Volvo increase power of rhd FBI

Page 36

Page 37

If you've noticed an error in this article please click here to report it so we can fix it.

Latest version has exhaust-pressure regulator for better light-load running by Trevor Longcroft

FROM September all right -hand-drive Volvo F88 models will be fitted with an uprated version of the currently specified Volvo TD100A engine. Called the TD100B, the new power unit has been designed for the F88 as a more economically produced alternative to converting the F89 to rhd. Vehicles fitted with the new engines will replace the current models, which will be phased out during the latter half of this year.

Power output from the 10-litre engine has been boosted by over 26 per cent (net installed BS AU 141a) from 172 kW (230bhp) at 2,200rpm to 217kW (191bhp) at 2,400rpm; peak torque is increased from 885.5Nm (6,631bft) to 1,040Nm (761bft) and occurs 100rpm earlier at 1,300rpm. So apart from increased power Volvo has stretched the engines working speed range by 30Orpm.

Although the engine's exterior dimensions, bore and stroke are unaltered, a number of changes have been made. The most significant of these is the reduction of compression ratio from 15 to 12.5 to 1. Piston clearance remains unchanged, but combustion chamber volume is increased. The lower compression ratio has necessitated the specification of an induction air heater, located between the turbocharger and inlet manifold; and an exhaust pressure regulator for engine starting and efficient light-load running.

Additional engine load

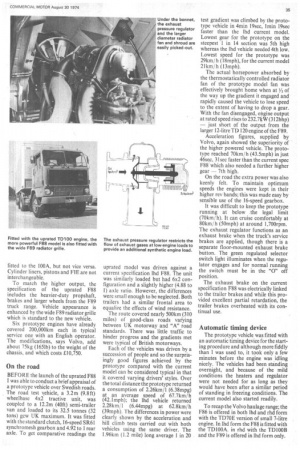

The regulator, which is also fitted to the TD7OD and E engines of the F86 truck range, provides an additional and synthetic engine load at light load conditions. When engaged, it restricts the flow of exhaust gases in the manifold; and increases back pressure and thus combustion temperature to give more efficient combustion for a cleaner exhaust and smooth running.

When running on the road, the regulator engages automatically as engine load conditions dictate, but a two-stage "high", and "low" switch in the cab is used by the driver for starting a cold engine or for light load running, say when the engine is driving auxiliary equipment only. The "high" position is used only for starting, and "low" can be selected for a quick get-away immediately after the engine has fired. An improved specification Holset turbocharger is also fitted.

On paper the starting procedure for a cold engine looks complicated and involves sensible use of both the heater and the exhaust pressure regulator. The engine can be started without the heaters, but long cranking periods will be required, and smoke and misfire can occur until the engine reaches working temperature.

All the engine start controls are on the ignition key, which must be held in the heat position for about 50 sec before and between 20-60 sec after the engine has fired. And although an automatic timing device is presently being tested, on early models it will be up to the driver to clock and check each, period if dirty exhaust and misfire are to be avoided.

Further design changes have been made to the engine cooling system. Cylinder liners have a corrugated external wall to increase the exterior cooling surface area. The larger 560mm (22in) diameter thermostatically controlled fan from the F89 is included in the engine specification as is a fan shroud to optimize air-flow characteristics. The waterpump has a different pulley for the correct fan speed and all the engine thermostats are set to 81° C.

The large capacity oil cooler from the TD120 engine is standard to the TD100B and the pistons now have only three rings instead of four. The rings, two compression and one oil scraper, are chrome plated and the wall pressure of the oil ring has been reduced to improve cylinder lubrication. The top ring has also been lowered from the hot piston crown area.

At the bottom end, the crankshaft has been strengthened by thicker webs and a higher efficiency vibration camper is fitted. At the top end, camshaft lubrication has been improved and the valve opening times have been changed to give a greater valve overlap. Valve clearances are the same as those for the TD100A engine.

Improved heat resistance valve seats are set in the cylinder head and new valve collets are specified to cope with the higher engine speeds. Exhaust manifold fixing is made simpler by doing away with gaskets and using three bolts.

FIE changes include larger diameter plungers and new nozzles for a higher rate of fuel injection without altering the injection period.

The crankshaft from the 100B can be fitted to the 100A, but not vice versa. Cylinder liners, pistons and FIE are not interchangeable.

To match the higher output, the specification of the uprated F88 includes the heavier-duty propshaft, brakes and larger wheels from the F89 truck range. Vehicle appearance is enhanced by the wide F89 radiator grille which is standard to the new vehicle.

Six prototype engines have already covered 200,000km each in typical service one with an English operator. The modifications, says Volvo, add about 75k g (1651b) to the weight of the chassis, and which costs £10,750.

On the road

BEFORE the launch of the uprated F88 I was able to conduct a brief appraisal of a prototype vehicle over Swedish roads. The road test v,ehicle, a 3.2m (9.8ft) wheelbase 4x2 tractive unit, was coupled to a 12.2m (40ft) semi-trailer van and loaded to its 32.5 tonnes (32 tons) gcw UK maximum. It was fitted with the standard clutch, 16-speed 5IZ61 synchromesh gearbox and 4.92 to 1 rear axle, To get comparative readings the uprated model was driven against a current specification lhd F88. The unit was similarly loaded but had 6x2 configuration and a slightly higher (4.88 to I) axle ratio. However, the differences were small enough to be neglected. Both trailers had a similar frontal area to equalize the effects of wind resistance.

The route covered nearly 500km (310 miles) of good-class roads vaiying between UK motorway and "A" road standards. There was little traffic to hinder progress and the gradients met were typical of British motorways.

Each of the vehicles was driven by a succession of people and so the surprisingly good figures achieved by the prototype compared with the current model can be considered typical in that it covered varying drivers' styles. Over the total distance the prototype returned a consumption of 2.26km/1 (6.38mpg) at an average weed of 67.7km /h (42.1mph); the lhd vehicle returned 2.28km/1 (6.44mpg) at 62.8km / h (39mph). The differences in power were clearly shown by the acceleration and hill climb tests carried out with both vehicles using the same driver. The 1.96km (1.2 mile) long average 1 in 20 test gradient was climbed by the prototype vehicle in 4min 19sec, 1 min 19sec faster than the lhd current model. Lowest gear for the prototype on the steepest 1 in 14 section was 5th high whereas the lhd vehicle needed 4th low. Lowest speed for the prototype was 29km/ h (18mph), for the current model 21km/h (I3mph).

The actual horsepower absorbed by the thermostatically controlled radiator fan of the prototype model fan was effectively brought home when at IA of the way up the gradient it engaged and rapidly caused the vehicle to lose speed to the extent of having to drop a gear. With the fan disengaged, engine output at rated speed rises to 232.7kW (312bhp) — just short of the output from the larger 12-litre TD 120 engine of the F89.

Acceleration figures, supplied by Volvo, again showed the superiority of the higher powered vehicle. The prototype reached 70km/ h (43.5mph) in just 46sec, 31sec faster than the current spec F88 which also needed a further higher gear 7th high.

On the road the extra power was also keenly felt. To maintain optimum speeds the engines were kept in their higher rev bands; this was made easy by sensible use of the 16-speed gearbox.

It was difficult to keep the prototype running at below the legal limit (70km/ h). It can cruise comfortably at 80km/ h (50mph) at around 1,700rpm. The exhaust regulator functions as an exhaust brake when the truck's service brakes are applied, though there is a separate floor-mounted exhaust brake button. The green regulated selector switch light illuminates when the regulator engages and for normal running the switch must be in the "0" off position.

The exhaust brake on the current specification F88 was electrically linked to the trailer brakes and while this provided excellent partial retardation, the trailer brakes overheated with its continual use.

Automatic timing device

The prototype vehicle was fitted with an automatic timing device for the starting procedure and although more fiddly than I was used to, it took only a few minutes before the engine was .idling nicely. The vehicles had been standing overnight, and because of the mild conditions the heaters and regulator were not needed for as long as they would have been after a similar period of standing in freezing conditions. The current model also started readily.

To recap the Volvo haulage range; the F86 is offered in both lhd and rhd form with the TD7OE version of small 7-litre engine. In lhd form the F88 is fitted with the TD100A. in rhd with the TD100B and the F89 is offered in lhd form only.