Contributions from Drivers and Mechanics.

Page 18

Page 19

If you've noticed an error in this article please click here to report it so we can fix it.

TEN SHILLINGS WEEKLY for the Best Communication Received, and One Penny a Line of ten words for any thing else published.

Drivers of commercial-motor vehic.es and tra:tors, and mechanics and foremen of garages OY shops, are invited to send short contributions on any subject which is likely to prove of interest to our readers. Workshop tips and smart repairs ; long and successful runs ; interesting photographs : all are suitable subjects. Send a post-card, or a letter, or a sketch to us—no matter how short, or how written, or how worded. We will "knock it into shape" and prepare sketches, where necessary, before publication. The absence of a sketch does not disqualify for a prize. When writing use one side of the paper only and mention your employer's name as a guarantee of bona fides. Neither your own nor your employer's name will be disclosed. Payment will be made immediately after publication. Address your letters to The Editor, THE CONIMERCIAL MOTOR. 7-15, Rosebery Avenue, London, E.C.

Stretching a Pipe.

The sender of the following communicatiin has been awarded the 10s. prize this week.

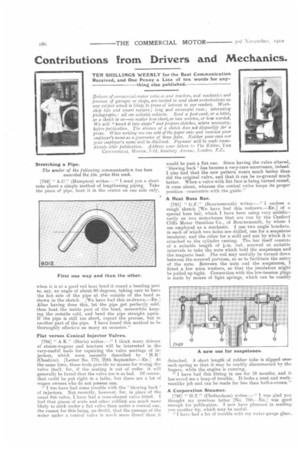

[783] " A.C." (Hampton) writes :—" I send you a short note about a simple method of lengthening piping. Take the piece of pipe, heat it in the centre on one side only, when it is at a good red heat bend it round a bending post to, say, an angle of about 90 degrees, taking care to have the hot side of the pipe at the outside of the bend as shown in the sketch. [We have had this re-drawn.—En.] After having done this, let the pipe get perfectly cold, then heat the inside part of the bend, meanwhile keeping the outside cold, and bend the pipe straight. again. If the pipe is still too short, repeat the process, but in another part of the pipe. I have found this method to be thoroughly effective on many an occasion."

Flat versus Conical Injector Valves. _ [784] " A.K." (Herta) writes;—" I think many drivers of steam-wagons and tractors will be interested in the very-useful tools for repairing the valve seatings of injectors, which were recently described by 'HB.' (Cheshire). [Letter No. 770, 29th September.—En.] At the same time, these tools provide no means for truing the valve itself, for, if the seating is out of order, it will generally be found that the valve too is as bad. Of course. that could be put right in a lathe, but there are a lot of wagon owners who do not possess one.

" I too have had some trouble with the f blowing back ' of injectors. Not recently, however, for, in place of the usual flat valve, I have had a cone-shaped valve fitted. I find that pieces of scale and other rubbish are much more likely to stick under a flat valve than under a conical one. the reason for this being, no doubt, that the passage of the water under a conical valve is moil more direct than it

would be past a fiat one. Since having the valve altered, blowing back' has become a very-rare occurrence, indeed. I also find that the new pattern wears much better than did the original valve, and that it can be re-ground much better. When a valve with flat face is being turned round, it runs about, whereas the conical valve keeps its proper position—concentric with the guide."

A Neat Buss Bar.

[785] " G.F." (Bournemouth) writes :—" I enclose a. rough sketch [We have had this redrawn.—En.] of a

special buss bar, which I have been using very satisfactorily on two motorbuses that are run by the Canforcl

Cliffs Motor Omnibus Co., of Bournemouth, by whom I am employed as a mechanic. I use two angle brackets, in each of which two holes are drilled, one for a soapstone insulator, and the other for a staid and nut by which it is attached to the cylinder casting. The bar itself consists of a suitable length of t-in. rod, screwed at suitable intervals to take the nuts which hold the soapstones and the magneto lead. The rod may usefully be turned down between the screwed portions, so as to facilitate the entry of the nuts. Between the nuts and the soapstones, I fitted a few mica washers, so that the insulators might be pulled up tight. Connection with the low-tension plugs is made by means of light springs, which can be readily

detached. A short length of rubber tube is slipped over each spring so that it may be readily disconnected by the fingers, while the engine is running.

I have had this fitting in use for 18 months, and it has saved me a heap of trouble. It looks a neat and workmanlike job and can be made for less than half-a-crown.'

A Corporation Steamer.

[786] " H.T." (Cheltenham) writes :—" I was glad you thought my previous letter [No. 760.—En.] was good' enough for publication. I now have pleasure in sending you another tip, which may be useful.

"I have had a lot of trouble with my water-gauge glass,

which is a flat one and about 3 in. long and in. thick. It has a washer back and front ; the back one was of Woodite, and the front one of asbestos. The trouble was that the back one was constantly blowing out after about three weeks' wear. I tried several remedies which were not successful. One day, however, I mentioned it to a driver friend and he gave me some black sheet jointing, called 'Tonkin, 1-16th in. thick. I cut a washer out of it to the size required, and I put it in the fitting and the glass on top of that. I next put the asbestos washer on and then the top of the fitting and screwed it all down. I have never had any trouble since. One day I had occasion to pull the gauge to pieces, and, found that I should have to have broken the glass to have parted it from the washer and the brass.

" I am enclosing photo. of my engine. [We reproduce this herewith.—En. 3 It is a patching roller of a special design which can be made heavier or lighter, from 6 tons to 10 tons, by means of removable cast-iron weights, according to the work we have to do. We carry a ton of water tor spraying patches, when repairing roads. I can reverse, with steam on, 30 times in a minute if required, although, of course, my ordinary work on the highways requires nothing like that speed."