Sussex Tippers for Arduous Tasks

Page 37

If you've noticed an error in this article please click here to report it so we can fix it.

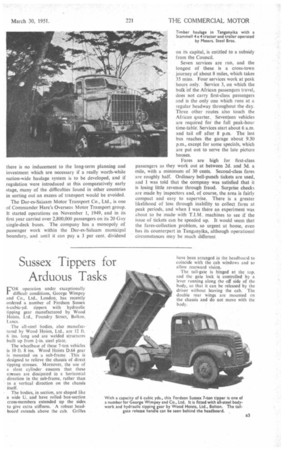

VOR operation under exceptionally difficult conditions, George Wimpey and Co., Ltd., London, has recently ordered a number of Fordson Sussex 6-cubic-yd. tippers with hydraulic tipping gear manufactured by Wood Hoists, Ltd., Foundry Street, Bolton, Lancs.

The all-steel bodies, also manufactured by Wood Hoists, Ltd., are 12 ft. 6 ins, long and are welded structures built up from On. steel plate.

The wheelbase of these 7-ton vehicles is 10 ft, 8 ins. Wood Hoists D.64 gear is mounted on a sub-frame This is designed to relieve the chassis of direct tipping stresses. Moreover, the use of a slant cylinder ensures that these stresses are dissipated in a horizontal direction in the sub-frame, rather than in a vertical direction on the chassis itself.

The bodies, in section, are shaped like a wide U, and have rolled, box-section cross-members extended up the sides to give extra stiffness. A robust headboard extends above the cab. Grilles

have been arranged in the headboard to coincide with the cab windows and so allow rearward vision.

The tail-gate is hinged at the top, and the gate lock is controlled by a lever running along the off side of the body, so that it can be released by the driver without leaving the cab. The double rear wings are mounted on the chassis and do not move with the body.