VEHICLE TESTING

Page 61

Page 62

If you've noticed an error in this article please click here to report it so we can fix it.

DTp INSPECTION

TESTING TIM

A West London testing station gives some insights into why vehicles fail the annual test. Karen Miles reports I Companies may )end up to four days 7eparing their vehicles T annual test, but, pressingly, around 20 cent of all HGVs and SVs still fail, national ;tires show.

Vehicles tend to pass [e bodywork and iassis inspection with 1ative ease; it is the -ake test that will often ilt progress.

Every year around 000 HGVs are ,sted. Overall 22% fail, do 20% of the 64,000 SVs tested.

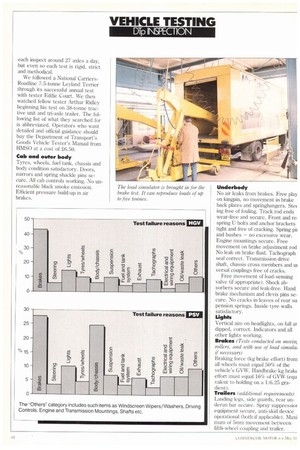

The graph overleaf lows that for HGVs, over 40% of e total test failures are brought out by poor brakes. The second use of failures, unsatisfactory lights, ails far behind at around 13%. For PSVs, brakes cause around 7% of all failures. Following close [hind, at around 25% of failures and !fleeting the added stringency in 'sting of PSV bodies. are body and iassis faults.

Vehicle Inspectorate staff blame the high failure with brakes on braking sophistication. District manager for West London's Yeading testing station John White explained: "The more sophisticated design of brakes today present problems for many operators. They don't understand them so easily, and so there's more chance of an oversight in maintenance."

White says that vehicles which are worked arduously, and especially on _rough roads, are more • likely to fail. They need most maintenance, and problems are more likely to be missed.

When CM watched Yeading Vehicle Inspectorate staff going through the annual test, three factors became clear.

First, a driver with a screwdriver, who can quickly fix simple faults the tester spots, is an asset. A "Pass after Rectification" is much cheaper. It saves the operator paying out 212 for a vehicle re-test on top of the 223.50 for the initial test and another 27 for the trailer. (For PSVs with 13 or more seats the first test costs 233, the retest 216.50. PSVs with nine to 12 seats are charged 223 for the first test and 211.50 for the re-test.) Second it became obvious that vehicles are simply turned away if they are too dirty to inspect — and that includes tyres.

Third, Yeading testers, at least, each inspect around 27 axles a day, but even so each test is rigid, strict and methodical.

We followed a National CarriersRoadline 7.5-tonne Leyland Terrier through its successful annual test with tester Eddie Court. We then watched fellow tester Arthur Ridley beginning his test on 38-tonne tractive unit and tri-axle trailer. The following list of what they searched for is abbreviated. Operators who want detailed and official guidance should buy the Department of Transport's Goods Vehicle Tester's Manual from HMS() at a cost of £6.50.

Cab and outer body

Tyres, wheels, fuel tank, chassis and body condition satisfactory. Doors, mirrors and spring shackle pins secure. All cab controls working. No unreasonable black smoke emission. Efficient pressure build-up in air brakes. Underbody No air leaks from brakes. Free play on kingpin, no movement in brake back plates and springhangers. Ste( ing free of fouling. Track rod ends wear-free and secure. Front and re. spring U bolts and anchor brackets tight and free of cracking. Spring pii and bushes no excessive wear. Engine mountings secure. Free movement on brake adjustment rod No leak on brake fluid. Tachograph seal correct. Transmission drive shaft, chassis cross members and ui versal couplings free of cracks.

Free movement of load-sensing valve (if appropriate). Shock absorbers secure and leak-free. Hand brake mechanism and clevis pins secure. No cracks in leaves of rear su pension springs. Inside tyre walls satisfactory.

Lights

Vertical aim on headlights, on full ar dipped, correct. Indicators and all other lights working.

Brakes (Tests conducted on movin, rollers, and with use of load simulai necessaiy) Braking force (kg brake effort) from all wheels must equal 50% of the vehicle's GVW. Handbrake kg bralq effort must equal 16% of GVW (equ valent to holding on a 1:6.25 gradient ).

Trailers (additional requirements) ',raiding legs, side guards, rear underun bar secure. Spray suppressiot equipment secure, anti-skid device operational (both if applicable). Maxi mum of 5mm movement between fifth-wheel coupling and trailer.