Cummins E290

Page 41

Page 42

Page 43

Page 44

If you've noticed an error in this article please click here to report it so we can fix it.

comes on strong

brew engine from Shotts is quieter, cleaner and less thirsty....

by the Technical Editor

ENGINES are supplied by Cummins to ERF, Fodens, Ford, Leyland and Seddon Atkinson and Bedford is now to be added. Thus any new engine from the company is an important factor for a lot of people, manufacturers and operators alike, so today's announcement of the Formula E290 is a significant event in the transport calendar.

The existence of the "Big Cam" engine has been a fairly' open secret for some time now (see CM July 15 last year) although the details have been somewhat sketchy. One of the first things that Cummins have done with the production engine is to alter the name from "Big Cam" to the official Formula E290 although I still think that most people will still use the' former identification.

The new unit is based on the familiar 14-litre (854cuin) sixcylinder Cummins which retains the familiar injection system, but there the similarity ends. The maximum power of the Formula E290 is 216kW (290bhp) gross to BS AU 141a with a corresponding maximum torque figure of 1,260Nm (930Ibft) at 1,30Orpm.

Two lower power ratings are also available (on request from the chassis manufacturers) with both governed at the same speed. The, moderately derated. version develops 201 kW (270bhp) with no loss of torque while the most conservatively rated one produces 190kW (255bhp) with 1,150Nm (850Ibft) of torque. This last rating is for applications where the gearbox or axle torque capacity is limited.

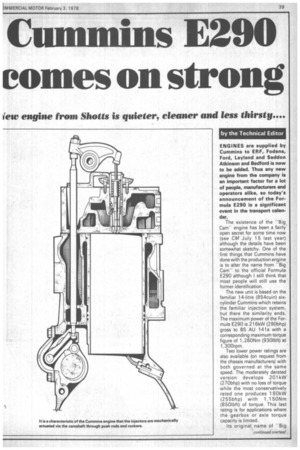

Its original name of "Big Cam" Was derived from the fact that the diameter of the camshaft has been increased from 51 to 64mm (2 to 2.5in).

The Cummins engine family operates on a different injection system to most heavy diesel engines in that the injectors are mechanically actuated — via push rods and rockers — from the engine camshaft. The feed lines from the pump to the injectors are thus operating at a much lower pressure than normal.

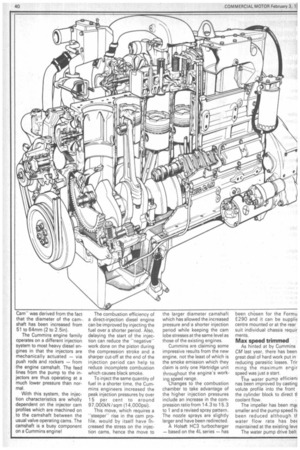

With this system, the injection characteristics are wholly dependent on the injector cam profiles which are machined on to the camshaft between the usual valve operating cams. The camshaft is a busy component on a Cummins engine! The combustion efficiency of a direct-injection diesel engine can be improved by injecting the fuel over a shorter period. Also, delaying the start of the injection can reduce the "negative" work done on the piston during the compression stroke and a sharper cut-off at the end of the injection period can help to reduce incomplete combustion which causes black smoke.

To inject the same quantity of fuel in a shorter time, the Cummins engineers increased the peak injection pressures by over 15 per cent to around 97,000kN /sqm (14,000psi).

This move, which requires a "steeper" rise in the cam profile, would by itself have increased the stress on the injection cams, hence the move to the larger diameter camshaft which has allowed the increased pressure and a shorter injection period while keeping the cam lobe stresses at the same level as those of the existing engines.

Cummins are claiming some impressive results from the new engine, not the least of which is the smoke emission which they claim is only one Hartridge unit throughout the engine's working speed range. Changes to the combustion chamber to take advantage of the higher injection pressures include an increase in the compression ratio from 14.3 to 15.3 to 1 and a revised spray pattern. The nozzle sprays are slightly larger and have been redirected. A Holsect HC3 turbocharger — based on the 4L series — has been chOsen for the Formu E290 and it can be suppliE centre mounted or at the rear suit individual chassis requir ments.

Max speed trimmed

As hinted at by Cummins CM last year, there has been great deal of hard work put in reducing parasitic losses. Trir ming the maximum ergir speed was just a start.

The water pump efficieni nas been improved by casting volute profile into the front the cylinder block to direct ti coolant flow.

The impeller has been me4 smaller and the pump speed h been reduced although tF water flow rate has beE maintained at the existing levE The water pump drive belt single wide multi-vee belt of e type already used on Cumins engines fitted to the Ford anscontinental. Cummins esnate that a saving of around 5 horsepower has been made the water pump assembly one.

This process of reducing the irasitic losses has been exnded to the oil pump as well. A J dy has shown that a reducin in the pressure and capacity the pump was possible with ) loss in lubrication efficiency th the result that the Formula ?90 oil pump absorbs only 2.5 fsepower (maximum).

Still on the lubrication side, a designed oil filter/cooler sembly has been incorporated smplete with thermostat. This lows the cooler to be by passed until a working temperature of about 105' C (220 F) has been reached which ensures an optimum viscosity level which in turn reduces churning losses and viscous drag under light-load operating conditions.

In the piston area, oil is now fed to each gudgeon pin via an offset drilling down one side of the connecting rod while, at the big end, cap-screws and threaded bosses are employed in place of fitted bolts and nuts.

As a redesign of the cylinder block was necessary to get the larger camshaft in, stiffening ribs were cast into the block wall at the same time to reduce vibration and noise.

Axle change

The Formula E290 has caused the chassis manufacturers some headaches as in most cases a change in rear axle specification has been necessary.

Seddon Atkinson, for example, will offer an Eaton axle on the short term and a Rockwell single-reduction axle on the long term in place of the current -grouphub reduction axle. Work is currently proceeding at Seddon Atkinson tci produce a higher ratio for their own axle which is the hold-up to its use" with the Cummins.

Ending months of speculation, Bedford has finally announced that the new Cummins will be listed as an option to the two-stroke Detroit Diesel 8V-71 unit fitted to the TM 3800.

Again an axle change will be necessary from the French-built SOMA to Rockwell who would seem to be doing very nicely thank you courtesy of Cummins.

Driver education

Cummins have stressed the need for driver education with the new engine if its maximum potential is to be utilised.

Perhaps -driver educationis too strong an expression and "driver familiarisation"' is a better one as, although an existing Cummins driver will need to repdjust his technique, a Gardner driver will have no trouble.

The best cruising speed range, according to Cummins, is between 1,200 and 1,700rpm with the working speed range given as between 1,000 and 1,900rpm. The reduction in speed from 2,100 or even 1950, has been carried out to reduce the parasitic losses within the engine.

One problem, if I can call it that, is that the Formula E290 is a very free-revving engine. When I first took over the whe of a Seddon Atkinson fitted wi the new Cummins, I found th it was very easy indeed to be t to 2,000rpm before I realise The rev counter on the 4C series was red-lined 2,100rpm, which is a sa speed as far as the mechanic units are concerned — it ju doesn't do a lot for tt economy.

To illustrate the effect "driving to the book" opposed to revving up to the n line, I carried out a back-to-ba, test over a 125km (78-mile) 1E route. On the first run I chang up at around 2,000rpm an when a gradient came up, changed down at 1,300rpm.

On the second run arout the same course on the sar day to try and equate weathe traffic conditions, I kept to tl Cummins recommendations changing up at 1,600,rpm at down — when the conditio allowed it — at arour 1,00Orpm.

This latter figure was ye much dependent on the ra conditions. For example, if t engine speed was faith towards the 1,000rpm ma and the end of the gradient w in sight then it was perfecacceptable.

If, however, the gradient w going to go on for a long tir then-it was advisable to chan down at around 1,200rpm keep the engine in its be cruising range.

The test route comprised sorts of road conditions i eluding hilly sections and a sf tion of Ml. Starting off from t Cummins service department Wellingborough. I took t Seddon Atkinson over a stret of winding road followed by constant speed run on the sot. bound Al. I then cut acre towards Bedford and joined N for the run back to the N( thampton turn off and Wellir borough.

Fuel consumption

The difference in fuel cc sumption was dramatic. Taki the first test when I used up 2,000rpm, the fuel consurr tion worked out at 44 lit/100km (6.4mpg) for t 125km (78 miles). Reverting the -let it lug" technique, t consumption improved to 3E lit/100km (7.3mpg). There sit very little difference in the jo ney time whichever driving st was used -some five minu. in two hourq