WEIGHING UP

Page 42

Page 43

If you've noticed an error in this article please click here to report it so we can fix it.

THE PNALT

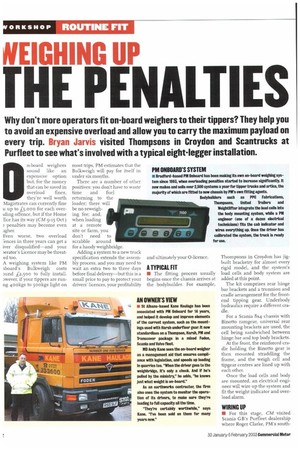

Why don't more operators fit on-board weighers to their tippers? They help you to avoid an expensive overload and allow you to carry the maximum payload on every trip. Bryan Jarvis visited Thompsons in Croydon and Scantrucks at Purfleet to see what's involved with a typical eight-legger installation.

n-board weighers sound like an expensive option but, for the money that can be saved in

overload fines, they're well worth Magistrates can currently fine u up to £5,000 for each overiding offence, but if the Home fice has its way (CM 9-15 Oct ) 2 penalties may become even lgher.

Even worse, two overload Eences in three years can get a iver disqualified—and your )erator's Licence may be threated too.

A weighing system like PM iboard's Bulkweigh costs Dund L2,5oo to fully install. Dwever, if your tippers are runng 4 ookgs to 5 ookgs light on most trips, PM estimates that the Bulkweigh will pay for itself in under six months.

There are a number of other positives; you don't have to waste time and fuel returning to the loader; there will be no reweighing fee; and, when loading at a remote site or farm, you don't need to scrabble around for a handy weighbridge.

Adding a system to a new truck specification extends the assembly process, and you may need to wait an extra two to three days before final delivery—but this is a small price to pay to protect your drivers' licences, your profitability and ultimately your 0-licence.

A TYPICAL FIT

• The fitting process usually begins once the chassis arrives at the bodybuilder. For example, Thompsons in Croydon has jigbuilt bracketry for almost every rigid model, and the system's load cells and body system are added at this point.

The kit comprises rear hinge bar brackets and a trunnion and cradle arrangement for the frontend tipping gear. Underbody hydraulics require a different cradle.

For a Scania 8x4 chassis with Binotto ramgear, universal rear mounting brackets are used, the cell being sandwiched between hinge bar and top body brackets.

At the front, the reinforced cradle holding the Binotto gear is then mounted straddling the frame, and the weigh cell and tipgear centres are lined up with each other.

Once the load cells and body are mounted, an electrical engineer will wire up the system and fit the weight indicator and overload alarm.

WIRING UP • For this stage, CM visited Scania GB's Purfleet dealership where Roger Clarke, PM's south

east England engineer, was alx to 'wire-up' another Scania eig legger.

An experienced technici Clarke first secures the syster junction box in a safe positi mid-way along a chassis rail, th routes all four load-cell cables the box. Tippers working rough sites often sustain a lot underside damage, hence t sensible provision of lots of ex cabling which is wound ir loops and secured inside t frame.

Another plug-in cable is r from the junction box up into t cab, where it connects with t PM treroD weight indicator another cable.

After mounting the audil alarm under the front pan Clarke routes the cables out sight behind the bulkhead a dashboard panelling, before tn. ming them to fit and pluggi them neatly into the load indil tor. The reader unit can mounted in a number of po tions, such as on the engine cm or on the dash. Here, it's fitt into the roof, where it is visit and accessible but out of ham way.

After verifying the system working correctly, Clarke re: cures any loosened panelling a: closes the job card.

CALIBRATION

• System calibration is norma done by the driver using deta supplied with the installation if necessary, you can contact o of PM's approved fitting ager for help.

Weighing the complett empty tipper, the driver enters t weight into the indicator syste, He then loads the vehicle to below the gross limit, subtrac one figure from the other I establish his payload) and entt this figure into the indicat memory.

The system will now show € vehicle's gross weight, and audible or visual alarm lets hi know when he reaches the pre limit.