SIMPLIFYING REPAIR AND MAINTENANCE.

Page 11

If you've noticed an error in this article please click here to report it so we can fix it.

Little Points of Design that are of Importance, but which are so Frequently Neglected.

WHILST not wishing to make any criticisms concerning the design of the main components of a commercial motor, I put forward the following suggestions as being of importance to fleet engineers and those who have to disassemble and reassemble all kinds of motors.

It is possible that the small details with which I am dealing are so small that they have escaped the notice of designers, but I feel that if those designers were condemned as a punishment to maintain and repair the vehicles they design they would give more attention to such small matters.

A London magistrate, who was renowned for his wit, once had a case before him where a driver was summoned for allowing smoke and fumes to be discharged from his exhaust pipe. The magistrate said : "Where is that pipe situated?" and on being told that it was at the rear of the vehicle, he said : "I thought so; had that pipe been situated under your nose you would take good care that no fumes came from it." I feel that the same principle applies to the small details of construction.

The Split Pin that Cannot be Opened.

To begin with one of the smallest yet one of the most vexing points—those who make split pins have, for years. taken the greatest care that both ends of the pin should be of exactly the same length. This makes the opening of thelpin a very difficult operation where it is not easy to get a screwdriver between the points and is the cause of much profanity. Split pins are now procurable made with common sense, namely, with one point longer than the other, So that they can be spread with ease. Why are they not generally adopted?

All bolts and screwed parts could be made with a plain part, as shown in a sketch accompanying this comment. The plain part would allow of a certain amount of driving in obstinate cases without burring the ends. In the case of bolts, this could be done in the operation' of parting the bolt from the stock from which it is made, and would not only prevent burring but would help in assembling in eases where the operator cannot see the nut as it is put on its bolt. This would save much fumbling and cross-threading.

The B.S.F. Thread Better than the Whitworth Thread.

Could not British standard fine thread be used throughout the whole trade and the nnsuitable Whitworth pitch be abandoned for ever for motor work? This would simplify stockkeeping, both for the manufacturer and the repairer. Not only is the B.S.F. thread stronger than the Whitworth, but it is less likely to work loose, owing to the fact that the wedge formed by the helix is of a more acute angle. With a B.S.F. bolt of high-tension steel and a genuine Grover washer, well tightened up, there is little need for split pins or other contrivances to keep bolts from coming loose. With regard to the diameter of heads of bolts and nuts, there is little doubt that the standard size as set down by Whitworth is best for such parts as the brackets that are bolted to the frames and wing stays, but for other parts the smaller heads and nuts are neater.

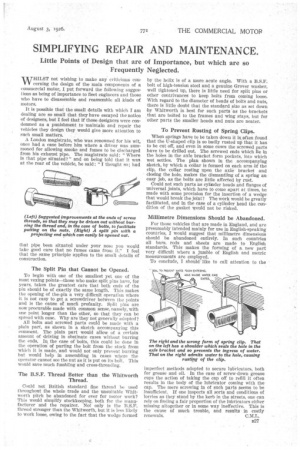

To Prevent Rusting of Spring Clips.

When springs have to be taken down it is often found that the U-shaped clip is so badly rusted up that it has to be cut off, and even in some cases the screwed parts have to be drilled out. The screwed ends which lie in the holes in the axle bracket form pockets, into which wet settles. The plan shown in the accompanying sketch, by which a collar is formed on each arm of the clip, the collar resting upon the axle bracket and closing the hole, makes the dismantling of a spring an easy job, as the bolts are little affected by rust.

Could not such parts as cylilader heads and flanges of universal joints, which have to come apart at times, be made with some provision for the insertion of a wedge that would break the joint? The work would be greatly facilitated, and in the case of a cylinder head the condition of the gasket would not be risked.

Millimetre Dimensions Should be Abandoned.

For those vehicles that are made in England, and are presumably intended mainly for use in English-speaking countries, I would suggest that millimetre dimension's should be abandoned entirely. In such countries all bars, rods and sheets are made to English standards. This makes the forming of a new part very difficult where a jumble of English and metric measurements are employed.

To conclude, I should-like to call attention to the

imperfect methods adopted to secure lubricators, both for grease and oil. In the case of screw-down grease cups the action of taking the cap off to refill it often results in the body of the lubricator coming with the cap. The mere screwing in of such parts seems to be insufficient. If one inspects all sorts and conditions of lorries as they stand by the kerb in the streets, one can rely on finding a fair proportion of the lubricators either missing altogether or in some way ineffective. This is the cause of much trouble, and results in costly renewals.