SCHEMES FOR VALVES AND VALVE CAPS.

Page 27

If you've noticed an error in this article please click here to report it so we can fix it.

Our Driver and Mechanic Readers' Suggestions.

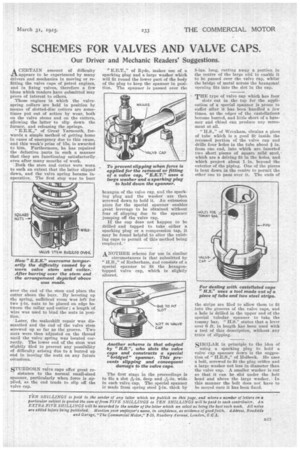

ACERTAIN amount of difficulty ..appears to be experienced by many drivers and mechanics in moving or refitting the valve caps of petrol engines, and in fixing valves, therefore a few ideas which readers have submitted may prove of interest to others.

Those engines in which the valvespring collars are held in position by means of slotted-disc cotters are sometimes put out of action by wear, both on the valve Stems and on the cotters, allowing the latter to slip down the former, and releasing the springs.

" E.E.K.," of Great Yarmouth, forwards a simple method of getting home in cases of emergency due to this cause, and this week's prize of 15s. is awarded to him. Furthermore, he has repaired the defective parts in such a manner that they are functioning satisfactorily even after many months of work.

Both the stem and cotter were worn to such an extent that the letter slipped down, and the valve spring became inoperative. The first step was to burr over the end of the stem and place the cotter above the burr. By levering up the spring, sufficient room was left for two i-in. nuts to be placed on edge between the collar and cotter ; a length of wire was used to bind the nuts in position.

Later, the makeshift repair was dismantled and the end of the valve stem screwed up so far as the groove. Two nuts were then adjusted on the thread until the valve spring was located correctly. The lower end of the stem was slightly filed to prevent any possibility of difficulty arising due to a burred up end in moving the nuts on auy future occasions.

STUBBORN valve caps offer great re

sistance to the normal small-sized spanner, particularly when force is applied, as the end tends to slip off the valve cap. E.E.T.," of Hyde, makes use of a sparking plug and a large washer which will fit round the lower part of the body of the plug to keep the spanner in position. The spanner is passed over the hexagon of the valve cap, and the sparking plug and the washer are then screwed down to hold it. An extension piece for the special spanner enables great leverage to be obtained without fear of slipping due to the spanner jumping off the valve cap.

IA the cap does not happen to be drilled and tapped to take either a sparking plug or a compression tap, it may be found helpful to alter the existing caps to permit of this method being employed.

ANOTHER scheme for use in similar circumstances is that submitted by " ILE.," of Rotherham, and consists of a special spanner to fit the hexagontopped valve cap, which, is slightly altered, The first stage in the proceedings is

to file a slot A-in. deep and wide in each valve cap. The specikl spanner

is made from spriug steel thick by

8-ins, long, cutting away a portion in the centre of the large end to enable it to be passed over the valve cap, whilst the bridge of metal across the hexagonal opening fits into the slot in the cap.

THE type of valve cap which has four

slots cut in the top for the application of a special spanner is prone to gaffer after it has been handled a few times, as the edges of the castellations become burred, and little short of a hammer and Chisel can produce any movement at all.

"U.S.," of Wrexham, obtains a piece . of tube which is a good fit inside the recessed portion of the valve cap and drills four holes in the tube about I in. from one end, into which are inserted two short pieces of square mild steel,which are a driving fit in the holes, and which project about 1 in. beyond the exterior of the piping. One of the pieces is bent down in the centre to permit the other one to pass over it. The ends of

the strips are filed to allow them to fit into the grooves of the valve caps, and a hole is drilled in the upper end of the special tubular spanner to take the tonuny bar. " H.S." states that a lever over 6 ft. in length has been used with a tool of this description, without any trace of slipping.

SIMILAR in principle to the idea of using a sparking plug to hold a valve cap spanner down is the suggestian of "II.E.S.," of Holbeck. He uses. a bolt, screwed to fit the plug orifice and a large washer not less in diameter than the valve cap. A smaller washer is cut so that it can be slid under the bolt head and above the large washer. In this manner the bolt does not have to be moyed once it has been fixed.