Centrifugal Clutch for Daimler

Page 47

If you've noticed an error in this article please click here to report it so we can fix it.

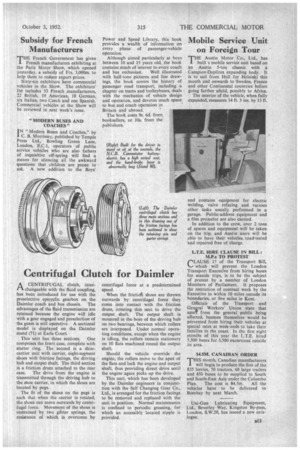

ACENTRIFUGAL clutch, interchangeable with the fluid coupling, has been introduced for use with the preselective epicyclic gearbox on the Daintier coach and bus chassis. The advantages of the fluid transmission are retained because the engine will idle with a gear engaged and preselection of the gears is still operative. A sectional model is displayed on the Daimler stand (71) at Earls Court.

This unit has three sections. One comprises the front case, compfete with starter ring. The second is a shoecarrier unit with carrier, eight-segment shoes with friction facings, the driving hub and output shaft. The third section is a friction drum attached to the rear case. The drive from the engine is transmitted through the driving hub to the shoe carrier, in which the shoes are located by pegs. • The fit of the shoes on the pegs is such that when the carrier is rotated, the shoes can move outwards by centrifugal force. Movement of the shoes is restrained by two gdrter springs, the resistance of which is overcome by centrifugal force at a predetermined speed.

When the frictiof shoes are thrown outwards by centrifugal force they come into contact with the friction drum, rotating this unit to drive the output shaft. The output shaft is mounted in the bote.of the driving hub on two bearings, between which rollers are interposed. Under normal operating conditions, except when the engine is idling, the rollers remain stationary on 10 flats machined round the output shaft.

Should the vehicle override the engine, the rollers move to the apex of the flats and lock the engine and output shaft, thus providing direct drive until the engine again picks up the drive.

This unit, which has been developed by the Daimler engineers in conjunction with the Self Changing Gear Co., Ltd., is arranged for the friction facings to be removed and replaced with the unit in position. Normal maintenance is confined to periodic greasing, for which an accessibly located nipple is provided.