TENDENCIES IN CHASSIS DESIGN

Page 56

Page 57

Page 58

If you've noticed an error in this article please click here to report it so we can fix it.

A Further Instalment of Our Article Dealing with the Various Aspects of Design in Both Goods and Passenger Vehicles. The Author Deals in this Section with Factors Affecting Road worthiness

IN the first two instalments of this series we have discussed in broad terms the pros and cons of various types of engine and the general trend of chassis-frame design. We will now consider the factors of comfort, safety and ease of control of both goods and passenger vehicles. These factors are largely governed by the form of suspension,, the effectiveness of the brakes and the type of steering mechanism employed, all such features being closely allied one to another; in other words, they combine to render a vehicle roadworthy or otherwise.

Now, it can be said with confidence that the characteristic of roadworthiness is probably the most important item to be considered by any engineer in charge of automobile design and where public services are concerned the importance is emphasized to a marked extent.

A vehicle capable of high speeds is quite unsafe and consequently useless if badly sprung. It follows, therefore, that (owing to bad springing) the steering qualities will be of an undesirable nature, whilst it is known that really good brakes are only effective when the road-holding characteristics of a vehicle are also good. these constituting a quality which a badly sprung vehicle cannot be expected to possess. It will then be E42 seen that the subjects of suspension, braking and steering must be dealt with conjointly.

The problem of suspension is one to which many issues of The Commercial Motor could be devoted without exhausting all the possibilities of investigation from various angles. It is a subject which many engineers of brilliant achievements have studied closely, but still the laminated leaf-spring holds sway, despite its origin (so we are told) on the later.models of the Pharaohs' chariots. From this it May be deducted that there are many advantages pcissessed. by leaf springs which are peculiar to the type and 'these

advantages, when taken as a counterbalance to the disadvantages, suffice to make other systems not worth while.

For commercial work, the semi-elliptic formation of the leaves is almost universally employed and is likely to be for some considerable time. Even in the ease of the bogie suspension of six-wheelers the springs are still generally of semi-elliptic shape, although sometimes inverted from the normal arrangement; the action, however, is entirely different, because the axles are located at the ends of the leaves with the dummy axle in the middle, whilst in the normal form of suspension with semi-elliptic leaves the axle is coupled to the springs at the centre.

The foregoing sounds a somewhat unnecessary statement, but in fact it is rather important, as will be gathered by a little examination of the functions of the two types. In the case of the normal semi-elliptic formation the load of the vehicle (when carried on four wheels) is taken at eight points, all of which are set. well apart, there being 3 ft. to 5 ft. between each pair of spring anchorages.

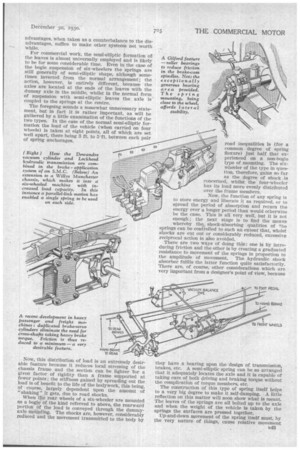

Now, this distribution of load is an extremely desirable feature because it reduces local stressing of the chassis frame and the section can be lighter for a given factor of rigidity than a frame supported at fewer points ; the stiffness gained by spreading• out the load is of benefit to the life of the bodywork, this being, of course, largely dependent upon the amount of "shaking" it gets, due to road shocks.

When the rear wheels of a six-wheeler are mounted as a bogie of the kind referred to above, the rearward portion of the load is conveyed through the dummyaxle mai:eating. The shocks are, however, considerably reduced and the movement transmitted to the body by road inequalities is (for a common degree of spring flexure) just half that experienced on a non-bogie type of mounting. The sixwheeler of the type in question, therefore, gains so far as the degree of shock is concerned, whilst the four-wbeeler has its load more evenly distributed over the frame members.

Now, the function of any spring is to store energy and liberate it as required, or to spread the period of absorption and return the energy over a longer period than would otherwise be the case. This is all very well, but it is not enough; the next stage is to find the means whereby the,, shock-absorbing qualities of the springs can be controlled to such an extent that, whilst shocks are cut out or considerably reduced, excessive reciprocal action is also avoided.

There are two ways of doing this : one is by introducing friction and the other is by creating a graduated resistance to movement of the springs in proportion to the amplitude of movement. The hydraulic shock absorber fulfils the latter function quite satisfactorily. There are, of course, other considerations which are very important from a designer's point of view, because they have a bearing upon the design of transmission, brakes, etc. A semi-elliptic spring can be so arranged that it adequately locates the axle and it is capable of taking care of both driving and braking torque without the complication of torque members, etc.

The construction of this type of spring itself helps to a very big degree to make it self-damping. A little reflection on this matter will soon show what is meant. The leaves of the springs are all bolted up to the axle and when the weight of the vehicle is taken by the springs the sarfaces are pressed together.

Up-and-down movement of the spring itself must, by the very nature of things, cause relative movement n43 between the plates. Consequently, friction must occur all the time. This friction is, in effect, a damper, but its use is not entirely satisfactory.

It will be appreciated, therefore, that the correct amount of damping to suit the spring strength is essential if the vehicle is to be well sprung, so the frictional area must be carefully graded to suit the conditions of loading. The amount of internal friction can, of course, be determined very largely by the quantity of leaves employed. The number of leaves may be varied, their thickness being accOrdingly altered, the surface over which friction occurs during spring movements being a matter of the number of plates. There may be

20 leaves in. thick or 10 leaves in. thick and so i forth.

There is, however, another factor that comes into the subject. The "amount" of friction varies with the state of the surfaces of the .plates in contact with one another ; consequently, springing is likely to become harsher as the plates rust. Now in modern machines this factor is being appreciated ; the internal friction of the springs themselves is kept at a low figure and an extraneous damping effect is often introduced which is capable of variation over a fairly wide range.

On several up-to-date designs, especially of lighter vehicles, variable frictional or hydraulic dampers are aandardized fitments.

There is a tendency nowadays on the part of pleasurecar designers to make provision for varying the damping' effect from the driver's seat, and any experienced motorist will testify to the great advantages possessed by such an arrangement. What could be more useful and beneficial to a commercial vehicle where the conditions of loading vary so enormously?

A bus, for example; when lightly loaded and rtinning comparatively slowly through a town, would be far more comfortable if the damping effect could be reduced, but when once clear of traffic and on its way to a suburb (with perhaps a full load) the damping effect would have to be increased.

As has been mentioned earlier in this series, chassis manufacturers have done all they can to render the "mechanics" of the chassis structure as well adapted to road conditions as possible; thus the springs themselves are located close to the wheels, where they are best able to deal with any tendency towards rolling. Another line of thought which has recently been developed is the provision of an auxiliary " spring " to take care of small shocks of high frequency.

One of these developments—the Gruss air spring-has been used fairly extensively in America and is fitted to several British chassis.

The high speeds of which modern passenger and goods vehicles are capable, combined with the evolution of front-wheel brakes and giant pneumatic tyres, have greatly complicated the suspension of the fronts of vehicles. Axles and springs nowadays have to deal with heavy braking torque, and, by virtue of the forward position for the driver, the suspension has to be B44 soft enough to allow of reasonably comfortable travel.

If the springs be sufficiently flexible to allow of fairly large up-and-down movements steering troubles start to manifest themselves, with the result that excmsive kick is experienced through the steering wheel and all steering joints are heavily loaded. A rather mice balance has to be struck in order to obtain the best relation between spring strength, damping effect and a deflection in the walls of the tyres (this last-mentioned feature, of course, relates to tyre pressures).

As regards brake equipment, in this section of our article we are concerned chiefly with the hook-up of the brake gear.

To bring a vehicle weighing 12 tons or more to rest in a short distance on the level and to cause deceleration on really steep single-figure gradients are matters requiring great effort, and unless the leverages are enormous (and almost impracticable) the physical effort of man is insufficient.

Servo motors have, for a long time, been standardized equipment on most of our leading makes of vehicle, but so great is the torque to be transmitted from one side of the chassis to the other that certain manufacturers have deemed it necessary to duplicate the servo action and use one instrument for applying the front and rear brakes on each side of the chassis.

One of the easiest methods of distributing the load from the driver's pedal to the brake shoes is by hydraulic pressure, the Lockheed system being perhaps the outstanding example of its type. In the S.M.C. six-wheeled bus chassis a Dewandre servo motor is coupled up to the pedal and connected to a Lockheed cylinder, so that the driver's effort is increased considerably before it reaches the hydraulic system.

In a mechanical hook-up it is necessary to cut out as much friction as possible, but owing to the heavy loads imposed by modern conditions this is a very difficult requirement to satisfy. With a cross-shaft subjectedto a high torque figure, torsional movement is bound to take place and, short of balancing up the length of shaft, it is well-nigh impossible to get equal braking effects on all wheels of a heavy vehicle. The dual servo and hydraulic systems seem to offer a way out.

Great advances have been made recently in the manner in which the final rods in a mechanical connection are arranged. It is most important for the axle movements, due to spring flexure, to be alloyed for in the brake-operating mechanism. It is obvious that one half of the spring forms a radius arm about which the axle swings, and if the brake rod itself is not controlled from a point in close proximity to the spring pins, the shoes will bt applied with varying pressures according to the vertical position of the ale in relation to the frame. With a hydraulic mechanism this difficulty does not arise.

(To be continued.)