HE NEW PAG

Page 58

Page 59

Page 60

If you've noticed an error in this article please click here to report it so we can fix it.

7IELD GARDNER

5-6-TON DI 3EL LORRY

First and Full Particulars of a Fin Gardner Power Unit. Fully Loaded Over chicle In a Four-cylindered Machine is Capable of Maintaining

T HE steady progress of the Diesekengined commercial vehicle continues, slowly, perhaps, but • nevertheless surely. We have recently had an opportunity for inspecting and trying a particularly fine-looking chassis built by that old-established British ccncern, Walker Bros. (Wigan), Ltd., of Pagefield Ironworks, Wigan, the maker of Pagefield products. The new machine, called the Pagefield-Gardner Diesel lorry, is a thoroughly sound adaptation.of the normal Pagefield chassis, incorporating a four-cylindered Gardner engine in place of the usual petrol unit.

With wheelbase and track dimensions of 14 ft. 9 ins. and 5 ft. 9 ins. (front) and 5 ft. 7 ins. (rear) respectively, it has been found possible to install a platform body measuring 14 ft. long by 7 ft. wide, with a rear overhang of only 4 ft. 10i ins. As might be expected, a straight frame is used, the loading height being 3 ft. 9 ins, and the frame height 2 ft. 8i. ins.

The main channels are 8 ins, deep and are coverplated at the top and the bottom by Fin. plates, whilst the cross-members are of proportionately deep section and provide a thoroughly rigid bracing at all points. The general design follows normal practice, semielliptic springs being used all round, those at the rear being shackled at both ends in order to provide for the fore and aft movement during articulation of the controlled rear axle; fuller particulars of the final drive will be found later on in this article. The bare chassis weighs about four tons, the pay load being 5-6 tons.

Details of the Oil Engine.

It will be recalled that in our issue for last week we described fully the Leeds Corporation Crossley doublesaloon bus with Gardner six-cylindered Diesel engine. It is, however, best that we give some details of this four-cylindered unit of the same make.

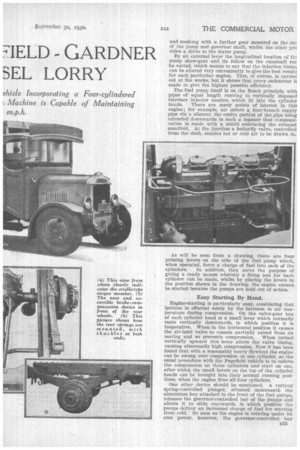

Mounted in the chassis on four cast-steel brackets, the engine "sits" into the frame very nicely and, despite the relatively largq bore and stroke dimensions of 44 ins. and 6 ins, respectively, the unit does not appear to be at all on the large side.

The Gardner engine is well finished and very cleanly designed, with the cylinders cast in pairs and the crankcase divided at the centre line of the crankshaft. The lower half is built -unitwise with the sump and strikes something of a new note in that it carries the five bearings for the crankshaft, the upper section being merely a framework on to which the cylinder blocks are mounted; this casting, however, carries the camshaft. This arrangement permits the whole engine to be dismantled while it remains in the chassis.

The auxiliary drive is more than ordinarily interesting. From the crankshaft a duplex miler chain embraces, a sprocket on the camshaft, but behind this sprocket are two skew gears, one having wide teeth

n32 and meshing with a further gear mounted on the eM of the pump and governor shaft, whilst the other pro vides a drive to the water pump.

By an external lever the longitudinal location oi: thf. pump skew-gear and its fellow on the camshaft car be varied, which means to say that the injection timirq can be altered very conveniently to give the best results for each particular engine. This, of course, is carried out at the works, but it shows that every endeavour is made to give the highest possible efficiency.

The fuel pump itself is on the Bosch principle, with pipes of equal length running to vertically disposed Gardner injector nozzles, which fit into the cylinder heads. There are many points of interest in this engine; for example, air enters a four-branch supply pipe via a silencer, the centre portion of the pipe being extended downwards in such a manner that ccinniunication is made with a shield embracing the exhaust manifold. At the junction a butterfly valve, controlled from the dash, enables hot or cold air to be drawn in.

As will be seen from a drawing, there are four priming levers on the side of the fuel pump which, when operated, force a charge of fuel into each of the

cylinders. In addition, they serve the purpose of giving a ready means whereby a firing test for -each cylinder can be made, whilst by placing the levers in the position shown in the drawing, the engine cannot be started because the pumps are held out of action.

Easy Starting By Hand.

Engine-starting is particularly easy, considering that ignition is effected solely by the increase in air temperature during compression: On the valve-gear box of each cylinder head is a small lever which normally rests vertically downwards, in which position it is Inoperative. When in the horizontal position it causes the air-inlet valve to remain partially raised from its seating and so prevents compression. When turned vertically upward this lever alters the valve timing, causing abnormally high compression. Now it has been found that with a reasonably heavy flywheel the engine can be swung over compression en one cylinder, so the usual procedure with the Pagefield vehicle is to relieve the compression on three cylinders and start on one, after which the small levers on the top of the cylinder heads can be brought into their normal running positions, when the engine fires all four cylinders.'

One other device should be mentioned. A vertical spring-controlled plunger, situated underneath the aluminium box attached to the front of the fuel pumps, releases the governor-controlled bar of the pumps and allows it to slide rearwards, in which position the pumps deliver an Increased charge of fuel for starting from cold. So soon as the engine is rotating under its own power, however, the governor-controlled bar automatically retakes its normal working position, so the pump cannot give an excessive charge of fuel.

The normal range of revolution speeds is from 400 r.p.m. to 1,300 r.p.m., at which speed a maximum output of 50 b.h.p. is obtained. To give an idea of the power-curve characteristic it may be mentioned that at 1,000 r.p.m. 38 b.h.p. is delivered at the flywheel.

A large-diameter cone clutch, faced with Ferodo friction material, is operated directly by the pedal, double ball-bearing races being used to take care of the withdrawal thrust. A short cardan shaft with fabric discs at each end transmits the power to a four-speed gearbox of really substantial Construction. The box itself is an aluminium casting with a web running across its centre to support the main and lay shafts. The gears themselves are a beautiful fit on the shafts and with wide teeth and deep internal splines are ideally suited to transmit the heavy torque of the power unit. The ratios in the box are 1.66, 3.0 and 5.1 to 1, which, in conjunction with the rear axle, gives the following overall ratios : top, 7.825 to 1; 3rd, 13 to 1; 2nd, 45 to 1; 1st, 40 to 1; and reverse, 35.7 to 1. The top-gear ratio of 7.825 to 1 is so planned that, bearing in mind the tyre sizes and the governed speed of the engine (1,300 r.p.m.), a speed of 22 m.p.h. is possible.

The foot brake operates on a drum which is mounted on the tailshaft of the gearbox, a pair of rigid contracting shoes being coupled by a simple system of levers, so that movement of the pedal rod rotates a pair of cam surfaces on a shaft passing through the lower extremities of the shoes. A hand wheel provides for adjustment of the drum-shoe clearances.

The propeller shaft and torque member are of most substantial construction. Hardy Spicer joints provide for articulation of the former component, whilst the forward end of the cast-steel cradle-like torque member is housed, through the medium of a spherical joint, in a deep channel-sectioned crosS-member. Particular interest attaches to the construction of the axle. Double-reduction gearing is employed, the first reduction being effected by spiral bevel gear and the second by plain spur gears, the differential being incorporated in the spiral-bevel crown wheel.

The main casing is machined from a solid forging and is, in consequence, immensely strong; cast-steel nose and tail housings are also very rigid in construction and are so arranged that the whole of the axle shafts, etc., can be dismantled with the road wheels on the ground. The hand-brake lever applies internal n31 expanding shoes in drums attached to both rear wheels.

Normally, the chassis, which is priced at 11,325, has 38-in. by 7-in. tyres, with twin equipment at the rear, and is supplied with a spare wheel and tyre, whilst a 12-volt electric lighting outfit, a power tyre pump, grease-gun chassis lubrication and front wings are also included in the specification. For a fiat platform lorry with cab and four wings the price is 11,425.

We saw the engine started up on four occasions while we were at the Pagefleld works and each time it "fired" at the very first time of asking. A good, sharp swing is, of course, required, but the necessary effort is not at all beyond thefl power of ordinary drivers. After a few minutes' idling, while the watercirculation and lubrication systems were allowed to warm up, we set out on a short run around the outskirts of Wigan. It soon became apparent that a splendid average speed could be maintained, despite a full load of 6 tons, for on all level going 20 m.p.h. seemed to be well within the scope of the engine, whilst on slight up grades the manner in which the engine would "hang on" when the speed began to fall was quite remarkable.

The great charm of this new Pag-efield chassis, however, lies in the unostentatious manner in which the power unit functions. It is not noisy, does not vibrate , and provides a thoroughly smooth torque throughout its whole range of speed. In other words, one cannot tell whether a good petrol engine is installed beneath the bonnet or a Diesel unit.

We tried the fully laden vehicle up a steep hill of about 1 in 6 to 1 in 7 and found that, although it was just too steep for second gear, there was ample power in hand on first. No sign of boiling was apparent, despite the fact that a fan is not used, whilst the "hot smell" often experienced on a petrol chassis after a long climb was absent. The brakes are good.

All the controls work quite smoothly. The clutch, for example, takes up the drive without any suspicion of harshness, whilst the steering wheel (which actuates a Bishop reduction gear) is quite light to the touch and is direct in action. Gear-changing, too, is quite smooth and is facilitated by an effective clutch stop.

Altogether it appears to he an excellent vehicle and one which should amply repay its manufacturer for its pioneering efforts. The machine we inspected and tried was already sold to the Barton Transport Co., Ltd., of Burton-on-Trent, through the medium of the new sales organization—Pagefield Commercial Vehicles subsidiary of Walker Bros. (Wigan), Ltd.