AEC Marshal 24

Page 42

Page 43

Page 44

Page 45

Page 46

If you've noticed an error in this article please click here to report it so we can fix it.

-gross eight-wheeler

AN INDICATION of the lack of interest that manufacturers have shown in eight. wheelers in the past few years is indicated by the fact that the last such vehicle to bt offered for road test was almost five years ago. Changes in regulations haw concentrated attention on artics but in the past six months there has been 2 resurgence of interest—illustrated at the last Commercial Motor Show—and there an signs that makers no longer consider the four-axle rigid a "deadmachine.

One of the new breed of eight-wheelers is the AEC Marshal and the results of a ful road test and operational trial of the 8 x 4 version show definite advantages for thil type of chassis as against a 24-ton-gross threeor four-axle artic. Comparing thc test results with those from an AEC Mercury /Scammell three-axle artic tested by CIV at the same gross weight, payload was greater, fuel consumption and braking wen better and there was not much difference in acceleration-test results.

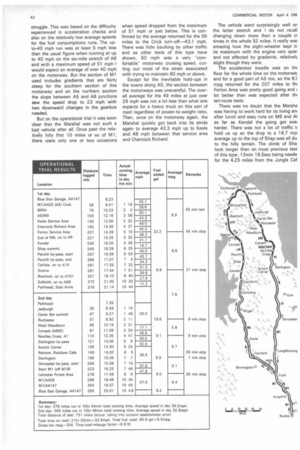

On the set-route tests the Marshal seemed very short of power and if a norma routine only had been carried out this would probably have been a criticism. But witt the operational trial giving much more of a chance to assess the design under actua working conditions this impression was largely removed. It did not take much of gradient to make a downward gear change necessary but the eight-wheeler woull maintain maximum speed for long stretches of motorway and completed the 731 -mil operational run in 21 hr 33min—less than 11 hr on each leg—for an average speed c 33.9 mph and at an overall fuel consumption of 8,5 mpg.

These were very good results and I would also praise the Marshal for well-designe steering and a low level of noise in the cab. The long journey was not over-tirin although I felt that the clutch and brake pedals required too much effort to operate bu a big advantage found with the eight-wheeler was in manoeuvrability. A short overa length as compared with a three-axle artic for the same weight made drivin! easier—particularly in the towns—and also eliminated difficulties that would hayl been experienced on a part of the route where deep snow reduced the usable width c the road to less than 16ft. There was not the problem that would have existel with a long artic when manoeuvring to pass vehicles that had come from the opposit direction. Snow lay on the actual road for only one short stretch, but where there wa deep snow at the sides in Northumberland and Durham, with the double-drive bogi we drove into it with no worry at all in order to allow oncoming trucks to pass.

The mechanical specification of the parking through a conventional singlE Marshal includes the engine and gearbox pull handbrake lever. There are doubl( as used in the Mercury tractive unit diaphragm brake chambers at the fir which was tested by CM in June 1967. steering axle and the rearmost axle of tf The AEC AV505 diesel produces 146 bhp bogie and the secondary sides of the: gross to the BS AU 141 standard at a are pressurized only when the lever governed speed of 2,200 rpm. Maximum applied. There is a valve at the retch gross torque to the same standard is 384 mechanism, the mechanical linkag lb. ft. at 1,300 rpm and the drive is being connected to the brakes on boi through an AEC six-speed overdrive gearrear axles.

box. The double-drive rear bogie has The test vehicle did not have a boc single reduction axles with a lockable which must be taken into account whE inter-axle differential. Power steering is considering the payload carried. TV standard. weights totalled 17 tons 3.5cwt whic The braking system of the Marshal has with two men in the cab brought tt a straightforward layout and the secongross weight to exactly 24 tons. With dary brake function is combined with driver only and a light-alloy body weigl ing about 16cwt, kerb weight would have been 7 tons 9.25cwt so allowing an actual payload of 16 tons 10.75cwt. This compares with 16 tons 2.5cwt possible on the Mercury 24-ton artic tested when running within the 24-ton limit.

Set-route fuel consumptions checks were made on A6 and M1 south of Luton and the results obtained were reasonably good. They were both about 0.5 mpg better than on the Mercury artic test with similar average speeds. It had been intended to check brakes and acceleration in the same area but the roads were wet and the relatively low power made acceleration checks impracticable because the very slight gradient on the road normally used—to all intents and purposes the road is flat--meant that the road was not long enough to get up to the speeds required.

It was therefore decided to leave these checks until the first day of the operational trial and make use of the facilities at MIRA. The road surfaces used there for the brake tests were still wet, which extended the stopping distances to some degree but the figures were very good in the circumstances. With peak efficiencies of around 70 per cent there was expected locking of the wheels; all of them locked on every stop—for about 8 or 91t from 20 mph and 15 /17ft from 30 mph. The handbrake /secondary brake effeciency at 50 per cent was very good. Acceptable performance figures were obtained on the one-mile-long acceleration straights at MIRA and the standard gradients were used for stop-and-restart checks, It was just not possible to restart the vehicle in first and reverse when facing up and down the slope respectively but the handbrake was more than adequate to hold the laden vehicle in both cases with the lever released and therefore with only mechanical application of the rear brakes.

As already stated the indication from the normal-type road test was that the Marshal was underpowered and that the operational trial would be something of a struggle. This was based on the difficulty experienced in acceleration checks and also on the relatively low average speeds for the fuel consumptions runs. The upto-40 mph run was at least 5 mph less than the usual figure when running at up to 40 mph on the six-mile stretch of 46 and with a maximum speed of 51 mph I would expect an average of over 40 mph on the motorway. But the section of M1 used includes gradients that are fairly steep for the southern section of this motorway and on the northern section the slope between 45 and 46 junctions saw the speed drop to 23 mph with two downward changes in the gearbox needed.

But on the operational trial it was soon clear that the Marshal was not such a bad vehicle after all. Once past the relatively hilly first 10 miles or so of Ml, there were only one or two occasions when speed dropped from the maximum of 51 mph or just below. This is confirmed by the average returned for the 56 miles to the Crick turn off-43.1 mph. There was little baulking by other traffic and as other tests of this type have shown, 50 mph was a very "comfortable" motorway cruising speed, cutting out most of the strain associated with trying to maintain 60 mph or above.

Except for the inevitable hold-ups in the towns along A5, the section between the motorways was uneventful. The overall average for the 49 miles at just over 29 mph was not a lot less than what one expects for a heavy truck on this sort of road regardless of power-to-weight ratio. Then, once on the motorway again, the Marshal quickly got back into its stride again to average 43.3 mph up to Keele and 48 mph between that service area and Charnock Richard. The vehicle went surprisingly well on the latter stretch and I do not recall changing down more than a couple co times in the whole 52 miles. It really was amazing how the eight-wheeler kept tc its maximum with the engine very quie' and not affected by gradients, relativel) slight though they were.

The accelerator treadle was on th( floor for the whole time on the motorwa) and for a good part of A5 too, so the 8. mpg returned for the 207 miles to thE Forton Area was pretty good going and lot better than was expected after thE set-route tests.

There was no doubt that the Marsha was having to work hard for its living am after lunch and easy runs on M6 and Al as far as Kendal the going got eve' harder. There was not a lot of traffic ti hold us up so the drop to a 16.7 mp average up to the top of Shap was all du to the hilly terrain. The climb of Sha took longer than on most previous test of this type, 13min 19.5sec being neede for the 4.25 miles from the Jungle Caf e summit. Second gear was needed he steepest-1 in 9—section with speed down to 7 mph. For most of long final "drag", road speed was reen 8 and 10 mph with increase to I 5 mph for a less-steep part.

ter Shap it was all fairly easy going o Gretna—the hard work had only 1:ed fuel consumption to 8.8 mpg -id the same applied as far as Lock. Here a turn on to A701 is to go over the Tweedsmuir Hills on way to Dalkeith. This part of the ey went very well and the light ing played an important part in taming a good average of 27.9 mph us twisting route. The bends could ken without a big reduction in speed after darkness fell good headlights )d also. Pathead was reached after

10hr 44min actual running time making the average for the 376 mile day's work a commendable 35.2 mph.

We started the second day's run with warnings of heavy snow on A68 and reports of snow ploughs still out on Carter Bar. Fortunately there were no signs of these bad conditions while we were in Scotland. The 1.82-mile climb of Carter Bar was made in 8min 53sec, the main gradient being taken in third at around 14 mph—this gear was just right for the 1 in 13/14 slope. Near the top where there is an increase to 1 in 10 a change to second gear was needed and the speed dropped to 8 mph. At the start of the hill, road speed was 38 mph and at the top it was 14 mph.

Most of the climb had been made in heavy mist and as soon as we got over the top we reached the real snow to add to the difficulty. The road surface itself was not too bad—patches of broken up packed snow and slush —but there were deep drifts on each side which had not been cut back to the road edges. Road speed had to be kept down but we were lucky not to meet any heavy vehicles on our way up. There was in fact only one difficult moment when I had to take to the snow to get past an oncoming car.

In spite of the snow and misty conditions—which cleared up soon after Carter Bar—and the resulting need to keep speed down, a good average of 26 mph was made to the first fuel fill-up of the second day at Rochester. This showed a respectable 7.6 mpg for the run from Gretna.

Climbing again

Soon after Rochester we were climbing again and into more snow after West Woodburn. Except for a couple of miles on each side of Corbridge there was a considerable amount of deep snow on both sides of the road and although the road surface itself was completely clear the road width was in the main much reduced to less than 14ft in places. At one point the ploughs had cut through drifts above cab height so we counted ourselves lucky at being able to complete the run at all. As it turned out there was only one real delay to progress, this being when we were held up while a vehicle in front of the AEC spent more time than he should have needed to get past an oncoming six-wheeler. The time wasted was not deducted from the running time which made the average to Consett 17.1 mph. But I do not think the average would have been above 20 mph in normal conditions.

The time for climbs of the steepest hill on A68—Riding Mill was recorded. The 0.6-mile long hill has a maximum gradient of 1 in 5 and the climb took 4 min 58sec with first gear needed for the short, steepest part when the road speed dropped to 4 mph. It had been intended to time the climb of Castleside Hill just before the turn to Consett which has a similar maximum gradient-1 in 5.25—and is a little longer. But a welloverloaded Albion was finding the climb almost too much and we could not manage to overtake.

At Consett the really hard work was over and a fill-up at Nevilles Cross just after reaching Al showed that the steep and frequent gradients of A68 had taken their toll—fuel usage for the 53 miles from Rochester worked out at 5.8 mpg.

The Marshal made good progress on Al and returned a good fuel consumption at 9.7 mpg. And when on the motorway the consumption did not drop too much even though the part north of Leicester Forest is fairly hilly. In spite of the gradients and the fact that speed had dropped to 15 mph in third gear on the long slope coming up to the A50 turn for Leicester, the average was 47.8 mph. This was, in fact, slightly higher than the average for the easier, southern section although consumption improved there to reach 9,4 mpg.

On the second day, the 355 miles had taken 10hr 49min total running time for an average speed in the day of 32.8 mph and the overall average speed for the 731-mile run worked out at 33.9 mph with the overall fuel consumption 8.5 mpg.

Good figures

These are good figures considering the road used for the test. As I have said, the time I spent in the cab—sharing the driving with Arthur Hollands of AEC—did not produce undue fatigue. The Marshal' had to be "driven" to get the best out of it but the work was kept to a minimum by the power steering which was light yet positive although on some surfaces that were uneven there was some feeling of floating which could have been due to the tyre equipment. The suspension was very good and the accelerator pedal was well placed and light but the clutch was heavy, needing 80Ib pressure to release. The brake pedal was also heavy to apply and there was lack of response. I would imagine that brake application in the unladen condition would be rather tricky,

Except for first and reverse, the gear change action was light and it was not difficult to make clean changes although the engine was slow to die down and when changing up one had to be patient and allow some time to elapse before engaging the next ratio. This made for no difficulty when going through the box on the flat or downgrade but on a long hill such as Shap where the gradient eases off in places changes up are desirable and in these cases the only solution was "snatch" changes; these were possible on the Marshal without too much noise.

Standard of comfort

The standard of comfort in the Ergomatic cab is very high (although there is not much elbow room for the passenger) and visibility is good—but see below. The mirror equipment was adequate with a convex glass on the nearside and a flat mirror on the offside. With the mirrors positioned well forward they picked up no dirt from the road, but with a lot of spray about the sides of the cab the side and rear windows got covered in muck and needed frequent cleaning.

It was fairly cold on the two test days and although the Marshal has a high output heater, insufficient warmth reached the foot-well areas. The situation was not helped by draughts coming from various points under the dash. On the passenger side there was a big gap in the corner at the forward end of the engine cover which was satisfactorily stuffed with rags, but cold air coming through the heater control on the driver's side could not be cured and the source of a another cold blast from above the accelerator pedal could not be located.

Mechanically, the Marshal gave no trouble. There was some out-of-balahce in one of the propeller shafts which caused periodic vibrations and a rattle developed in the change speed linkage halfway through the test which was felt to be slackness of a shaft in the change-speed box. No doubt the amount of gear change work and "snatch" changes had caused this and the rattle was exaggerated by the propeller shaft vibration. This was worst at 48 mph in top and caused vibration of the offside mirror. There were also two minor electrical faults. The nearside side lamp failed early on and on the last lap the flashing direction indicators became inoperative.

The conclusion reached after this test must be that the eight-wheeler still has a place on the British transport scene. The Marshal should be a profitable vehicle to operate and likely to give reasonable consumption at quite adequate average speeds. The lightweight design gives the big advantage of maximum payload within the 24-ton limit considering both rigids and artics, and although some operators may prefer the heavier AEC Mammoth Major eight-wheeler with its 183 or 200 bhp engine there is the extra 10cwt unladen weight and £340 extra list price that have to be taken into account. The Marshal chassis/cab tested has a basic price of £4,655.