Permitting

Page 59

Page 60

If you've noticed an error in this article please click here to report it so we can fix it.

HIGH COMPRESSION

with

LOW-GRADE FUELS TH'problem of how to suppress detonation is one of the most urgent of those which confront the designers of commercial-vehicle engines at the present time; this is because detonation is the real (although often unsuspected) cause of much rough running and trouble with valves and pistons, in addition to producing the familiar audible knocking when an engine is particularly hot or is in need of decarbonization.

Equally important is the wellknown fact that, although power out

put and economy both improve when the compression is increased, the pressure which can actually be employed in practice is at present severely limited by the liability, to detonation on ordinary, commercial patrols., Thus, there are many engines running nowadays on compression ratios of 4i to 1 which would give much better results were it possible to raise the ratio by 50 per cent, without producing a knock.

For these reasons we regard the new system which has been developed by Mr. W. A. Whatmough, B.Sc., F.I.C., M.I.A.E., and Mr. H. S. Hewitt, of the Automotive Engineer ing Co., Ltd., as being of first-class importance, owing to the way in which it promotes smooth running and enables a high compression ratio to be employed without the slightest sign of detonation. Indeed, in a car which we tested and which had been converted to the Whatniough system, the engine was much more smooth and flexible than is usual, despite a compression ratio of 6 to 1 and the fact that the fuel was the poorest No 3 grade which our,representative could purchase.

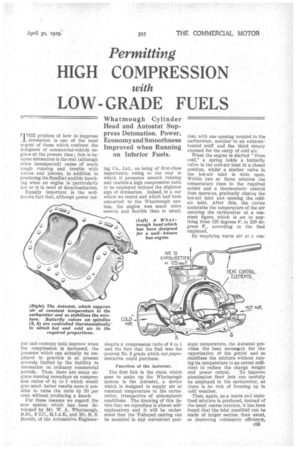

Function of the Autostat, The first link In the chain which goes to make -up the Whatmough system is the Autostat, a device which is designed to supply air at constant temperature to the carburetter, irrespective of atmospheric conditions. The drawing a this device that we reproduce is almost selfexplanatory and it will be understood that the T-shaped casting can be mounted in any convenient post tion, with one opening coupled to the carburetter, another to an exhaustheated muff and the third simOlY exposed for the entry of cold air.

When the engine is started " from cold," a spring holds a butterfly valve in the cold-air inlet in a closed position, whilst a similar valve in the hot-air inlet is wide open. Within two or three minutes the temperature rises to the required extent and a thermostatic control then operates, gradually closing the hot-air inlet and opening the coldair inlet. After this, the device maintains the temperature of the air entering the carburetter at a constant figure, which is set to anything from 125 degrees F. to 150 degrees F., according to the fuel employed.

By supplying warm air at i con

stant temperature, the Autostat provides the heat necessary for the vaporization of the p et r ol and so stabilizes the raliture without raising Its temperature to an extent stiffident to reduce the charge weight and power output. • To improve atomization finer jets can usefully be employed in the carburetter, as there is no risk of freezing up in

cold weather. . .

Then, again, as a warm and stabilized mixture is produced, instead of the usual coarse mixture, it has been found .that the inlet manifold can be made of larger section, than usual, so improving volumetric efficiency. It will be realized that in most engines the section of the manifold is purposely kept small, so as to maintain a high mixture speed and to prevent the deposition of the liquid fuel. This actually throttles the engine and so reduces the power output at the higher speeds.

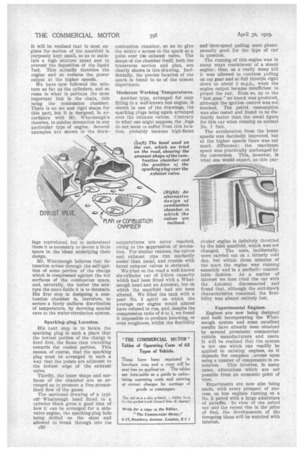

We have now followed the mix-, ture as far as the cylinders, and so come to what is perhaps the most important link in the chain, this being the combustion chamber. There is no set and rigid shape for this part, but it is designed, in accordance with Mr. Whatmough's theories, to subdue detonation in any particular type of engine. Several examples are shown in the draw ings reproduced, but to understand these it is necessary to devote a little space to the ideas underlying their design.

Mr. Whatmough believes that detonation arises through the self-ignition of some portion of the charge which is compressed against the hot surfaces of the combustion space, and, naturally, the hotter the mixture the more liable it is to detonate. His first step in designing a combustion chamber is, therefore, to secure a fairly uniform distribution of temperature, by devoting special care to the water-circulation system.

Sparking-plug Location.

His next step is to locate the sparking plug in such a place that the hottest portion of the charge is fired first, the flame then travelling towards the coolest portion. This means, of course, that the sparking plug must be arranged in such a nay that the points are adjacent to the hottest edge of the exhaust valve.

Thirdly, the inner shape and surfaces of the chamber are so arranged as to promote a free streamlined flow of the gases.

The sectioned drawing of a typical Whatmough head fitted to a cylinder block gives a good idea of how it can be arranged for a sidevalve engine, the sparking-plug hole being drilled on the slant and allowed to break through into the c30

combustion chamber, so as to—give the mixtu: e access to the spark at a point over Use exhaust valve. The shape of the chamber itself, both the transverse section and plan, are clearly shown in this drawing. Incidentally, the precise location of the spark is found to be of the utmost importance.

Moderate Working Temperatures.

Another type, arranged for easy fitting to a well-known bus engine, is shown in one of the drawings, the sparking plugs being again arranged over the exhaust valves. Contrary to what one might suppose, the olugs do not seem to suffer from this location, probably because high-flame temperatures are never reached, owing to the ?oppression of detonation. For similar reasons, the valves and exhaust pipe run markedly cooler than usual, and trouble with burnt exhaust valves is obviated.

We tried on the road a well-known six-cylinder car of 2-litre capacity which had been fitted with a Whatmough head and an Autostat, but on which the manifold had not been altered. We filled the tank with a poor No. 3 spirit on which the average car engine would almost have refused to run, and, despite the compression ratio of 6 to 1, we found it impossible to produce knocking, or even roughness, whilst the flexibility aftd-Slow-speed pulling were phenomenally good for the type of car in question.

The running of this engine was in many ways reminiscent of a steam engine; thus, on a really steep hill it was allowed to continue pulling on top gear and at full throttle right down to about 2 m.p.h., when the engine output became insufficient to propel the car. Even so, up to the "last gasp" no knock was produced, although the ignition control was not touched. The petrol -minsumption was also tested and found to be distinctly better than the usual figure for this car when running on normal No. 1 fuel.

The acceleration from the lower speeds was decidedly improved, hut at the higher speeds there was not much difference; the maximum speed was practically unchanged by the conversion. This, however, is what one would expect, as this par ticular engine is definitely throttled by the inlet manifold, which was not changed. The tests, incidentally, were carried out on a bitterly cold day, but within three minutes of the start the engine was running smoothly and in a perfectl ,r controllable fashion. As a matter of interest we then tried the car with the Autostat disconnected and fcund that, although the anti-knock characteristics remained, the flexibility was almost entirely lost.

Experimental Engines.

Engines are now being designed and built incorporating the Whatmough system and some excellent results have already been obtained by several prominent commercialvehicle manufacturers and users. It will be realized that the system is not one which can readily be applied to existing engines, as it depends for complete _Access upon using a number of components in co relation. This involves, in many eases, alterations which are not possible from an economic point of view.

Experiments are now also being made, with every prospect of success, on bus engines running on a No. 3 petrol with a large admixture of paraffin. In view of the petrol tax and the recent rise in the price of fuel, the developments of the foregoing ideas will be watched with interest.