HOW PLATING WILL AFFECT THE TIPPER OPERATOR

Page 96

If you've noticed an error in this article please click here to report it so we can fix it.

IT'S all very interesting, but it doesn't affect me." This reaction to the new braking and plating regulations is still surprisingly common, but in many cases will prove mistaken.

How will the changes in regulations affect operators? First, certain trends will strengthen. For example, more owners will try to achieve maximum payload by reducing kerb weights in any way that won't affect reliability. There are already indications that many operators are considering light alloy bodywork and equipment. Much development work has been done in recent years in this field, and I think we shall see a substantial increase in the use of this type of bodywork.

The full effects of the new legislation will be wider. Consider a small fleet owner now running ten 10 ft.-wheelbase forward-control tippers fitted with 6 cu. yd. steel bodies and with a manufacturer's gross rating of 11.2 tons (25,000 lb.), popularly known as if tanners.

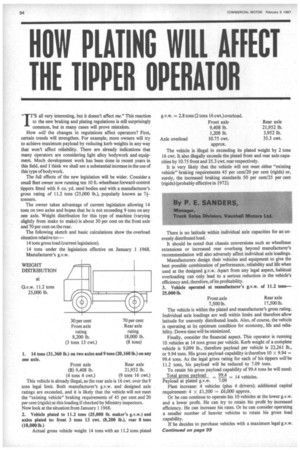

The owner takes advantage of current legislation allowing 14 tons on two axles and hopes that he is not exceeding 9 tons on any one axle. Weight distribution for this type of machine (varying slightly from make to make) is about 30 per cent on the front axle and 70 per cent on the rear.

The following sketch and basic calculations show the overload situation relative to: 14 tons gross load (current legislation).

14 tons under the legislation effective on January 1 1968. Manufacturer's g.v.w.

This vehicle is already illegal, as the rear axle is 16 cwt. over the 9 tons legal limit. Both manufacturer's g.v.w. and designed axle ratings are exceeded, and it is likely that the vehicle will not meet the "existing vehicle" braking requirements of 45 per cent and 20 per cent (rigids) at this loading if checked by Ministry inspectors. Now look at the situation from January 11968.

2. Vehicle plated to 11.2 tons (25,000 lb. maker's g.v.w.) and axles plated to: front 3 tons 13 cwt. (8,200 113.), rear 8 tons (18,000 lb.) Actual gross vehicle weight 14 tons with an 11.2 tons plated The vehicle is illegal in exceeding its plated weight by 2 tons 16 cwt. It also illegally exceeds the plated front and rear axle capacities by 10.75 front and 35.3 cwt. rear respectively.

It is very likely that the vehicle will not meet either "existing vehicle" braking requirements 45 per cent/20 per cent (rigids) or, surely, the increased braking standards 50 per cent/25 per cent (rigids) (probably effective in 1972).

There is no latitude within individual axle capacities for an unevenly distributed load.

It should be noted that chassis conversions such as wheelbase extensions or increased rear overhang beyond manufacturer's recommendation will also adversely affect individual axle loadings.

Manufacturers design their vehicles and equipment to give the best possible combination of performance, reliability and life when used at the designed g.v.w. Apart from any legal aspect, habitual overloading can only lead to a serious reduction in the vehicle's efficiency and, therefore, of its profitability.

3. Vehicle operated at manufacturer's g.v.w. of 11.2 tons25,000 lb.

Front axle Rear axle 7,5001b. 17,500 lb.

The vehicle is within the plated and manufacturer's gross rating. Individual axle loadings are well within limits and therefore allow latitude for unevenly distributed loads. Also, of course, the vehicle is operating at its optimum condition for economy, life and reliability. Down-time will be minimized.

Finally, consider the financial aspect. This operator is running 10 vehicles at 14 tons gross per vehicle. Kerb weight of a complete vehicle is 9,099 lb.. therefore payload per vehicle is 22,261 lb., or 9.94 tons. His gross payload capability is therefore 10 x 9.94 -99.4 tons. As the legal grass rating for each of his tippers will be 11.2 tons, his payload will be reduced to 7.09 tons.

To retain his gross payload capability of 99.4 tons he will need: Total gross payload = 99.4 = 14 vehicles.

Payload at plated g.v.w. 7.09 Fleet increase: 4 vehicles (plus 4 drivers); additional capital requirement: 4 X £1,500 — £6.000 approx.

Or he can continue to operate his 10 vehicles at the lower g.v.w. and a lower profit. He can try to retain his profit by increased efficiency. He can increase his rates. Or he can consider operating a smaller number of heavier vehicles to retain his gross load capability.

If he decides to purchase vehicles with a maximum legal g.v.w. Continued on page 99