One way round the 450km limit

Page 83

Page 85

Page 86

If you've noticed an error in this article please click here to report it so we can fix it.

Bill Brock tests Volvo's 8x2 30-ton rigid. Pictures by Mike Loveridge

ALTHOUGH Volvo's new 8x2 30-ton rigid was launched on the UK market only on February 10, CM has already tested a model with 50,000km (31,000 miles) on the clock.

We have been able to do this since the London Brick Company has had one of these Irvine-assembled models, on trial at its Bedford depot for the last eight months.

The model has a 6.4m (21ft) wheelbase and an unladen weight of 9.65 tonnes (9.5 tons) — including one ton of Selfstak loading gear.

London Brick says it runs fully laden at about 20 tons, a limitation imposed by the height of the stack rather than the dimensions of the light Freight Developments platform body.

Before our test, however, Chris Evans, Alilsa Trucks' market support engineer, ensured that the load was increased to just under the maximum weight of 30 tons gross, in fact, a payload of 20.5 tones, equal to that

of many 32-ton articulated vehicles.

Volvo has been able to achieve this with the eightwheeler by using an 18-ton single-drive rear bogie. The saving in weight is gained from the lighter construction of the bogie and from the electrohydraulic lifting rear axle consisting of stub axles only.

In operation a 12 / 1 8-ton split is not without its problem if, unlike our brick load, the cargo cannot be distributed evenly

over the complete load platform. To put it another way, this configuration fixes the centre of gravity of the vehicle and load to one point when running at maximum weight.

As it has been quite a while since I last drove on eightwheeler, I had once again to get used to this configuration's poor lock. I had to use all the available road space when driving out of a garage forecourt or coming to a narrow junction.

I mention the garage forecourts only because I had to try five before finding one which had fuel.

Fuel consumption

Despite the fuel shortage we were able to check the accuracy of the Flowmeter readings against a tank top-to-top test. Overall we returned a satisfying 36.2 lit/100km (7.79mpg), but on the slow hilly section from High Wycombe to Hemel Hempstead the figure was to 39.8 lit/100km (7.1mpg).

Frequent use of the Flower gear ratios was necessary on hills. The small — 6.7-litre (409cuin) — engine could be considered to be low on power, but on the road the versatility and ease of operation of the gearbox tended to disguise this fact.

Owing to snow at MIRA I was unable to determine the restart gradeability, but Volvo claims a restart is possible on a 1 in 5.

Using fly revs at 2,600rpm in top gear on the motorway produced a maximum road speed of 93km / h (58mph), but the shallow gradients pulled this back to an average of 74km /h (46mph).

Brakes

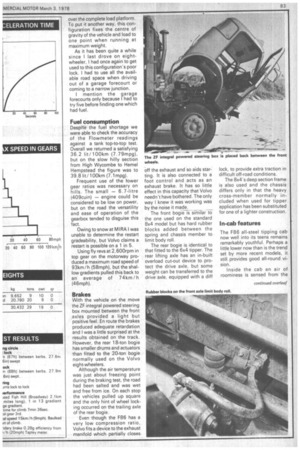

With the vehicle on the move the ZF integral powered steering box mounted between the front axles provided a light but positive feel. En route the brakes produced adequate retardation and I was a little surprised at the results obtained on the track. However, the rear 18-ton bogie has smaller drums and actuators than fitted to the 20-ton bogie normally used on the Volvo eight-wheelers.

Although the air temperature was just about freezing point during the braking test, the road had been salted and was wet and free from ice. On each stop the vehicles pulled up square and the only hint of wheel locking occurred on the trailing axle of the rear bogie.

Even though the F86 has a very low compression ratio, Volvo fits a device to the exhaust manifold which partially closes off the exhaust and so aids starting. It is also connected to a foot control and acts as an exhaust brake. It has so little effect in this capacity that Volvo needn't have bothered. The only way I knew it was working was by the noise it made.

The front bogie is Sim-Par-to the one used on the standard 8x4 model but has hard rubber blocks added between the spring and chassis member to limit body roll.

The rear bogie is identical to that fitted to the 6x4 tipper. The rear lifting axle has an in-built overload cut-out device to protect the drive axle, but some weight can be transferred to the drive axle, equipped with a diff lock, to provide extra traction in difficult off-road conditions.

The 8x4's deep section frame is also used and the chassis differs only in that the heavy cross-member normally included when used for tipper application has been substituted for one of a lighter construction.

In-cab features

The F86 all-steel tipping cab now well into its teens remains remarkably youthful. Perhaps a little lower now than is the trend set by more recent models, it still provides good all-round vision.

Inside the cab an air of roominess is sensed from the driving seat even though the cab is divided by a high carpeted engine cover.

Behind the seat there is sufficient room to stow extra ropes, sheets and so on. The driver's Bostrom suspension seat with adjustment for weight, squab position and back-rest angle is too easily taken for granted, but it effectively removes any high frequency shock loads transmitted being through the driver's seat. The result is a more comfortable and less wearing journey.

The cab tilts to 4O= allowing good access to the engine compartment but it is heavy for one man alone to work the release mechanism and lift at the same time. To keep within the UK C and U Regulations some small modifications have been made regarding the vehicle lights, both front and rear. The front grille has been cut away to accommodate twin headlamps mounted low down on the front panel.

Volvo's views

Although I considered the vehicle underpowered at 30 tons gross, many operators, I am told, are quite happy with the F86 in an articulated form operating at 32 tons gross. This must depend on the terrain in their operational areas.

1 told Volvo of my criticism of their engine airbrake; its defects are no new problem to them. As they say, with a relatively small engine best advantage will be obtained using it in conjunction with the gearbox. However, there are no plans to improve the engine's performance. With regard to the difficulty in raising the cab, various pump systems are being looked at, I'm told, and, although no one would say definitely, it looks as though we will have to wait for that to appear along with a restyled cab — whenever that may be.

The benefits of fitting an 18ton bogie enables the vehicle to attain a very low kerb weight allowing a payload comparable to those of many articulated vehicles in weight at least, if not in volume.

As rigids are not yet covered by the EEC 450 km restriction, this vehicle could provide an attractive alternative for some operators if only for a temporary period.

Other benefits are also claimed: they are improved fuel consumption and lower tyre wear when running empty with the axle lift in the raised position. This is mainly attributed to the reduction of the tyre scrubbing associated to the rear bogie.

Summary

Built with well tried cornponents, this Volvo should make a reliable vehicle to operate a if only for a short time, cc overcome the EEC, 450km Ii for those who can dispense v the versatility of an articula outfit.

The fuel consumption is gi for a vehicle running over route at 30 tons. Althoug would like to see a better lc the figures compare well vi those produced by other eic. wheelers. Priced at £19,920 the chassis-cab only it is a gc steady road-going vehicle wh should take occasional site vi in its stride,