Put zip into small diesels

Page 139

Page 140

If you've noticed an error in this article please click here to report it so we can fix it.

• Roy Appleton of TB Turbo claims that fitting a turbocharer to a small diesel engine will raise its performance to the level of that of the equivalent capacity petrol engine. To see what is involved in fitting a turbo to a naturally aspirated diesel engine, Workshop went to the Lancaster works of TB Turbo and watched a Nissan Patrol being given the treatment.

What distinguishes the TB Turbo conversion from those of many of its competitors is that a new exhaust manifold is cast to take the Garrett integral wastegate turbo. The turbos are bought new, direct from Garrett, and although TB will rebuild the larger turbos that it fits to agricultural engines, which is most of its business, it will not attempt to overhaul, or remanufacture the smaller turbo.

As well as a new manifold, a new down pipe is made for the exhaust system, although on some conversions an entirely new exhaust system has to be fitted. As much of this equipment takes the space normally filled by the air filter, the original item is replaced by a barrel type filter connected to the turbo intake with a flexible hose.

An additional union at the turbo intake is connected to the rocker box breather via a T-piece. The other branch of the T-piece is connected to an additional crankcase breather that is drilled into the sump pan.

This drilling has a threaded boss MIG welded onto it to take a banjo union, and relieves the extra crankcase pressure generated by the harder working engine. It will also relieve the extra blow-by that is bound to leak past the piston rings as the engine wears, because of the increase in cylinder pressure.

An additional drilling and welded boss in the sump pan is connected to the turbo bearing to provide an oil drain. The feed is taken from an adaptor union fitted in between the oil-pressure light switch and the engine block.

When the engine first starts, the turbo takes a high oil flow, but once the reservoir around the floating bush bearings fills up, the flow is slowed down by the oil flowing through the bearings. These bearings can become damaged, by switching the engine off without allowing it to idle first. This is because the oil pump stops pumping when the turbo is still spinning hard, so starving the bearings. A sticker attached to the windscreen warns against such behaviour.

Roy Appleton of TB Turbo claims that not only does the conversion give a performance increase of around one third, but that the vehicle will actually use less fuel. He bases this claim on the ability of the vehicle to pull a higher gear, so although the injector pump is adjusted to enrich the mixture, less is used because it has to inject less often.

As the TB Turbo conversion does not extend to raising the rear axle ratio, this can be true only for vehicles that do much of their work in the intermediate ratios. A vehicle that works mostly in top gear will use as much if not more fuel as it will be working that much harder.

A subject on which Appleton is somewhat reticent is how the manufacturer's guarantee is affected by the fitting of a TB Turbo. Different manufacturers react in different ways to the aftemiarket turbo, and the deal can also depend on who the customer is: a customer such as the health authority that has had turbos fitted to its fleet of ambulances may expect to get a more sympathetic hearing than the individual opeator.

TB Turbo guarantees all the work and components that it does to a vehicle, and includes any direct damage that its work or parts cause, although apparently there has never been such a claim. If the manufacturer's guarantee on such unrelated items as the steering mechanism is nullified, an insurance to extend the manufacturer's warranty is available at an extra cost of £60.

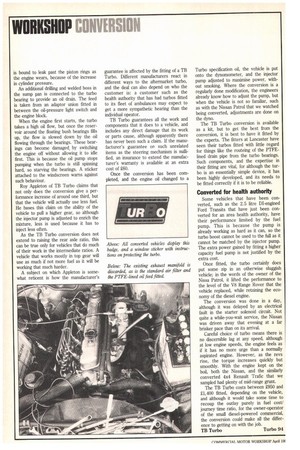

Once the conversion has been completed, and the engine oil changed to a Turbo specification oil, the vehicle is put onto the dynomometer, and the injector pump adjusted to maximise power, without smoking. Where the conversion is a regularly done modification, the engineers already know how to adjust the pump, but when the vehicle is not so familiar, such as with the Nissan Patrol that we watched being converted, adjustments are done on the dyno.

The TB Turbo conversion is available as a kit, but to get the best from the conversion, it is best to have it fitted by the experts. The fitters at Lancaster have seen their turbos fitted with little regard for things like the routeing of the PTFElined drain pipe from the turbo bearings. Such components, and the expertise in their fitting are vital, for although the turbo is an essentially simple device, it has been highly developed, and its needs to be fitted correctly if it is to be reliable.

Converted for health authorfty

Some vehicles that have been converted, such as the 2.5 litre DI-engined Ford Transits that have just been converted for an area health authority, have their performance limited by the fuel pump. This is because the pump is already working as hard as it can, so the turbo boost cannot be used to the full as it cannot be matched by the injector pump. The extra power gained by fitting a higher capacity fuel pump is not justified by the extra cost.

Once fitted, the turbo certainly does put some zip in an otherwise sluggish vehicle; in the words of the owner of the Nissa Patrol, it lifted the performance to the level of the V8 Range Rover that the vehicle replaced, while retaining the economy of the diesel engine.

The conversion was done in a day, although it was delayed by an electrical Mutt in the starter solenoid circuit. Not quite a while-you-wait service, the Nissan was driven away that evening at a far brisker pace than on its arrival.

Careful choice of turbo means there is no discernible lag at any speed, although at low engine speeds, the engine feels as if it has no more urge than a normally aspirated engine. However, as the revs rise, the torque increases quickly but smoothly. With the engine kept on the boil, both the Nissan, and the similarly converted 4x4 Renault Trafic that we sampled had plenty of mid-range grunt.

The TB Turbo costs between £950 and £1,400 fitted, depending on the vehicle, and although it would take some time to recoup the outlay purely in fuel cost/ journey time ratio, for the owner-operator of the small diesel-powered commercial, the conversion could make all the difference to getting on with the job.

TB Turbo Turbo 94