THE STORING and

Page 42

Page 43

Page 44

If you've noticed an error in this article please click here to report it so we can fix it.

ANDLING of FUELS for Oil-engined Vehicles

UNTIL recent years petrol has been virtually the only fuel used for road vehicles propelled by internal-combustion engines. Formerly, it was handled and stored in two-gallon cans, but the keeping of .petrol in approved bulk-storage installations on the operator's premises is to-day standard practice.

Now that the compression-ignition engine has arrived, it might be thought that the saine type of bulk-storage outfit could safely be used for oil fuel, but such is not the case. Oil fuels have characteristics differing widely from those of petrois and, therefore, require different methods of storage and handling in order to ensure their delivery into the fuel tanks of the vehicles in a clean and proper condition. The leading oil companies supply fuels carefully prepared to give the best results, and the important factor, from the operator's standpoint, is that the fuel should reach the tanks and then the , engines in the cleanest possible condition.

For reasons of safety, petrol storage tanks have generally to be buried below ground. Oil fuel, however, owing to its high flash-point, does not come within the scope of the Petroleum Acts, so that storage of this fuel below ground is unnecessary. Actually, for reasons which will he explained later, underground storage is definitely undesirable.

Why Strict Cleanliness Must Be Observed.

The compression-ignition engine, with its delicate fuelinjection mechanism, is more liable to be adversely affected by fuel contamination than is the petrol engine. Furthermore, oil fuels are heavier, more viscous, less highly refined and more liable to pick up contaminating matter than petrol. For these reasons very careful attention should be given to the design and installation of the storage and delivery system in order to intercept maisture and other foreign matter and to ensure that only good, clean, fuel shall reach the vehicle tanks.

The chief objection to busied petrol tanks is that no provision is made for drawing off water and sediment, which may have accumulated at the bottom, before a fresh load of fuel is taken in. The fitting of a hand pump for this purpose presents considerable difficulties and is unlikely to be entirely satisfactory. Operators who have purchased oil-engined vehicles may sometimes be tempted by the offer of second-hand tanks at apparent bargain prices. Such tanks cannot be recommended for the storage of oil fuel. Although there may be a slight saving on the cost of the tank itself, it will almost certainly require alterations and the addition of various

accessories and, even then, it will certainly not be so satisfactory or so durable as an outfit which has been specially designed for the purpose.

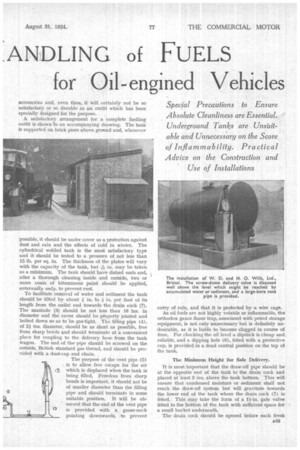

A satisfactory arrangement for a complete fuelling outfit is shown in an accompanying drawing. The tank is supported on brick piers above ground and, whenever possible, it should be under cover as a protection against dust and rain and the effects of cold in winter. The cylindrical welded tank is the most satisfactory type and it should be tested to a pressure of not less than 15 lb. per sq. in. The thickness of the plates will vary with the capacity of the tank, but A in. may be taken as a minimum. The tank should have dished ends and, after a thorough cleaning inside and outside, two or more coats of bituminous paint should be applied, externally only, to prevent rust.

To facilitate removal of water and sediment the tank should be tilted by about i in. to 4 in, per foot of its length from the outlet end towards the drain cock (7). The manhole (8) should be not less than 16 ins. in diameter and the cover should be properly jointed and bolted down so as to be gas-tight. The filling pipe (4), of 21 ins, diameter, should be as short as possible, free from sharp bends and should terminate at a convenient place for coupling to the delivery hose from the tank wagon. The end of the-pipe should be screwed on the outside, British standard gas thread, and should be provided with a dust-cap and chain.

The purpose of the vent pipe (5) is to allow free escape for the air 1?i

being filled. Freedom from sharp 13 which is displaced when the tank is bends is important, it should not be of smaller diameter than the filling

pipe and should terminate in some suitable position. It will be observed that the end of the vent pipe 12 is provided with a goose-neck 1 I

pointing downwards, to prevent entry of rain, and that it is protected by a wire cage. As oil fuels are not highly volatile or inflammable, the orthodox gauze flame trap, associated with petrol storage equipment, is not only unnecessary but is definitely un desirable, as it is liable to become clogged in course of time. For checking the oil level a dipstick is cheap and reliable, and a dipping hole (8), fitted with a protective cap, is provided in a dead central position on the top of the tank.

The Minimum Height for Safe Delivery.

It is most important that the draw-off pipe should be at the opposite end of the tank to the drain cock and placed at least 3 ins, above the tank bottom. This will ensure that condensed moisture or sediment shall not reach the draw-off system but will gravitate towards the lower end of the tank where the drain cock (7) is fitted. This may take the form of a iFin. gate valve fitted to the bottom of the tank with sufficient space for a small bucket underneath.

The drain cock should be opened before each fresh delivery of oil and any sediment or water withdrawn, otherwise these impurities would be stirred up and mixed with the incoming oil.

A screw-down gate valve (6) is fitted to the outlet end and from here a pipe of not less than 11 in. diameter leads to the suction side of the pump (12). After passing through the gate valve the oil enters a cage-type filter (10). This should be large enough to permit of easy flow of the oil and should have a ,suitable gauze of non-corrodible metal and with at least 120 meshes per linear inch. It should be easily accessible and should be cleaned at weekly intervals at least.

Storage tanks should be of mild-steel ship-quality plate, and black iron piping of steam quality should be used throughout. Galvanized metals should not be employed for any portion of the installation coming into contact with the oil.

A Good Installation Relatively Inexpensive.

The cost of a first-class storage installation is small when compared with the cost of a new vehicle, and it is not a recurring expenditure. Hence, although the fuel for compression-ignition-engined vehicles can be obtained in barrels, this method is not recommended, for, besides being laborious and inefficient, it is much more expensive for the operator. It sometimes happens, however, that oil must be taken in barrels as a temporary measure.

Barrels should be stored under cover in a sheltered position and their contents should be given time to settle. A few days before the oil is required a tap should be inserted in the hole provided in the end of the barrel, which should then be set on its side at a suitable height.

An accompanying drawing shows a good arrangement and it will be noticed that the barrel is tilted slightly backwards away from the tap. The draw-off vessel should be of non-galvanized metal and the bung, which

will need to be removed to enable the oil to run out, should be replaced immediately afterwards. When pouring the oil into the tank of the vehicle a funnel filter, having a gauze of nOt less than 120 meshes per linear inch, should be employed. It is of the utmost importance to keep both the measure and the funnel absolutely clean. They should be covered up when not in use, as a dirty or dusty fiumel inserted into the tank of the vehicle might defeat all the previous precautions. The last dregs in the barrel should not be used.

If oil fuel is stored and handled in accordance with these recommendations, it is safe to assume that it will be in a clean state when delivered into the tank of the vehicle. The maker of the engine has, however, taken additional precautions by providing a series of filters between the vehicle fuel tank and the injection pump. These filters should be dismantled and cleaned at least every fortnight or after 2,000 miles running. Any dirt present can be removed by rinsing the filter in paraffin or clean oil fuel. On no account must the internal parts be cleaned with cotton waste. If the filtering element is very dirty, boiling in paraffin will clean it effectively.

Careless Methods and Low-grade Fuels to be Avoided.

Furthermore, road dust', dirt and condensed moisture may find their way into the vehicle fuel tanks. It is, therefore, important that these should also be inspected periodically and, where necessary, cleaned out. As dirt and impurities in the fuel may seriously impair the efficiency and reliability of an oil engine, operators cannot be too careful, both in their choice of a suitable fuel and in the method of storing and handling it.

Drivers and garage staffs should all receive explicit instructions on these vital subjects as the taking of proper precautions assists trouble-free running, reduces repair bills and prolongs the life of the engine.