Improvements in

Page 60

Page 61

Page 62

If you've noticed an error in this article please click here to report it so we can fix it.

Passenger vehicle

Seats

KABUS or coach seat should be comfortable, hard wearing light in weight. Furthermore, its design should be one which lends itself readily to repetition manufacture, because even a moderate-sized factory will require to produce many hundreds of seats in the course of a year's working.

At the present time wood is used more often than metal for the seat board or foundation of the cushion, whilst a wood frame, panelled with plywood, is the usual method of construction for the seat back.

The advantage of this kind of framework for the back of the seat is that it facilitates individual shaping anti the introduction of a distinctive outline for the top of the seat back. The attachment of the upholstery is also simplified by such construction.

But, In any case, suitable ,metal stays or brackets are .necessary in order to attach the back to the 42 cushion foundation, and the back itself is often reinforced with corner and other plates, especially if it be somewhat elaborately curved.

For the seat-legs metal is chiefly used, because it is inexpensive and light in weight, particularly when it takes the form of pressings. The metal support may also be compactly designed, it is easy to attach to the floor and it entails a minimum of labour for cleaning.

If metal is to be used for the cushion foundation, it may consist of a framework of metal angle, which, at the same time, forms a means for keeping the cushion in place. The cushion should be made up independently on a base of plywood, so that it may be easily removed at any time. If a metal seat back is to be produced by hand in comparatively small quantities, it should be of a design which entails a minimum of hand-beating, but if a standard pressing can be ' used individual shaping can be achieved with economy.

Metal tubing might also be employed for the seat framework. This material was some years ago used in a few instances for both private and public-service-vehicle bodywork. More recently its use was revived for the construction of an inexpensive saloon body, whilst to-day one is reminded of its merits, because the world's fastest car has a body of tubular construction. Apart from these considerations, the latest designs of chair and table for the home are made of tubes, So why not try this material for the bus or coach seat?

Tubing for Seat Supports.

The seat supports could consist of simple upright tubes with bottom flanges for attachment to the floor, or they could be bent at right angles at the bottom so that a base of tubing was formed. Attachment of the upholstery, or of any woodwork, could be effected by means of clips. Such a seat should be of minimum weight and it could have an untarnishable finish.

When designing the upholstery of a seat it is an advantage if it be made readily detachable. Such upholstery is easily cleaned, repaired Or replaced. The squab of the lea.r seat of a coach is usually attached to the inside of the body in such a -1,va7 that the upholstery or trimming has to be dismantled, if any repair be necessary to the back panel. An experienced coach trimmer is not always available in a garage when, without delay, such Work has to be undertaken during

the night. . •

. But if only a few screws have to be undone, then not only is the upholsterypreserved intact, but the repair job is carried out in less tine.

The easy detachment of the cushion—and back squab might also be utilized :to. ensure economy in another way. For aservice bus it is suggested that both cushion and back squab be made up with the

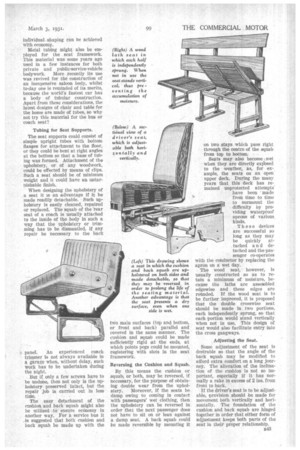

two main surfaces (top and bottom, or front and back) parallel and covered in the same manner. The cushion and squab could be made sufficiently rigid at the ends, at which points pegs could be mounted, registering with slots in the seat framework. • Reversing the Cushion and Squab.

By this means the cushion or squab, or both, may be reversed, if necessary, for the purpose of obtaining double wear from the uphol stery. Moreover, if the seats be damp owing to coming in contact with passengers' wet clothing, then the upholstery can be reversed in order that the next passenger does not have to sit on or lean against a damp seat. A back squab could be made reversible by mounting it on two stays which pass right through the centre of the squab from top to bottom.

Seats may also become -.wet • when they are directly exriosed to the weather, •its, for example, the seats on an open upper deck. During the many years that this deck has remained unprotected attempts' have been made from time to time to surmount the difficulty by providing waterproof aprons of various kinds.

These devices are successful so long as they may be quickly attached and detached and the passenger co-operates with the conductor by replacing the apron on a wet day.

The wood seat, however, is usually constructed so as to retain a minimum of moisture, because the laths are assembled edgewise and these edges are rounded. If the wood seat is to be further improved, it is proposed that the double crosswise seat should be made in two portions, each independently sprung, so that each portion would stand vertically when not in use. This design of seat would also facilitate entry into the cross gangways.

Adjusting the Seat.

Some adjustment of the seat is desirable so that the angle of the back squab may be modified to afford extra comfort on a long journey. The alteration of the inclination of the cushion is not so important, especially if it has normally a rake in excess of 2 ins, from front to back.

If the driver's seat is to be adjustable, provision should be made for movement both vertically and horizontally. The foundation of the cushion and back squab are hinged together in order that either form of adjustment keeps both parts of the seat in their proper relationship. Having decided upon the general design of the seat, there are countless ways in which it may be made attractive by the selection of suitable patterns and colours of uphol stery. Leather and leather-cloth are available in various grains, whilst the moquette manufacturer has all the resources of the loom at his disposal. In the near future prob

ably more will he seen of modernistic patterns than at preseat ; these will replace some of the rather conventional floral displays now seen in some quarters.

For the bus or coach seat leather and moquette. are often used in combination, the former material being employed for the borders of the cushion and the ends of the back

FAruali. By this means friction between the passengers' clothing and the seat-covering material is reduced to a minimum and the variety of texture and colouring thus introduced enhances the artistic effect of the interior display.

It is advisable to limit the vertical mbvement of the seat springs to minimize wear on the upholstery.