The Lubrication of Laminated Springs

Page 76

If you've noticed an error in this article please click here to report it so we can fix it.

A Résumé of Recently Published Patent Specifications

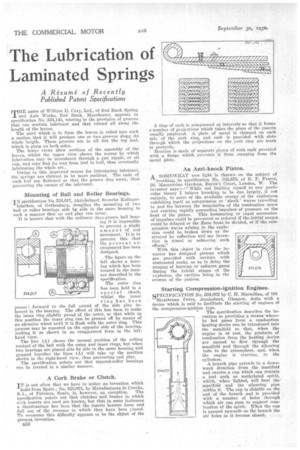

TET E name of William E. Cary, Ltd., of Red-Bank Spring and Axle Works, Red Bank, Manchester, appears in specification No. 334,143, relating to the provision of grooves that can contain lubricant and that extend all along the

length of the leaves. , The steel which is to form the leaves is rolled into such a section that it will produce one or two grooves alopg its whale length. These grooves are in all but the top leaf, which is plain on both sides. •

The lower views show sections of the assembly of the leaves, whilst the upper view shows the means. by which lubrication may be 'introduced through a gun nipple, or oil cup, and may find -its way from leaf to leaf, thus eventually lubricating the whole set..

Owing to this improved means for introducing lubricant, the syrings are claimed to be more resilient. The ends of each leaf are flattened so that the 'groove dies away, thus Preventing the escape of the lubricant.

Mounting of Ball and Roller Bearings.

-IN specification No. 334,017, Aktiebolaget Svenska. Kullagerfahriken, of Gothenburg, desoribes the mounting of two ball or roller bearings side by side in the same housing in such a manner that no end play can occur.

It is known that with the ordinary deep-groove ball bearing it is impossible to prevent a slight amount of end movement. It is to prevent this that tho present arrangement has been designed.

The figure on the left shows a bearing which has been treated in the manner described in the specification.

The outer ring has been held in a special chuck, whilst the inner ring has been presse forward to the full extent of the side play inherent in -the bearing. The effect of this has been to make the inner ring slightly proud of the outer, so that while in this position the inner ring can be ground off by means of an abrasive: wheel until it is flush with the outer ring. This process may be repeated on the opposite side of the bearing, making it as shown in an exaggerated form in the lefthand 'view.

The line (A). shows the normal position of the rolling

contaceof the ball with the outer and inner rings, but when two bearings are placed side by side in the same housing and gripped together the Hiles (A) will take up the position shown in the right-hand view, thus preventing end play.

The specification points out that tapered-roller bearings can be treated in a similar manner.

A Cork Brake or Clutch.

IT is not often that we have to notice an invention which hails from Spain ; No. 333,073, by Manufactures do Corcho,

S.A., of Palamos, Spain, is, however, an exception. The specification points out that clutches and brakes in which cerle inserts are used are known, but that in some instances a disadvantage has been that the inserts become loose and fall out of the recesses in which they have been ylaced. To overcome this difficulty appears to be the object of the present invention.

A ring of cork is compressed at intervals so that it forms a number of projections which takes the place of the inserts usually employed. A plate of metal is clampe-d on each side ' of the cork ring, and each is provided with slots through which the projections on the cork ring are made to protrude.

Mention is made of separate pieces of cork each provided with a flange which prevents it from escaping from the metal plate.

An Anti-knock Piston.

A SOMEWHAT new light is thrown on the subject of knocking, .in specification No. ,333,878, of R. P. Fraser, 20, Margravine Gardens, Baron's Court, London, W. The inventor says:—" While not limiting myself to any particular theory I believe knocking to be due largely, if not entirely, to some of the, available energy of the explosions exhibiting itself as compression or shock' waves travelling to and fro between the boundaries of the combustion space and exerting rapidly succeeding impulses of pressure on the head of the piston. This hammering or rapid succession of impulses could be prevented or reduced if the initial surges could be delayed or the frame front be divided, or if the compression waves arising in the explo

sion could be. broken clown or destroyed by reflection and my invention is aimed at achieving such erects."

With this object in view theinventor has designed pistons which are provided with cavities with contracted necks, so as to delay the surging of burning or unburnt gases during the initial stages of the explosion, the cavities being in the crowns of the pistons.

Starting Compression-ignition Engines.

SPECIFICATION No. 334,072 by C. H. Macmillan, of 101 Strathcona -Drive, Anniesland, Glasgow, deals with a device which is said to facilitate the starting of engines of the compression-ignition type.

The specification describes the invention as providing a means whereby hot gases from a combustion heating device can be introduced into the manifold so that, when the engine is at rest, the products of combustion from the heating device are caused to flow through the manifold and through the silencing tube to the atmosphere, and, when the engine is starting, to the cylinders.

A branch pipe extends in a downward direction from the manifold and carries a cup which can contain a fuel such as methylated spirit, which, when lighted, will heat the manifold and the silencing pipe .within it. The cup is slidabie on the end of the branch and is provided with a number of holes through which air can pass to support combustion of the spirit. When the cup is pressed upwards on the branch the air holes in it become closed.