THE DAIMLER PASSENGER CHASSIS

Page 52

Page 53

If you've noticed an error in this article please click here to report it so we can fix it.

in Its Newest Form

Modified Frame and Transmission to Give Lower Floor Height. The Sleevevalve Engine Improved in Several Respects

THE new Daimler CG6 chassis, which is available in forms suitable for double-deck and singledeck passenger bodies, may be looked upon as the logical development of the successful CF6 model. We recently visited the works of the Daimler Co., Ltd., at Coventry, to examine the new chassis and its components in course of manufacture and are privileged in being able to publish the first full account of it. The CF6 chassis will still be available at a price of £1,075 for the single-deck and £1,100 for the double-deck model, these prices comparing with £1,150 for the CG6 double-deck model. The price for the single-deck CG6 chassis is not yet settled.

New Chassis Layout.

The frame, transmission and springing have been modified considerably with the object of obtainr lag a lower frame height, and a reduction of 3i inshas been made, the frame top between the axles being now 1 ft. 9 ins, high under load. The rear frame extension for the conductor's platform on the chassis intended for double-deck bodies is now 11 ins, above the ground, these measurements being obtained with 36-in. by 8-in, low-pressure front tyres and 38-in. by 0-in, twin low-pressure rear tyres. The actual inflated diameter of the front tyres is 38.11 ins, and that of the rear tyres 38.74 ins.

The main frame-members are 11 ins, deep and are arched over the front and rear axles in normal fashion. A particularly good point, however, is the frame width, this B26 being no less than 3 ft. 11i ins. This satisfactory width has been obtained by locating ,the spring brackets and shackles immediately beneath the framemembers. All springs are of the inverted-camber kind, with Silentbloc bushes and Luvax hydraulic recoil dampers ; both front and rear springs are mounted slightly higher at their forward ends.

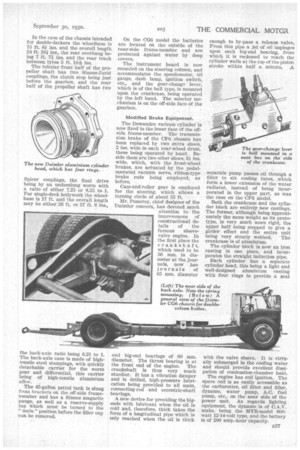

The transmission line has been offset. The engine has four-point suspension between the front crossmember and the cast-aluminium bridge which arches over the flywheel and the clutch housing. The gearbox is a separate unit mounted at three points between a tube at the front end and a slightly arched channel-section cross-member at the rear, therebeing a large-diameter tubular cross-member between this and the engine. Another such crossmember is located between the forward mountings of the rear springs, one of smaller diameter being placed nearly opposite the rear shackles, whilst a cruciform member is employed in the frame overhang. In the case of the chassis intended for double-deckers the wheelbase is 15 ft. 6 ins, and the overall length 24 ft. 10i ins., the rear overhang being 7 ft. 7i ins, and the rear track between tyres 5 ft. 10T3g ins.

The tubular front half of the propeller shaft has two Simms-Jurid couplings, the clutch stop being just before the gearbox, and the rear half of the propeller shaft has two Spicer couplings, the final drive being by an underslung worm with a ratio of either 7.25 or 8.25 to 1. For single-deck bodywork the wheelbase is 17 ft. and the overall length may be either 26 ft. or 27 ft. 6 Ins., the back-axle ratio being 6.25 to 1. The back-axle case is made of hightensile steel stampings, with quickly detachable carrier for the worm gear and differential, this carrier being of high-tensile aluminium alloy. _ The 45-gallon petrol tank is slung from brackets on the off-side framemember and has a Simms magnetic gauge, as well as a reserve-supply tap Which must be turned to the " main " position before the filler cap can be removed. On the CG6 model the batteries are located on the outside of the near-side frame-member and are protected against water by deep covers.

The instrument board is now mounted on the steering column, and accommodates the speedometer, oil gauge. dash lamp, ignition switch, etc., and the gear-change lever, which is of the ball type, is mounted upon the crankcase, being operated by the left hand. The selector mechanism is on the off-side face of the gearbox.

Modified Brake Equipment The Dewandre vacuum cylinder is now fixed to the inner face of the offside frame-member. The transmission brake of the CF6 chassis has been replaced by two extra shoes, 2 ins, wide in each rear-wheel drum, these being operated by hand. Beside them are two other shoes, n ins. wide, which, with the front-wheel brakes, are actuated by the pedaloperated vacuum servo, ribbon-type brake rods being employed, as before.

Cam-and-roller gear is employed for the steering, which allows a turning circle of about 55 ft.

Mr. Pomeroy, chief designer of the Daimler concern, has devoted much attention to the improvement of constructional details of the famous sleevevalve engine. In the first place the crankshaft, which used to be 56 mm. in diameter at the journals, now has journals of 65 mm. diameter and big-end bearings of 60 mm. diameter. The thrust bearing is at the front end of the engine. The crankshaft is thus very much sturdier. It has a vibration damper and is drilled, high-pressure lubrication being provided to all main, connecting-rod and eccentric-shaft bearings.

A new device for providing the bigends with lubricant when the oil is cold and, therefore, thick takes the form of a longitudinal pipe which is only reached when the oil is thick enough to by-pass a release valve. From this pipe a jet of oil impinges upon each big-end bearing, from which it is reckoned to reach the cylinder walls at the top of the piston stroke within half a minute. A separate pump passes oil through a filter to six cooling tubes, .which form a lower extension of the water radiator, instead of being incorporated in the upper part, as was the case on the CF6 model.

Both the crankcase and the cylinder block are entirely new castings. The former, although being approximately the same weight as its prototype, is very much more rigid, the upper half being stepped to give a girder effect and the entire unit being very stoutly webbed. The crankcase is of aluminium.

The cylinder block is now an iron casting in one piece, and incorporates the straight induction pipe.

Each cylinder has a separate cylinder head, this being a light and well-designed aluminium casting with four rings to provide a seal with the valve sleeve. It is virtually submerged in the cooling water and should provide excellent dissipation of combustion-chamber heat.

The engine has coil ignition. The spare coil is as easily accessible as the carburetter, oil filter and filler, dynamo, water pump, A.C. fuel pump, etc., on the near side of the power unit. As regards lighting equipment, the dynamo is of C.A.V. make, being the MYR-model 600watt 12-14-volt type, and the battery is of 200 amp.-hour capacity.