Ramieifs First Forward-con " Artie "

Page 52

Page 53

Page 54

If you've noticed an error in this article please click here to report it so we can fix it.

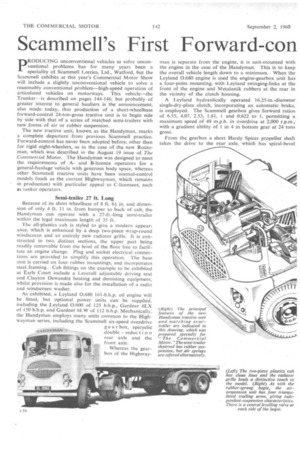

pRODUCING unconventional vehicles to solve unconventional problems has for many years been a speciality of Scammell Lorries, Ltd., Watford, but the Scammell exhibits at this year's Commercial Motor Show will include a slightly unconventional vehicle to solve a reasonably conventional problem—high-speed operation of articulated vehicles on motorways. This vehicle—the Trunker—is described on pages 144-146, but probably of greater interest to general hauliers is the announcement, also made today, that production of a short-wheelbase forward-control 24-ton-gross tractive unit is to begin side by side with that of a series of matched semi-trailers with new forms of air or rubber suspension.

The new tractive unit, known as the Handyman, marks a complete departure from previous Scammell practice. Forward-control has never been adopted before, other than for rigid eight-wheelers, as in the case of the new Routeman, which was described in the August 19 issue of The Commercial Motor. The Handyman was designed to meet the requirements of Aand B-licence operators for a general-haulage vehicle with generous body space, whereas other Scammell tractive units have been normal-control models (such as the current Highwayman, which remains in production) with particular appeal to C-licensees, such Is tanker operators.

Semi-trailer 27 ft. Long

Because of its short wheelbase of 8 ft. 61 in. and dimension of only 4 ft. 11 in. from bumper to back of cab, the Handyman can operate with a 27-ft.-long semi-trailer within the legal maximum length of 35 ft.

The all-plastics cab is styled to give a modern appearance, which is enhanced by a deep two-piece wrap-round windscreen and an entirely new radiator grille. It is constructed in two distinct sections, the upper part being readily removable from the level of the floor line to facilitate an engine change. Plug and socket electrical connections are provided to simplify this operation. The base unit is carried on four rubber mountings, and incorporates steel framing. Cab fittings on the example to be exhibited at Earls Court include a Leveroll adjustable driving seat and Clayton Dewandre heating and demisting equipmen t, whilst provision is made also for the installation of a radio and windscreen washer.

As exhibited, a Leyland 0.680 161-b.h.p. oil engine will be fitted, hut optional power units can be supplied, including the Leyland 0.600 of 125 b.h.p., Gardner 6LX of 150 b.h.p. and Gardner 6LW of 112 b.h.p. Mechanically, the Handyman employs many units common to the Highwayman series, including the Scammell six-speed overdrive gear box, epicyclic

R.A1MNI . , double reduc tion

rear axle and the front axle.

Whereas the gearbox of the Highway

man is separate from the engine, it is unit-mounted with the engine in the case of the Handyman. This is to keep the overall vehicle length down to a minimum. When the Leyland 0.680 engine is used the engine-gearbox unit has a four-point mounting, with Leyland swinging-links at the front of the engine and Metalastik rubbers at the rear in the vicinity of the clutch housing.

A Leyland hydraulically operated 16.25-M.-diameter single-dry-plate clutch, incorporating an automatic brake, is employed. The Scammell gearbox gives forward ratios of 6.55, 4.07, 2.53, 1.61, 1 and 0.622 to 1, permitting a maximum speed of 49 m.p.h. in overdrive at 2,000 r.p.m., with a gradient ability of 1 in 4 in bottom gear at 24 tons gross.

From the gearbox a short Hardy Spicer propeller shaft takes the drive to the rear axle, which has spiral-bevel primary reduction gearing and epicyclic secondary reduction gears, giving a standard overall ratio of 7.78 to 1, with five opti anal ratios. The front axle has tapered-roller thrust bearings and Thompson selfadjusting ball joints. At both axles semi-elliptic Srings are used, those at the rear being triple-rate units, whilst the suspension is controlled by Woodhead-Monroe telescopic dampers. Thus, despite the sliort wheelbase, the ride should be acceptable even when unladen.

The chassis-frame side members are + in thick and have

a maximum depth of 8 in., with flanges. Four crossmembers are bolted in position. All but the leading member are of tubular section, the first being a pressing. fONSAFRCLM.) MOTOR

Seaintnell heavy-duty automatic coupling gear, with air-pressure-operated release mechanism controllable from the driving seat, is to be exhibited, but Spherub or S.M.M.T.JS.A.E. fifth-wheel coupling gears are offered.

Girling 16-in. by 3-in, wedge-operated brakes are employed at the front axle, whilst at the rear Scammell 17-in. by 5-in, units are used. The front brakes have operating cylinders mounted directly on the back plates, and at the rear axle the cylinders are mounted on the frame. Power for the air-pressure system is produced by a Clayton Dewandre twin-cylinderecl air-cooled compressor working at 80 p.s.i.' for the braking system and 130 psi. for the tyre inflator. The total tractive-unit brake frictional area is 418 sq. in., and a hand reaction valve is fitted in the cab for independent control of the semi-trailer brakes.

Interchangeable Tyres

Marles cam-and-double-roller steering gear is specified.

with a 20-in.-diameter wheel. The standard tyres are 10.00-20-in. (14-ply); this size is fitted also to the wheels of the standard matching semi-trailer. A single 55-gal. fuel tank is supplied as standard, but twin tanks can be fitted. The electrical system is 24v. A paired headlamp system can be specified, and standard electrical equipment includes flashing direction indicators and twin Windtone horns.

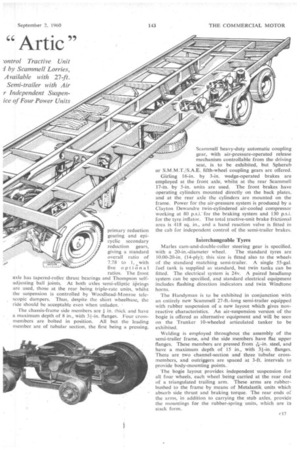

The Handyman is to be exhibited in conjunction with an entirely new Searnmell 27-ft.-long semi-trailer equipped with rubber suspension of a new layout which gives nonreactive characteristics. An air-suspension version of the bogie is offered as alternative equipment and will be seen on the Trunker 10-wheeled articulated tanker to be exhibited.

Welding is employed throughout the assembly of the semi-trailer frame, and the side members have flat upper flanges. These members are pressed from 1'w-in. steel, and have a maximum depth of 15 in., with 31-in. flanges. There are two channel-seetiOn and three tubular crossmembers, and outriggers are spaced at 3-ft. intervals to provide body-mounting points.

The bogie layout provides independent suspension for all four wheels, each wheel being carried at the rear end of a triangulated trailing arm. These arms are rubberhushed to the frame by means of Metalastik units which absorb side thrust and braking torque. The rear ends of the arms, in addition to carrying the stub axles, provide the mountings for the rubber-spring units, which are in stack form. Although independently mounted, the wheels on each side of the semi-trailer are linked by beams centrally pivoted to the frame at the mounting brackets for the rear arms. The beams are connected to the rubber stacks by light linkages, and have the effect of distributing the bogie loading evenly between the front and rear wheels. Addii ionally, in conjunction with the trailing arms, they cut out the internal reactive forces set up when braking, thus keeping all the tyres in contact with the ground and so giving maximum braking adhesion.

Metalastik rubber bushes are used for the trunnion mountings for the longitudinal beams, and oilless fabric bushes are employed at the tops of the rubber-spring stacks and at the balance-beam links. Apart from periodic attention to the wheel hubs, no lubrication of the bogie is required. The rubber springs are self-damping and they act in compression, so giving progressive suspension characteristics. Smooth, shock-free riding should be assured, both laden and unladen.

4-0

essential differ

+0 60

Foe•V' [(M.P.H.)] R FTC—

ence being that the rubber stacks are replaced by Firestone doubleconvolution belderivation is fully described in the article lows units. This on the Trunker.

Use of independent suspension for both these bogies is a significant move towards the greater stability of an articulated vehicle. The layout reduces roll, because the spring centres are on the lines of the wheel tracks, instead of being inboard of the wheels, as with conventional bogie suspension. Furthermore, the wheels deflect constantly parallel to the chassis frame, and this helps the semi-trailer to " sit' on the road.

A further important advantage of the bogie layout concerns tank semi-trailer applications. The absence of normal axle beams running across the vehicle below frame level leaves a clear run from front to rear for pipes, thus simplifying the installation of pumping equipment.

There • is a choice of brakes with each version of this bogie. The semi-trailer coupled to the Handyman tractive unit at Earls Court will have Girling wedge-actuated units with 15.25-in.-diameter drums and 5-in.-wide linings, giving a frictional area of 592 sq. in. Alternatively, Leyland camDperated .brakes with 15.5-in.-diameter -drums and 7-in.wide linings (giving 757 sq. in. area) can be fitted.

On the exhibit the brakes are rod and cable operated from an air servo on the tractive unit, as is usual with the Scammell automatic coupling gear. When cam brakes are fitted, diaphragm-type servos are mounted on the trailing arms.

The complete outfit to be shown will have an overall length of 34 ft. 111 in. and an overall width of 8 ft. The unladen weight totals 8 tons 131 cwt.

c18