grain depot, where two company-owned eight-wheelers were needed, Day opted for Leyland rather than Seddon chassis, because of the dealer service support available in the area. The Constructor 30.27s are powered by the charge-cooled Eagle 265 engine, which gives the extra performance needed for the greater distances travelled over the less congested roads in the north of Kent.

Access for multi-wheelers is often difficult at construction sites in the London area, so Day has a 16-tonner on the fleet — a two-year-old Mercedes 1617K with a 7m3 Charlton body. In Chris Driscoll's view the eight-wheelers and six-wheelers in the Seddon range are better proven for

tipper operation than their two-axled stablemates. The Mercedes tipper has stood up well to the punishment to which all aggregate tippers are subjected and a second 1617K is now on order, from Normand Euro Trucks of Feltham.

Routine servicing is handled in-house at Brentford. To cope with the expanding fleet the two-bay workshop is to be extended to take three vehicles at a time. As Alan Day explains, the company's investment programme in recent years has had to be planned strategically, with the new depots and extension of the Brentford plant claiming priority over new vehicle acquisition.

As a result much of the extra capacity needed to handle the extra volume of materials has been supplied by outside contractors, working for Day on a sufficiently regular basis for them to paint their vehicles in the company's livery.

Many of the regulars are ownerdrivers, and Driscoll says that the company is selective in its choice of outside operators, to safeguard its reputation and image with customers, not least through maintaining the tippers' smart appearance: "We endeavour to see that each tipper in the fleet — whether our own or an outside haulier's — is cleaned every 24 hours", he says, adding that a dirtencrusted tipper attracts unwelcome attention from the authorities.

Efforts are also made to ensure that the owner-drivers and the bigger outside regulars — like Alan Dutton with five Dayliveried tippers, including some new FL Volvos — adhere to the company's standard of maintenance and overall mechanical fitness. Day's routine maintenance programme is geared to a 9,600Icm service interval for all makes of chassis.

Increasing fleet utilisation by carrying back-loads, notably sand, gravel and shingle from the Surrey "sand belt" back to Brentford, has been made easier by equipping the fleet with the Band-3 twoway communications system.

E by Alan Bunting