An Hydraulic Remote-control System

Page 33

If you've noticed an error in this article please click here to report it so we can fix it.

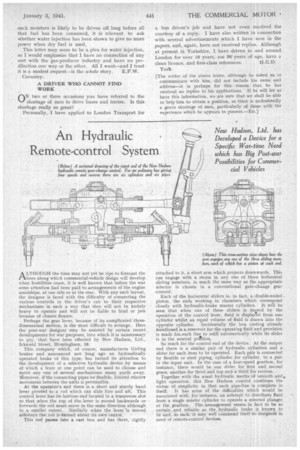

New Hudson, Ltd. has Developed a Device for a Specific Wartime Need which has Big Post-war Possibilities for Commer cial Vehicles

ALTHOUGH the time may not yet be ripe to forecast the lines along which commercial-vehicle design will develop when hostilities cease, it is well known that before the war some attention had been paid to arrangements of the engine amidships, at one side or at the rear. With any such layout, the designer is faced with the difficulty of connecting the various controls in the driver's cab to their respective. mechanisms in such a way that they will not be unduly heavy to operate and will not be liable to bind or jam because of chassis flexure.

Perhaps the gear lever, because of its complicated threedimensional motion, is the most difficult to arrange. Here the post-war designer may be assisted by certain recent . developments for war purposes, into which it is unnecessary to pry, that have .been effected by New Hudson, Ltd., Icknield Street, Birmingham, 18.

This company which, of course, manufactures Girling brakes and announced not long ago an hydraulically operated brake of this type, has turned its attention to the development of a selective hydraulic device by means of which a leyer at one point can be used to choose and move any one of several mechanisms many yards away. Moreover, if-the connecting pipes be flexible, limited relative movement between the units is permissible.

At the operator's end there is a short and sturdy hand lever pivoted to a rod which can slide fore and alt. This control lever has its bottom end located in a transverse slot so that when the top of the lever is moved backwards or forwards the rod must move in the same direction although to a smaller extent. Similarly when the lever 'is moved sideways the rod is turned about its own centre.

This rod passes into a cast box and has there, rigidly

attached to it, a short arm which projects downwards. This can engage with a, recess in, any one of three horizontal sliding members, in much the same way as the appropriate selector is chosen in a conventional gate-change gear • control.

Each of the horizontal sliders is, in fact, a double-ended piston, the ends working in chambers which correspond closely with hydraulic-brake master cylinders. It will be seen that when one of these sliders is moved by the operation of the control lever, fluid is displaced from one cylinder whilst an equal volume of fluid is drawn into the opposite cylinder. Incidentally the box casting already mentioned is a reservoir for the operating fluid and provision is made for,, each line to refill automatically while its slider is in the neutral poltion.

So much for the control end of the device. At the output end there is a similar pair of hydraulic cylinders and a slider for each item to be operated. Each pair is connected by flexible or steel piping, cylinder, for cylinder, to a pair in the input unit. In the case of a four-speed gearbox, for instance, there would be one slider for first and second gears, another for third and top and a third for reverse. Together with the usual hydraulic merits of smooth and, light operation, this New Hudson control combines the virtue of simplicity in that each pipe-line is complete in itself. It has none of the difficulties which would be associated with, for instance, an attempt to distribute fluid from a single master cylinder to operate a selected pillager at the gearbox. The arrangement seems in fact to be as certain and reliable as the hydraulic brake is known to be and, as such, it may well commend itself to designers in need of remote-control devices.