Making the me out of a tipper

Page 34

Page 35

Page 36

If you've noticed an error in this article please click here to report it so we can fix it.

THE DRAWBACK with special purpose vehicles is that they are "special purpose." More often than not, they cannot be used for anything but the traffic for which they were designed.

This applies particularly to tanker vehicles among units used for bulk transport, but it applies to tippers, also, to a lesser degree.

However, it is possible, by paying careful attention to bodywork, to design a tipper so that it can fulfil the dual role of bulk carrier and general purpose vehicle.

One organisation which has achieved this objective is R. H. M. Agriculture Limited whose associated firm, Hasler and Co Ltd. operates a tipping vehicle of 24 tons gross for transporting grain. It can be converted to carry bagged products on pallets, too.

Hasler is an agricultural merchant based at Great Dunmow, in Essex, providing a service to farmers and food manufacturers in East Anglia and London. The company's fleet comprises 40 vehicles ranging from maximum capacity articulated combinations with tipping trailers to flat-bed trucks.

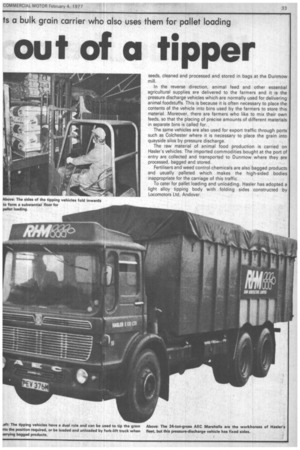

The -workhorsesof the fleet are undoubtedly the 24-ton-gross six-wheel AEC MarshaIls of which there are two types; one provided with pressure discharge and the other with a tipping body having folding sides for increased utilisation.

The company is engaged, basically, in carrying grain from farmers' premises to mills or storage and the delivery of seec animal feeds, fertilisers and weed control chemicals to farmers.

Its operation covers the whole of Essex, parts of South Suffol and Hertfordshire, and London. Despite the comparatively shoi journeys involved, its vehicles average some 30,000 miles a yea' A large proportion of the company's traffic is carried in its own fle€ though there is some hiring-in particularly at harvest time, as miglbe expected.

Farmers' grain crops are bought on a contract basis an Hasler's vehicles pick up the stored grain from the farm as th demand arises. Some of the produce is collected as it is harvester but the majority of collection is from storage.

The bulk vehicle are of the open top variety with a protectin sheet and they are filled either from overhead storage bins ( mechanically by hoppers. Some of the grain is taken directly to th mill or for export to the ports or it is brought into the company Dunmow premises for processing. Food manufacturers, such ( those producing breakfast cereal, maltsters and brewers are al( supplied.

A proportion of the grain is retained for next year's seed and this case it is important that absolute clearance of the vehicle achieved between loads of different varieties to preve incompatible seed mixtures. The seed grain is freed from we seeds, cleaned and processed and stored in bags at the Dunmow mill.

In the reverse direction, animal feed and other essential agricultural supplies are delivered to the farmers and it is the pressure discharge vehicles which are normally used for delivering animal foodstuffs. This is because it is often necessary to place the contents of the vehicle into bins used by the farmers to store this material. Moreover, there are farmers who like to mix their own feeds, so that the placing of precise amounts of different materials in separate bins is called for.

The same vehicles are also used for export traffic through ports such as Colchester where it is necessary to place the grain into quayside silos by pressure discharge.

The raw material of animal food production is carried on Hasler's vehicles. The imported commodities bought at the port of entry are collected and transported to Dunmow where they are processed, bagged and stored.

Fertilisers and weed control chemicals are also bagged products and usually palleted which makes the high-sided bodies inappropriate for the carriage of this traffic.

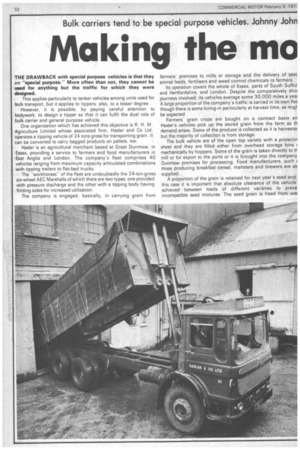

To cater for pallet loading and unloading, Hasler has adopted a light alloy tipping body with folding sides constructed by Locomotors Ltd, Andover.

Mounted on AEC Marshall chassis, they are equipped with Edbro double-ram tipping gear and discharge through a small sliding door at the rear.

For use with palletised goods, the sides of the vehicles are folded inwards to form a substantial floor. This is a simple procedure which involves only removing the sheet and the transverse ribs which support it to enable the sides to be repositioned. By folding the sides inwards, they are removed from an possible contact with the running gear and they protect the originE floor from damage so that tipping discharge is not inhibited.

With the sides lowered, the rear and forward bulkheads remai in position for greater load security.

Tony Doggett, in charge of transport at Hasler, told me that th AEC Marshall has been, traditionally, the most suitable vehicle fc this kind of work and that the additional 2 tons by which th vehicle was uprated had been very useful.

The company had been able to negotiate the difficult accet often found on farms and, though this problem is diminishin, because of improvements to their premises undertaken by farmer during the past few years, there are still some farms into which it i virtually impossible to get less versatile vehicles with comparabl payloads.

Because of the significant proportion of off-the-road work I which the vehicles are subject, becoming bogged down is an evi present hazard. With a heavily laden bulk grain vehicle, th presents special problems.

It is due to trying to pull a heavily laden vehicle out of such plight that damage to the vehicle often occurs. Yet lightening tf load in such circumstances can be difficult and, if undertak€ manually, become a tedious, time-consuming job.

To simplify the operation, Hasler has built a recovery vehicle c a Seddon tractive unit chassis to its own design.

It incorporates a two-way blower so that by connecting hosepir to the inlet and outlet apertures the driver can discharge the loE from a bogged-down vehicle directly into an adjacent replaceme vehicle.

The fifth-wheel coupling has been replaced by a tw tipping-ram assembly to which are attached two steel beams wi lifting hooks fitted at the end.

Once the bogged-down vehicle has been discharged it is comparatively simple matter to position the hooks at the front rear of the chassis and lift tow it out of trouble.

This ingenious vehicle has been built by Hasler's own staff wi redundant material.