Patents Completed.

Page 24

If you've noticed an error in this article please click here to report it so we can fix it.

, Foppe Duplex Carburation. Leitner Starting Gear. A Two-stroke Engine.

T. GARE, N. 25,719, dated 9th November, 1912—cognate Application No. 653/1913.—The base of the tire is made of hard rubber, or hard rubber arid canvas, and is secured to a. metal band by various means. Washers, or plates, on the upper side of the hard rubber base are provided with holes through which rivets or screws are passed to engage the rim. The rubber tread is vulcanized direeti;' on to these plates and to the rubber base. In another construction, circumferential grooves are formed to the inner rubber band, and steel wires in these grooves are passed around the wheel. The tread is vulcanized directly on to the base, and the grooves give it a good grip. In one modification only a canvas base is used, a hand of some suitable material being fixed around the canvas, carrying a number of projections which embed themselves into the tire, which is vulcanized on to the band.

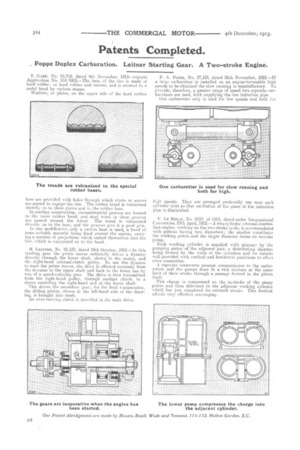

H. LE2TNER, No. 23,157, dated 10th October, 1912.—In this starting gear the prime mover ordinarily drives a dynamo directly through the lower shaft, shown in the casing, and the right-hand internal-clutch pulley. To use the,:dynamo to start the prime mover, the drive is effected reversely from the dynamo to the upper shaft and back to the lower one by way of a speed-reducing gear. The drive is then transmitted from the right-hand pulley, through another clutch, to a sleeve encircling the right-hand end of the lower shaft.

This drives the secondary gear; for the final transmission, the sliding pinion, shown at the left-hand side of the drawing, is brought into mesh. An over-running clutch is provided in the main drive.

P. A. POPPE, No, 27,153, dated 26th November, 1912.—If a large carburetter is installed on an etigineitooenable high epee& to be,obtained the slow running is unsatisfactory. To provide, therefore, a greater range of speed two separate carburetters are used, both supplying the one induction pipe.

One carburetter only is used for low speeds and both for high speeds. They are arranged preferably one near each cylinder inlet so that oscillation of the gazes in the induction pipe is diminished.

Y. LE BIHAN, No. 9157, of 1913, dated under International Convention, 27th April, 1912.—A two-cylinder internal-eom bustion engine, working on the two-stroke cycle, is accommodated with pistcns having two diameters ; the smaller constitutes the working piston and the larger diameter forms an annulai pump.

Each working cylinder is supplied with mixture by th: pumping piston of the adjacent pair, a distributing chamber being formed by the walls of the cylinders and an outside wall provided with vertical and horizontal partitions to effect cross connection.

A separate transverse passage communicates to the carburetter, and the pumps draw in a rich mixture at the outer limit of their stroke through a passage formed in the piston This charge is compressed on the in-stroke of the pump piston and then delivered to the adjacent working cylinder which has just completed its outward stroke. This method affords very effective scavenging.