A NEWCOMER TO UNDERTYPE STEAM WAGONS.

Page 52

Page 53

If you've noticed an error in this article please click here to report it so we can fix it.

A Full Description of the New Product of the Foden Works, Now Out of its Experimental Stage.

/TIRE past eight years have seen very .1 great technical and mechanical developments in the steam wagon. No doubt the fundamental changes which have been made in steam-wagon design since the war would have been commenced earlier but for the inevitable suspension, brought about by the period of hostilities, of,all attempts to introduce needed improvements. Motorcar engineering production, working to extremely fine limits, has laid down a new standard in design and method of engineering construction, and these standards are now being extensively adopted in other classes of work outside the factories manufacturing petrol vehicles.

The steam-wagon manufacturer has had the incentive of the conipetition of the petrol vehicle, and he has also had the benefit of improvements in machine tools, and the result is that more developments have taken place in steamwagon design during the past eight years than in the 20 years that compassed the history of the comparatively modern type of steam vehicle.

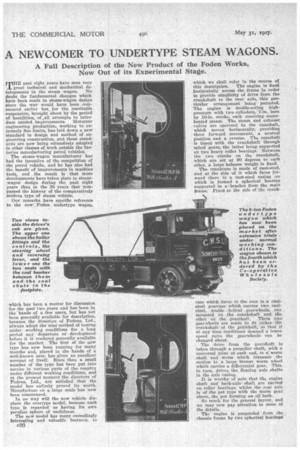

Our remarks have specific reference to the new. Foden undertypa wagon, which has been a matter for discussion for the past two years and has been in the hands of a few users, but has not been generally available for description, because the directors of Fodens, Ltd., always adopt the wise method of testing under working conditions for a long period any departure or development before it is rendered generally available for the market. The first of the new type has now been running for many months and, placed in the hands of a well-known user, has given an excellent account of itself. Since then a small number of the type has been put into service in svarious parts of the country under different working conditions, and at the present moment the directors of Fodens, Ltd., are satisfied that the model has entirely proved its worth. Manufacture on a large scale has now been ccimmenced.

In no way will the new vehicle displace the overtype model, because each type is regarded as having its own peculiar sphere of usefulness.

The new model has many exceedingly interesting and valuable features, to which we shall refer in the course of

this description. The engine is fixed horizontally across the frame in order to provide simplicity of drive from the crankshaft to the rear axle, this particular arrangement being patented. The engine is double-acting highpressure with two cylinders, 7-in, bore by 10-in, stroke, each receiving superheated steam. The steam and exhaust valves are operated by the camshaft, which moves horizontally, providing three forward movements, a neutral position and a reverse. The camshaft is timed with the crankshaft through spiral gears, the latter being supported on two heavy roller bearings. Between the two cranks on the crankshaft, which are set at 90 degrees to each other, a large balance weight is fixed.

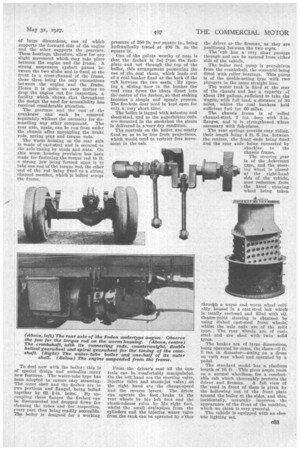

The crankcase is made of cast-steel, and at the side of it which faces forward there is a cast-steel casing on which is formed a spherical bearing supported in abracket from the main frame. Fixed to the side of the crank case which faces to the rear is .a caststeel gearease which carries two caststeel, double helical gearwheels, one mounted on the crankshaft and the other on the gearshaft.. These two gearwheels are made to fit either the crankshaft or the gearshaft, 4o that if at any time conditions demand a lower speed ratio the gearwheels can be changed about.

The drive from the gearshaft is taken through a propeller shaft, with a universal joint at each end, to a worm shaft and worm which transmit the motion to a large bronze worm wheel -which carries a differential gear. This, in turn, drives the floating axle shafts in the axle casing.

It is worthy of note that the engine shaft and back-axle." shaft are carried on roller bearings, whilst the rear axle is of the pot type with the worm gear above, the pot forming an oil bath.

So much for the general layout, and we may now pay attention to some of the details.

The engine is suspended from the chassis frame by two spherical bearings of large dimensions, one of which supports the forward side of the engine and the other supports the gearcaee. These bearings, therefore, allow for any slight movement which may take place between the engine and the frame. A strong suspension eyebolt passes between the two slides and is fixed at the front to a cross-channel of the frame, these three being the only connections between the engine and the frame. Hence it is quite an easy matter to drop the engine out for inspection, a facility which shows that throughout the design the need for accessibility has received considerable attention.

The gearcase and the end of the crankcase can each he removed separately without the necessity for dismantling any other component. The rear axle, again, can be run from under the chassis after uncoupling the brake rods, spring pins and torque rods.

The worm housing on the rear axle is made of cast-steel and is secured to the axle casing by studs and nuts. On this worm housing provision has been made for fastening the torque rod to it, a strong jaw being formed upon it to take one end of the torque rod, the other end of the rod being fixed to a strong channel member, which is bolted across the frame.

To deal now with the boiler ; this is of special design and embodies many new features. The water-tube type has been adopted to ensure easy steaming. The outer shell and the firebox are in two portions and flanged, being bolted

together by 62 I-in. bolts. By uncoupling these flanges the firebox can be disconnected and dropped down for cleaning the tubes and for inspection, every part then being readily accessible. The boiler is designed for a working

pressure of 250 lb. per square in., being hydraulically tested at 400 lb. to the square in.

One of the points worthy of note is that the firebox is fed from the footplate and not through the top of the boiler, this arrangement permitting the use of the coal chute, which leads out of a coal bunker fixed at the back of the cab between the two seats. By opening a sliding door in the bunker the cold runs down the Chute direct into the centre of the firebox, so that stoking becomes a simple and speedy process. The fire-hole door need be kept open for only a very short time. The boiler is lagged with asbestos and sheet-steel, and as the superheater coils are mounted in the smakebox the steam is delivered in a very dry condition. The controls on the boiler, are neatly fixed so as to be free from projections, which would, tend to restrict free movement in the cab.

From the driver's seat all the controls can be comfortably manipulated. On the left hand are the starting valve, injector valve and steam-jet valve ; on the right hand are the change-speed and the reverse levers. The driver can operate the foot brake to the rear wheels by his left foot and the steam-release valve by his right foot, whilst the small drainpipes from the cylinders and the injector water valve from the tank can be operated by either the driver or the fireman, as they are positioned between the two sets, The "cab has a very clear passage through and can be entered from either side of the vehicle.

The boiler feed pump is gear-driven from the crankshaft, the eccentric being fitted with roller bearings. This pump is of the double-acting type with two plungers in the same straight line.

The water tank is fixed at the rear of the chassis and has a capacity of about 194 gallons, sufficient to take the wagon, with full load, a distance of 30 miles, whilst the coal bunkers hold sufficient fuel for 60 miles.

The chassis frame is of rolled channel-steel, 7 ins. deep with 3-in. flanges, and it is strengthened where necessary with fish-plates.

The rear springs provide easy riding, their length being 4 ft. 6 ins. between the centres, the front ends being fixed and the rear ends being connected by shackles to the chassis frame, The 'steering gear is of the Ackerman

■ ••••• type, and the steering wheel is placed at the right-hand side of the vehicle, gear reduction from the hand steering wheel being taken

through a worm and worm wheel suitably housed in a cast-steel box whirls is totally enclosed and filled with oil. Centre-point steering is obtained by using dished cast-steel front wheels; whilst the axle ends are of the split type.' The rear wheels are of caststeel and are shod with twin solid tyres.

The brakes are of large dimensions, being operated by cams, the shoes-2 ft. 5 ins. in diameter—acting on a drum on each rear wheel and operated by a pedal.

The standard model has a platform length of 16 ft. This gives ample room on a normal wheelbase for a comfortable cab which thoroughly protects the driver and fireman. A full view of the road in front of them is given by the hollowing out of the front plate around the boiler at the sides, and this, incidentally, naturally improves the appearance of the front of the machine, which we think is very graceful.

The vehicle is equipped with an electric lighting set.