Revisions of Weldable Low-alloy Steels

Page 28

If you've noticed an error in this article please click here to report it so we can fix it.

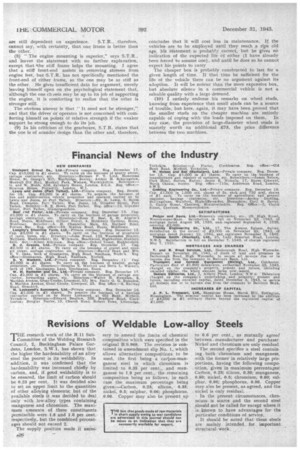

THE research work of the R.11 SubCommittee of the Welding Research Council, 2, Buckingham Palace Gardens, leondon, S.W.1, has shown that the higher the hardenability of an alloy steel the poorer is its weldability. In addition, it was confirmed that the hardenability was increased chiefly by carbon, and, if grrod weldability is to be ensured, the limit of carbon should be 0.23 per cent. It was decided also to set an upper limit to the quantities of other alloying elements; but of the available steels it was decided to deal only with low-alloy types containing manganese and chromium. The maximum amounts of these constituents permissible were 1.8 and 1.0 per cent. respectively, but the combined percentages should not exceed 2.

The supply position made it neceS ,s2p

sary to amend the limits of chemical composition which were specified in the original B.S.968. The revision is contained in amendment slip No. h which allows alternative compositions to be used, the first being a carlpon-manganese steel in which chromium is limited to 0.35 per cent., and manzanese to 1.8 per cent., the remaining composition being as follows, in each . case the maximum percentage being given:—Carbon, 0.23; silicon, 0.33; nickel, 0.5; sulphur, 0.06; phosphorus, 0.06. Copper may also be present :tap

to 0.6 per cent., as mutually agreed between , manufacturer And purchaser, Nickel. and chromium are only residual".

The second specifiess-a steel containing, both •chromium and manganese, with the former in relatively large propOrtions, having the following composition, given in maximum percentages: Carbon, 0.23; silicon, 0.35; manganese, 0.80; nickel, 0.5; chromium, 0.80; sul phur, 0.06; phosphorus, 0.06. Copper may. also be present, as agreed, and the nickel is only residual.

In the present circumstances, chromium is scarce and the second steel „should not be called for 'exceptwhere it is. known to have advantages for the particular conditions of service.

It should be noted that these steelsare mainly . intended . for importantstructural work.