Frame up...

Page 93

Page 94

If you've noticed an error in this article please click here to report it so we can fix it.

First find the cause for chassis strain

PERHAPS two or three times in the operational life of a transport man one or other of his vehicles suffers that most serious of failures — a fractured chassis frame. The reasons for such a failure are numerous, and one should never jump to conclusions. It could be that a failure was caused by faulty material or bad assembly, incorrect body mounting, holes drilled in unacceptable places, overloading or other forms of abuse.

Whatever the reason, the effect is serious and immediate. Quite rightly, it warrants attention straight away and if spotted by the authorities will collect you an immediate GV9.

It is essential that we find out why the fracture has occurred before we take action in repairing it. If we don't then it will be only a short time before the crack appears once more. And the more times the frame is repaired the more difficult it becomes and the weaker that particular area becomes.

So, the essential ingredients

in successful repair areIsolate the cause; carry out a proper repair.

Critical areas

There are many pointers which can lead us to the critical areas just as there are those that will avoid a waste of effort looking at parts of the frame where it is highly unlikely that any failure will ever occur.

But why do frames crack in the first place? Although the designer is always very careful to dictate the frame size to cater. for the stresses which he is aware the vehicle will be subjected to, there appear in service a great number of unpredictable happenings which throw up equally unpredictable stresses. It is here that our really serious problems begin.

I can already hear the comments that if that situation is known why aren't the necessary dimensions built in to take account of them, and there's the rub, for while we require strong frames we also demand low unladen weight and price.

So in producing a vehicle manufacturers are faced with the need for constant compromise, and it is in this area that the biggest danger arises to your operator's future peace of mind.

Where to look

To return to the problem where to look, however, the first thing to remember is that the frame has more than one func tion. It is surprising how many transport people do not recog nise that fact and plod gamely on putting strength and weight where it is not needed while neglecting a critical area which will undoubtedly lead to future failures.

The same can be said for bodybuilders, some, of whom still regard weight as strength.

Nothing can be further from the truth, and in many cases this philosophy is totally responsible for future failures of the vehicle in one form or another.

The functions the frame has to perform are: to carry the load; to retain the alignment of axles and drive line; and to transmit the steering and driving forces from the respective axles to the mass of the vehicle. And, of course, last but not least, it also transmits the braking forces to the mass of the vehicle, So we see that our frame must be able to successfully and continuously withstand stresses placed upon it by many factors.

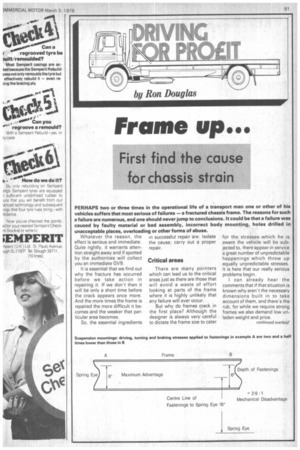

When the situation arises that one section of the frame is required to do one thing, while an adjacent part is trying.to force it to do something else we have a stress problem, and any short comings in the design or material will result in a failure.

This will occur at the point least able to withstand the stress, for instance at a change of section in the frame, or where the frame section is weakened by drillings. Alternatively at the point where the unit which is applying the opposing forces and the frame join.

Look for trouble

Section changes need not be in the actual pressing or rolling of the main frame; they can also be caused by the application of flitches or sub-frames or where the frame is inadvertently stiffened by heavy mounting brackets. The places to look for trouble are always in these areas and the wise operator makes sure that when deciding to purchase a new type or make of vehicle that despite what the salesman tells him, there are no hideously outstanding stress raisers in the assembly.

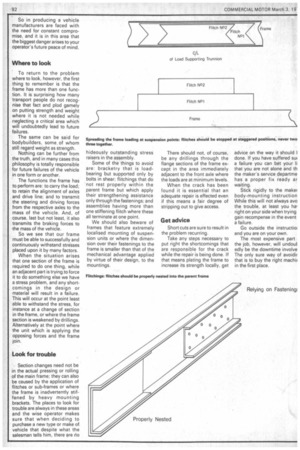

Some of the things to avoid are: bracketry that is loadbearing but supported only by bolts in shear; flitchings that do 'not rest properly within the parent frame but which apply their strengthening assistance only through the fastenings; and assemblies having more than one stiffening flitch where these all terminate at one point.

We should also beware of frames that feature extremely localised mounting of suspension units or where the dimension over their fastenings to the frame is smaller than that of the mechanical advantage applied by virtue of their design, to the mountings. There should not, of course, be any drillings through the flange sections of the frame except in the area immediately adjacent to the front axle where the loads are at minimum levels.

When the crack has been found it is essential that an adequate repair is effected even if this means a fair degree of stripping out to give access.

Get advice

Short cuts are sure to result in the problem recurring.

Take any steps necessary to put right the shortcomings that are responsible for the crack while the repair is being done. If that means plating the frame to increase its strength locally, get advice on the way it should t done. If you have suffered sut a failure you can bet your Ii that you are not alone and th the maker's service departme has a proper fix ready ar waiting.

Stick rigidly to the maker body-mounting instruction While this will not always avo the trouble, at least you ha, right on your side when trying gain recompense in the event a failure.

Go outside the instructioi and you are on your own.

The most expensive part the job, however, will undout edly be the downtime involve The only sure way of avoidir that is to buy the right machii in the first place.