REIM the Orewinq Boer

Page 52

Page 53

If you've noticed an error in this article please click here to report it so we can fix it.

by Graham Montgomerie

5-1WINTER was exceptioly severe not only because of lormally low temperatures, also because it lasted well ) "spring". This long cold iod caused many problems h diesel waxing blocking I lines and filters, making -ting impossible.

rhe British Technical Council he Motor and Petroleum Intries has published a booklet ing advice to operators of iel-engined vehicles on how irepare for winter operations. ) of its major recommendais is that anticipation is vital, t action should be taken re a cold spell sets in.

mposition

)iesel fuels are complex mix:s of hydrocarbons which e a boiling point in the range )° to 380cC (340° to )° F). The paraffin hydroons which form an essential of dery have only limited bility and, as the fuel cools, start to come out of solution le form of wax crystals. The )unt and type of wax deJs on the distillation range le fuel and the crude oil from Al it is produced.

flany of the oil companies try :ounteract this before the er starts by the use of ad es which interact with and lify the wax crystals which 1 as the fuel cools. These lified crystals are smaller less likely to clog up the am.

he temperature at which crystals start to separate I a diesel fuel on cooling is led the Cloud Point. If the

cools further, a temperature ,ached where there is suf

nt wax out of solution to a structure preventing the from flowing. This tempere is known as the Pour t.

either of these tempera; give a precise indication of

a diesel fuel will perform in ice as, in most instances: Cloud Point test gives a imistic reading while the Point gives an overrustic estimate.

estimate.

test has been developed to ?late with the lowierature performance which known as the Cold Filter Plugging Point (CFPP) test. The K, in common with other European countries, has açiopted this procedure to specify the low-temperature q ality of automotive diesel I iel.

In the CFPP test, a measured q antity of fuel is drawn through a fine mesh screen. The fuel is gradually cooled and the fi tration test repeated until the flow rate is considered inadequate. The temperature at which this occurs is known as the Cold Filter Plugging Point of t e fuel.

Dery supplied to the UK rket is required to conform to British Standard 2869 — "Petroleum Fuels for Oil Engines and Burners" — which specifies a maximum CFPP of 9°C (16°F) during the winter period and a maximum of 0°C (32°F) during the remainder of the year.

Production of winter-quality fuel commences well in advance of the specified "winter period" so that storage tanks in the distribution network should be replenished with the correct grade by the time the cold weather starts.

The fuel specification can be altered in several ways at the refinery. For example the distillation end-point can be low ered to eliminate some of the high-boiling paraffinic hydrocarbons. While this is very effective in lowering the Cloud Point it unfortunately reduces the amount of winter grade dery which the refiner can produce -frm a given quantity of crude oil.

Another refinery practice iS to incorporate kerosine to increase the solubility of the fuel for the waxing components, The refiner can use kerosine as the blend can be correctly taxed, but as kerosine is taxed differently from derv, its use by operators for road vehicles is illegal in the UK.

The blending of kerosine in .diesel has to be limited anyway because of flash-point considerations. Furthermore, the use of large quantities will lead to recduced economy and power and can have an adverse effect on injection equipment due to its lower viscosity compared with derv.

Flow additives

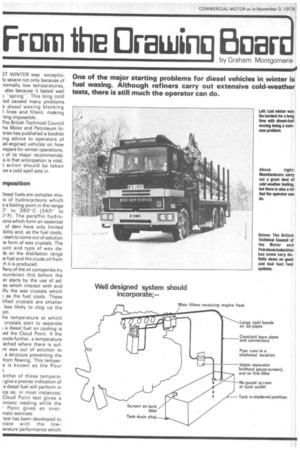

A further approach is the use of flow improver additives. These must be added when the fuel is above its Cloud Point and free of undissolved wax. Wax crystals already present cannot be effectively modified so it is definitely a case of "prevention being better than cure" In many cases the depot storage tank is out in the open and exposed to extremes of temperature. Protecting the pipework with some form of water-proofed insulation is to b recommended. If a strainer i fitted, it should be of a large are and fairly coarse (50 micrometres, 30 mesh). Ar other important point is to er sure that the fuel take-off poir is well above the tank bottom.

To avoid picking up wet( and debris that may have acct mulated, the British Technict Council suggests draining th tank at intervals, particularl just before the. onset of winter.

If practicable, vehiclE should be garaged overnigh Obviously this is impossible i most cases, so parking th trucks so they are not fully e: posed to the wind is a mus Temporary lagging of fuel tanl and lines in these circumstance would be helpful.

If fuel starvation due waxing should occur, howeve the BTC recommends the fa lowing action to get the fu, moving again: (a) Change the fuel filter ell ment, and clean and dra the water separators. If 0vehicle can be restarted, extended idling period wi' the cooling air flow res rimed can be beneficial.

(b) If possible, get the machine or at least the fuel system • warm in order to dissoh the wax and melt the ice.

(c) Where practicable refill tt fuel system, after drainag with the grade of fu apvepriate to the amble conditions.

The BTC stresses that tt operator should always use ti correct grade of fuel relative the expected temperatures. Tl is all very well for the larg operator buying in bulk from tl oil companies, but the own driver is reliant upon tl efficiency of his local filling Si tion in making sure the corre fuel is available. The period availability as far as the oil cor panies are concerned is fro October to February inclusive.

The main message from ti BTC to operators is that regul maintenance and comm( sense can do much to redu cold-weather problems wi diesel powered equipment.

The BTC booklet, referen BTC/F1 /79, may be obtain from the BTC Secretariat, MIR Watling Street, Nuneaton, W wickshire CV10 OTU. The cc is on a sliding scale basis w quantities up to five being per copy plus postage; six to copies being E1 each, and copies and above being avz able at 50p each.