A Review of DIESEL-ENGINE PROGRESS

Page 54

Page 55

Page 56

If you've noticed an error in this article please click here to report it so we can fix it.

A Precis of a Paper Read Last Week. Interesting Data and a Consideration of Future Possibilities d'A NE of the most striking features a IL/the commercial-vehicle industry of the present time is the great attention which is being paid to the possibilities of the compression-ignition engine. From time to time we have published in The Commercial Motor news of developments and descriptions of various designs. Below we give some interesting details extracted from a paper read by Mr. S. W. Nixon. M.Sc., before the Luton graduates of the Institution of Automobile Engineers, on Thursday last, November 28th.

The subject is dealt with in the paper under the following headings :-(1) Notes on the compression-ignition cycle. (2) Tabulation and discussion of the advantages of the cycle. (3) Comparison of the compression-ignition and carburetter-type engines. (4) Methods of injection and requirements in connection therewith. (5) Details of certain existing engines. (6) An outline of future possibilities.

The Required Engine Speed.

Mr. Nixon expresses the opinion that, to compete reasonably with the petrol engine, the compression-ignition unit must operate at speeds in the neighbourhood of 1,500 r.p.m. in order to obtain engines of a suitable powerto-weight ratio and to give even torque.

On the question of desirable maximum pressure and its effect on structural weight there is a wide divergence of opinion. Certain parties hold that it is not economical to inject more than

B28 25 per cent. to 30 per cent. of the fuel at constant volume, but the Packard compression-ignition aeroplane engine operates on a true. constant-volume cycle with a compression ratio of about 18 to 1, has to withstand pressures in excess of 1,200 lb. per sq. in. and has a weight of only about 3 lb. per b.h.p. On the Continent certain Diesel engines are running with very high compression ratios, and have a weight-to-power ratio of 15 lb. to 25 lb. per b.h.p.

In the portion of the paper dealing with the advantages of the compressionignition engine, the following are set forward as its merits :—(e) The utilization of cheap fuel of high flash-point; (b) the specific fuel consumption is reduced; (c) electric ignition is eliminated; (d) the carburetter and induction system are • replaced by a simple individual pressure feed to each cylinder.

In regard to the first point, engines of this type have actually been operated on a mixture of waste paraffin from washing tanks, waste lubricating oil and oil recovered from sewage. As regards the fuel-consumption question, it is pointed out that the difference between the Diesel and the petrol engine is more marked at reduced speeds, the flat consumption curve being a result of the method of controL

The Peugeot-Junkers engine shows only 5 per cent. variation in fuel consumption when running at 29 b.h.p. or 50 b.h.p. The difference in the case of the .petrol engine would be in the neighbourhood of 30 per cent.

Amongst the miscellaneous advantages of the compression-ignition power producer are the fact that it can be handled equally well by skilled or unskilled persons, gear-changing is less frequently required owing to the good torque at low speeds, the exhaust is more easily silenced owing to the low temperature of the used gases when discharged and the Diesel engine can work in a wider range of temperatures than a petrol engine. Supercharging is easily arranged, as it is only necessary to deal with the air supply.

Where Development is Needed.

The disadvantages, as set forth. by Mr. Nixon; are :—(a) Weight per hp. is high ; (b) mean effective pressure and' power output ..per unit of cylinder , volume are comparatively low ; (e) the difficulties involved in accurately metering small quantities of fuel at high pressure ; (d) . the need for special. means for ensuring good starting from cold.

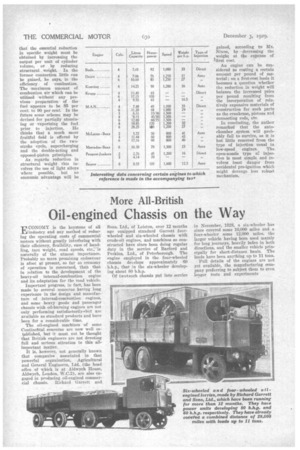

It would appear that, in the present standard of design, the heavy-oil engine for commercial service must be some 20 per cent, heavier than its petrol counterpart. An interesting set of figures is included in a table reproduced in part in these pages. In a modern petrol engine roughly 100 B.Th.U.s are present per -cubic ft. of mixture, 22.4 per cent. of which is converted into useful work ; in the case of the compression-ignition engine there are 40,

B.Th.U.s available and 30.5 per cent, is converted into useful work.

The difficulty experienced in metering the fuel quantities cannot be regarded as serious, judging by the figures advanced by Mr. Nixon. The M.A.N. pump is capable of injecting 90 cubic mm. per stroke per cylinder, or a drop 2.8 mm. in diameter. The Deutz pump is adjusted so that the variation between maximum and minimum delivery is less than 5 per cent. of that when the engine is idling. The well-known Bosch pump has metered .75 cubic mm. of oil per injection at 2,000 r.p.m., with a variation of about 1 per cent., whilst It is claimed that the Austrian Frey motorcycle engine develops 6. b.h.p. at 2,400 r.p.m., tbe fuel injected per stroke being either 25 cubic mm., or a drop 1.8 mm. in diameter.

Regarding methods of injection, the author outlines in his paper the three 'principles :—(a) Air. injection ; (b) injection into an antechamber or precombustion chamber; (c) direct

The first type is adopted OIL the Maybach engine, but, according to Mr. Nixon, is not really suitable for the light type of engine required for road duty. The fuel is blown into the combustion chamber at a pressure of about 750 lb. per sq. in. The antechamber system, as will be seen in the table reproduced, is adopted by about 50 per cent. of the well-known makers. The usual fuel pressure employed is between 900 lb. and 1,500 lb. per sq. in.

In the case of direct-injection systems the fuel pressures are up 10 4,500 lb. per sq. in. Reference is made to the rotational-swirl system developed

by Ricardo, for which the following advantages are advanced :—(a) Reduced fuel pressures are required; (1)) rapid and clean combustion results from good atomization and distribution ;

fixed ignition can be adopted due to the fact that the swirl varies as the piston speed ; (d) the compact combustion space is conducive to reasonable ease of cold starting.

Mr. Nixon, in his paper, refers to engines of many makes, and outlines their specifications and general principles. Summarizing the designs he says that manufacturers tend to standardize cylinder dimensions, the various powers required being obtained by altering the number of cylinders. In general, petrol. engine practice is largely followed as regards crankcase and cylinder construction, but only one maker takes advan; tage of the two-stroke cycle. Most of the larger designs have the top half of the crankcase and cylinder casting as a unit, the barrels being pressed in. All the engines have pressure lubrication and in some cases it extends to the gudgeon pins. The engines referred to are of the following makes :—Deutz, Koerting, Krupp, M.A.N., Buda, ,,McLaren Benz, Peugeot Junkers, Saurer and Frey; also aero engines of Packard, Century (rotary), Junkers, Sunbeam and Beardmore manufacture.

Turning to the question of future possibilities, Mr. Nixon is of the opinion that the essential reduction in specific weight must be obtained by increasing the output per unit of cylinder volume, or by reducing structural weight. In the former connection little can be gained, he says, in the efficiency of combustion. The maximum amount of combustion air which can be utilized without any previous preparation of the fuel appears _to be 85 per cent. to 90 per cent. In the future some scheme may be devised for partially atomizing or vaporizing the fuel prior to injection. He thinks that a much more fruitful field is offered by the adoption of the twostroke cycle, supercharging and the double-acting and opposed-piston principles.

As regards reduction in structural weight this involves the use of light alloys where possible, but no economic advantage will be gained, according to Mr.

Typed Nixon, by .decreasing the Injection weight at the expense of

'1first cost.

Au engine can be considered as costing a certain amount per pound of material; on a first-mist basis it becomes a question whether

Ante the reduction in weight will Dirac t balance the increased price

per pound resulting from the incorporation of rela

Direct tively expensive materials of construction for such parts as the crankcase, pistons and connecting rods, etc.

In concluding, the author remarked that the antechamber system will probably fail to survive, as it is but little removed from the type of injection usual in low-speed engines. The open-nozzle type or injection is most simple and in

Ante volves least danger from accidental pre-ignition which might derange less robust mechanism.