BRAKE CHECK

Page 38

Page 39

Page 40

If you've noticed an error in this article please click here to report it so we can fix it.

• With the roller brake tester sited by the workshop entrance, any vehicle driven Inside to the hydraulic lift in the inspection area would begin by having its braking performance checked out First, the mechanic would ensure that there was no drum ovality, before checking the performance of each wheel on each axle, to see that there was no snatching, binding or any Imbalance in braking effort. Bearing in mind that usually there would be no load in the back, he would check out the braking force of each axle, before the wheels begin to lock up.

BRAKE LININGS

W Replacing brakes shoes is costly, time-consuming work but if the rubber plugs for the viewing aperture aren't replaced at every check, needless problems will arise, says Morris. Without them, dirt gets through the apertures and in between shoes and drums. it turns into a carborundum paste that can affect braking performance and cause premature wear of the linings, with scoring of the drums too. While checking the front brakes, see that the auto-lube is acting on the swivel pins.

PROPSHAFTS

Check that the propshaft U/J journals are being greased regularly, and the centre bearing too. If left for too long, they'll quickly begin to deteriorate. Don't neglect the short rear shaft either—there's not much space between the back axles and, with a dirty tipper grounded, some drivers will conveniently forget to do it.

Unlike a steering column 11/J, a driver won't feel either of them stiffening, and if he's on a long run home, he may not hear them squealing either. if they do break up, it will be when you least expect it. Don't forget to examine the bracket adjacent to the centre bearing mounting bolts. They occasionally crack and break free.

CAB INTAKE ALTER

• After checking all the fluid levels from under the front panel—engine oil, water, screenwash etc—Morrr, always looks at the cab air intake fitter. Situated centrally, just beneath the windscreen, it prevents most of the dust and pollen from getting inside. Considering that only two small swivel clips hold it in place, and takes no more than a couple of minutes to replace, it's amazing how often it's overlooked. If neglected, the driver's going to breathe in all the muck and dust that should have been filtered.

RADIATOR GUARD

III The heavy staid plate under the radiator protects the lower reservoir and hose from site damage by tree roots, branches, mud and rocks. Unfortunately, when reversing into a tipping position, the same protection plate becomes a very effective scoop that can dig up material and compact it under the radiator. Drivers should clear it out at least once a week. Compaction can damage the bottom of the radiator but even worse, the hose becomes squashed, restricts the coolant flow and causes engine overheating. A packed scoop is heavy self it needs removing for repair, rake the rubble clear first; otherwise, an unwary mechanic could be injured,

SPRING SHACKLES

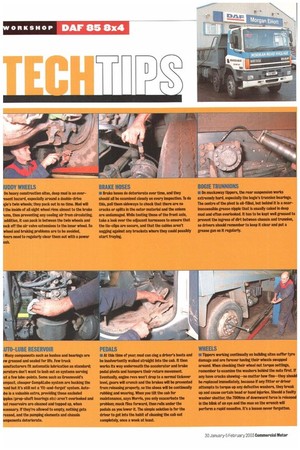

It Don't fall Into the trap of believing that front spring shackles frtted with automatic greasing never wear through. "They do," says Morris, "and it's Important to regularly check them in the usual way." Insert a long steel crowbar between the shackles and lever it up and down to test for any excessive wear in the bushes or pins. If worn shackles are left for too long, it can affect the steering, braking and general handling as well as causing adverse tyre wear too. IUDDY WHEELS On heavy construction sites, deep mud is an everssent hazard, especially around a double-drive igie's twin wheels; they pack out in no time. Mud will I the inside of all eight wheel rims almost to the brake .urns, thus preventing any cooling air from circulating. addition, it can pack in between the twin wheels and lock off the air valve extensions to the inner wheel. So wheel and braking problems are to be avoided, ivers need to regularly clear them out with a power ash, BRAKE HOSES I Brake hoses do deteriorate over time, and they should all be examined closely on every inspection. To do this, pull them sideways to check that there are no cracks or splits in the outer material and the unions are undamaged. While testing those of the front axle, take a look over the adjacent harnesses to ensure that the tie-clips are secure, and that the cables aren't sagging against any brackets where they could possibly start fraying. BOGIE TRUNNIONS I On muckaway tippers, the rear suspension works extremely hard, especially the bogie's trunnion bearings. The centre of the pivot is oil-filled, but behind it is a nearinaccessible grease nipple that is usually caked in deep mud and often overlooked. It has to be kept well greased to prevent the ingress of dirt between chassis and trunnion, so drivers should remember to keep it clear and put a grease gun on it regularly.

LUTO-LUBE RESERVOIR

Many components such as bushes and bearings are AV greased and sealed for life. Few truck lanufacturers fit automatic lubrication as standard; misters don't want to lash out on systems serving st a few lube-points. Some such as Groeneveld's impact, cheaper CompALube system are bucking the 'end but it's still not a 'fit-and-forget' system. Autobe is a valuable extra, providing those excluded pples (prop-shaft bearings etc) aren't overlooked and let reservoirs are cleaned and topped up, when nessary. If they're allowed to empty, nothing gets 'eased, and the pumping elements and chassis imixments deteriorate.

PEDALS ler At this time of year, mud can clog a driver's boots and be inadvertently walked straight into the cab. It then works its way underneath the accelerator and brake pedal pivots and hampers their return movement. Eventually, engine revs won't drop to a normal tickover level, gears will crunch and the brakes will be prevented from releasing properly, so the shoes will be continually rubbing and wearing. When you tilt the cab for maintenance, says Morris, you only exacerbate the problem; muck flies forward, then rolls under the pedals as you lower it. The simple solution is for the driver to get into the habit of cleaning the cab out completely, once a week at least. WHEELS 111 Tippers working continually on building sites suffer tyre damage and are forever having their wheels swapped around. When checking their wheel nut torque settings, remember to examine the washers behind the nuts first. If any have cracks showing—no matter how fine—they should be replaced immediately, because If any fitter or driver attempts to torque up any defective washers, they break up and cause certain head or hand induries. Should a faulty washer shatter, the 700Nms of downward force is released In the blink of an eye and the man on the wrench will perform a rapid nosedive. It's a lesson never forgotten.