:oden to ;how new Jump truck Ind semi-auto chassis

Page 62

Page 67

If you've noticed an error in this article please click here to report it so we can fix it.

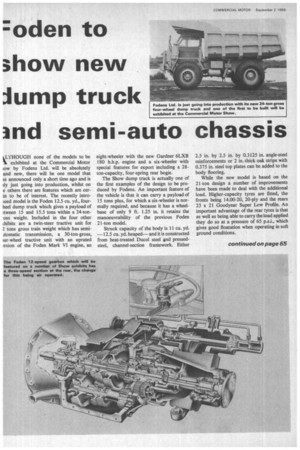

LLTHOUGH none of the models to be %. exhibited at the Commercial Motor Low by Fodens Ltd. will be absolutely and new, there will be one model that Is announced only a short time ago and is ily just going into production, whilst on e others there are features which are cerin to be of interest. The recently introiced model is the Foden 12.5 cu. yd., fourheel dump truck which gives a payload of :tween 15 and 15.5 tons within a 24-tonoss weight. Included in the four other thibits are a twin-steer tractive unit for 2 tons gross train weight which has seminomatic transmission, a 30-ton-gross, lur-wheel tractive unit with an uprated !.rsion of the Foden Mark VI engine, an eight-wheeler with the new Gardner 6LXB 180 b.h.p. engine and a six-wheeler with special features for export including a 28ton-capacity, four-spring rear bogie.

The Show dump truck is actually one of the first examples of the design to be produced by Fodens. An important feature of the vehicle is that it can carry a payload of 15 tons plus, for which a six-wheeler is normally required, and because it has a wheelbase of only 9 ft. 1.25 in. it retains the manoeuvrability of the previous Foden 21-ton model.

Struck capacity of the body is 11 cu. yd. —12.5 cu. yd. heaped— and it is constructed from heat-treated Ducol steel and pressedsteel, channel-section framework. Either 2.5 in. by 2.5 in. by 0.3125 in. angle-steel reinforcements or 2 in.-thick oak strips with 0.375 in. steel top plates can be added to the body flooring.

While the new model is based on the 21-ton design a number of improvements have been made to deal with the additional load. Higher-capacity tyres are fitted, the fronts being 14.00-20, 20-ply and the rears 23 x 21 Goodyear Super Low Profile. An important advantage of the rear tyres is that as well as being able to carry the load applied they do so at a pressure of 65 psi., which gives good floatation when operating in soft ground conditions. Power steering is employed and in order to increase the payload the centre of gravity of the load has had to be moved forward, through the body design. The front axle, which is plated for 8 tons, is now fitted with Aeon rubber helper springs. The rear springs are a new design and are carried in frame brackets which have floating shackles as used on Foden eight-wheelers. This has been done to increase the capacity of the bearing areas.

Flitch plates Basic frame size remains at 12 in. by 3 in. by 0.375 in. and there is a flitch plate in each main member extending from the rear end to a point in front of the front-spring rear brackets. The rear axle is based on the latest Foden pressed-steel, double-reduction unit with stiffening ribs added to deal with the 16-ton load it carries. The standard engine is the Gardner 6LX and the gearbox a Foden 12-speed underdrive unit.

Most interesting of the other exhibits will be the DAL 6/32, twin-steer tractive unit which has a 12 ft. 6 in. wheelbase and is designed to operate at 32 tons g.t.w. The engine is a Leyland 0.680 diesel (200 b.h.p.) and the transmission is through a fluid clutch and a Self-Changing Gears RV.38, five-speed, semi-automatic gearbox.

The braking system includes a transmission-type handbrake, and operation of the lever also brings in the secondary system which applies air to the triple-diaphragm units at both front axles and the auxiliary connection for the semi-trailer. The service brakes are divided between the front axles and the driving axle and the tractive unit is also fitted with a Clayton Dewandre loadsensing valve on the driving axle which reduces the braking effort on the axle proportionally to the load on it.

Another interesting fitting is a Clayton Dewandre combined condenser unit and drain valve which automatically keeps the System free of moisture. This type of unit is becoming increasingly popular.

The tyres shown on the vehicle are Michelin 10.00-22.5 tubeless on the front and 18 x 19.5 low profiles from the same maker at the rear. The 10.00-22.5 are the lightest wheel combination available to replace 9.00-20 tyres; they are 14 lb. each lighter than Michelin X 19.00-20 and 27 lb. lighter than 9.00-20 textiles.

The four-wheel tractive unit for 30 tons to be shown by Fodens has a Foden Mk. VI two-stroke diesel engine modified to produce 180 b.h.p. at 2,250 r.p.m. instead of the previous 175 b.h.p. at 2,200 r.p.m. A torsional vibration damper is fitted to allow this and the only other modification is the use of a new three-belt fan drive; a six-row radiator is used on the chassis. The engine drives through a Foden 12-speed overdrive gearbox.

Another feature of the Show model will be a modified version of the reinforced plastics tilt cab used by the company. Main improvements are a stronger framework, a better driver's "pan", slam-type door locks and a higher windscreen top level. The design of cab mounting has been modified and CAV dual headlamps replace the previous rectangular Cibie Units. The design of instrument -panel has been improved and this is now mounted as a binnacle on the steering column and in conjunction with a different-design steering wheel the instruments are easier to read. The switches are also easier to reach. The general shape of the cab is little changed, but the shell is now moulded in one piece to give increased rigidity and the front grille is detachable to give better access to the radiator for servicing.

Load-sensing valve The brake system again incorporates a Clayton Dewandre load-sensing valve, but there is a separate control for the secondarybrake system—a hand-control valve on the steering column—and this feeds air to the triple diaphragms on the front axle and the semi-trailer auxiliary connection; till handbrake operates only the drum-typi transmission brake.

Apart from the use of the new Gardne 6LXB engine, the eight-wheeler to be show' by Fodens is typical of the standard rang+ of four-axle, 24-ton gross tippers made the company. The current 12-speed over drive gearbox is used, but the higher torqui output of the Gardner has made it neces sary to use a 17 in.-diameter clutch. Thi! unit has been designed to give improver ventilation in order to improve cooling an life. Air circulation is provided round hod the flywheel side of the clutch and tin pressure-plate side and also through slots ir the linings. Braking meets the latest regula tions with triple-diaphragm chambers at tin front axles for secondary braking.

Yet another engine is featured in the fina exhibit, a 6 x 4 chassis aimed chiefly at export markets. The power unit is a Cummins NHE, 210 b.h.p. engine and this drives through a 12-speed underdrive gearbox. The model is designed for operation with a drawbar trailer or semi-trailer and has an 8-ton front axle and 28-ton-capacity, fourspring rear bogie. The rear axles are fitted with worm-and-wheel primary reduction and secondary reduction in the hubs. The latter is through bevel wheel and pinion gearing and by a simple operation the hub reduction can be engaged or disengaged. This means that when the vehicle is used with very heavy loads the axle reduction can be twice what it is when running empty. The primary reduction in the Show chassis will be 5.75 to 1.

The cab will have a double roof and another overseas fitting also to be shown on the vehicle is a front-frame extension and wrap-round bumper which may be of interest to some English operators wishing to reduce cab damage. The feature can be fitted as an extra to all vehicles with a Foden fixed cab.

A.J.W.