British P.S.V. Production Leads the World

Page 104

Page 105

Page 106

Page 107

If you've noticed an error in this article please click here to report it so we can fix it.

Coach and Bus Makers Increase Output in 1958 in the Face of Difficulties: Exports Valued at £10.7m

Big Repeat Orders By Tom Waliterley

DURING the first months of 1958, tight money at home and import restrictions overseas made the commercial vehicle salesman's job an

unenviable one. In particular, falling traffics in passenger transport in this country, and big increases in wages and other charges, had most operators badly worried. It was clearly no time to launch tlee'-replacement projects.

Later in the year. when the national economy was stated almost miraculously to have turned a remarkably slippety corner, hire-purchase facilities became available on a scale unknown since the war and there was a temptation to indulge in something of a spending spree. The more experienced operators, however. viewed the future with caution, and thought in terms of bigger buses to carry heavy traffic, Or one-man-operated vehicles for less remunerative routes.

Overseas, the story was not dissimilar, although the marketing scope was probably wider than at home. America, long regarded as the home of easy hire-purchase facilities, felt the cold contraction of decreased produotivity earlier, and to a greater extent than her European rivals. The Commonwealth, tied almost as much to the dollar as to sterling and committed to sizeable indigenous manufacturing projects in recent years, felt obliged to reinforce its customs barriers. For the British manufacturer, the export business became steadily tougher—if more stimulating.

Figures produced by the Board of Trade and the Society of Motor Manufacturers and Traders indicate how the battle for exports went during 1958. In 1957, commercial vehicles of all kinds shipped overseas amounted to 123,283. They were valued at £87m.

Last year, the total had dropped to 112,594 units worth £82m. The industry

took a painful knock, but, in fact, by the end of the year, there were definite signs of an improvement in world trade. It is unlikely that 1959 will be a record year for commercial-vehicle producers, but the indications are that it will see a steady improvement in demand.

The passenger-vehicle section of tl industry actually increased its output i 1958, despite the difficult conditions pri vailing both at home and abroad. Tot production went up from 9,498 in 195 to 9,846. Exports, on the other ham showed a small drop, from 6,079 to 5,77 units, with a consequent decrease i revenue from £11.1m. to £10.7m.

Today, the bulk of the British expoi business concerns the supply of chass for locally built bodies. In this categor! orders for both single-deckers and doubt( deckers showed small decreases in th period. At 3,026, single-decker chass units were in much greater demand tha the double-deckers.

On the other hand, the excellence a British-built double-decker bodywork i reflected in the sales of 1,727 complete vehicles, worth £2.6m. In 1957, the figures were 1.722 and £1.8m. respettively.

In world markets where international competition is keener than ever. United Kingdom manufacturers continue to maintain their po.;ition as premier pro ;. In the nine months to September, this country built 6,816 public serabides. Western Germany, Britain's t rival, was responsible for 5,367. United States, France and Italy en them built 6,308.

• oial statistics, however, throw little light on what is going on in the ies. They serve to indicate the ; of world trade but show ig of the quality of the products are meeting the demand. Tnevitit may be many years before the ; of salesmen, designers and engino create and then meet demand are .ed in the annual figures.

of the most encouraging indica of success is the repeat order. Guy irs, Ltd., for example, have for years mtrated on Continental markets with lent results. In 1958; they supplied !et of 'Warrior, underfloOr-engined is, powered by Gardner 61ILW to U.T.I.C., old-established iners in Portugal. '

her Warriors, with .vertical engines, to Belgiurn, for De Snell Vliet. This chassis has a wheelbase of 19 ft. 3 . in. and 5.1-litre oil • engine. The body was built by • B.O.V.A. to accommodate 44 passengers. • .

Guy also delivered their first export Victory. single-deck buscoach chassis ordered by Reederij op de Lek, N.V. This model was developed ,primarily with the Continental -operator in mind and is proving popular with Dutch and Belgian Concerns:The Victory has an 18-ft. wheelbase, overall length of 36 ft. and is suitable for bodies

carrying up to 85 passengers on urban and rural routes.

The specification includes a five-speed gearbox, spiral-bevel rear axle and dualcircuit air-pressure brakes. To meet the requirements of the individual customers. several engines are available at choice, as are gearbox arrangements.

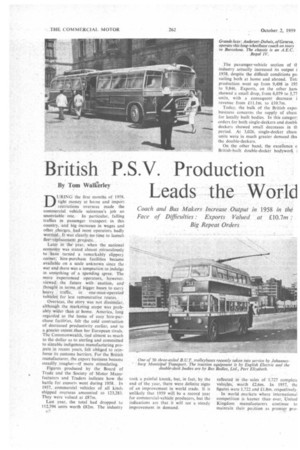

Farther afield, Guy are supplying 105passenger double-deck buses to Johannesburg municipal undertaking. These big vehicles form part of a £300,000 order for motorbuses and trolleybuses for the traitsport authority. The three-axled chassis carry bodies manufactured by Bus Bodies. Ltd., Port Elizabeth, and are 33 ft. 10+ in. long overall and 8 ft. 2+ in. wide. The oil engines supplied are Rolls-Royce 12.2litre, driving through five-speed preselector epicyclic gearboxes.

With total vehicle exports amounting to about f20m. in 1958, Leyland Motors. Ltd., and their subsidiary companies. Albion Motors, Ltd., and Scammell Lorries, Ltd., claim to be the largest single manufacturers of heavy-duty commercial vehicles in the British Empire.

In overseas markets, the company's best-seller is probably the Leyland Comet passenger chassis, large numbers of which are being manufactured in India by Ashok Leyland, Ltd. The chassis has been found to meet the requirements of operators using partly developed road systems, where the robust frame and economical 0.350 oil engine are fully appreciated. Major demands have been met from South Africa, Pakistan, New Zealand, Central Africa, Jamaica and Ceylon.

Lim. Order from Ceylon

Of orders worth nearly flm. from the Ceylon Transport Board last year, 136 concerned Comet passenger models. Most of these were supplied with MetropolitanCammell-Weymann bodies.

Nearly a third of all the passenger orders from overseas were for the Royal Tiger Worldmaster series.. This is an underfloor-engined chassis, specifically designed for the export market. A repeat order for 80 was taken from Motoimport. the Polish Government purchasing agents; the vehicles will be used for the proposed express luxury service between Warsaw and Baltic resorts.

These coaches are being supplied with 62-seat bodies by Dansk Automobil Byggeri, A.S.. Leyland's Danish associated company. A roof luggage rack is capable of carrying 14 cwt., in addition to a further 4 cwt. in the boot. Extra seats are arranged to fold over the gangway and oil-burning heaters are provided.

From Brazil came a further order for 40 Royal Tiger Worldmasters for the Empreza de Onibus Alto do Pasi, Ltda., Sao Paulo. These chassis will have aluminium stage-carriage bodies built locally by C.A.I.O. and will seat 46 passengers.

Service in the Commonwealth

During the past year, the Leyland Tiger Cub has also found ready markets in India, Denmark, New Zealand and Holland. Other sales have been made in Ghana, Portugal and Trinidad. The company have manufacturing plants. managed by their own staff and factorytrained personnel in Australia, Rhodesia and South Africa.

The progressive manufacture of the Comet is being undertaken by Ashok Leyland, Ltd., at Ennore, Madras, and assembly plants are in operation in Eire. Belgium. Denmark, Holland. New Zealand, Pakistan, Spain and Turkey.

So far as the mass-producers of lighter commercial chassis are concerned, it is G4 not possible to estimate with accuracy the proportion of their products that eventually become buses and coaches overseas. It is known, of course, that many are destined to be equipped with passenger bodies of local manufacture.

The Austin Motor Co., Ltd., for example, calculate that about 80 per cent. of their exports to Ceylon last year were so dealt with. The 5-ton chassis is particularly popular for this purpose.

The Commer Avenger forward-control passenger chassis is to be found in regular service all over the world, sometimes with a British-built body, more often with a local version. Of the former, there are examples with coachwork by Harrington in Liberia and by James Whitson in Pakistan (where they are operated by Air France). The basis for much local bodywork is the Comtner Superpoise goods chassis, but tvlulliners have also built several bodies for service in Central Africa and the Middle East.

Bedford increased their share of the export market for passenger chassis by 13 per cent. in 1958. The biggest customer was Pakistan: Australia and India were also big buyers. All these units were dispatched completely knocked down from the Dunstable factory. Other Bedford passenger vehicles were assembled abroad, some in one or other of the six General Motors overseas plants. Many were equipped with locally built bodies.

The A.E.C. works at Southall were busily completing their massive order, worth £23an., for 250 double-deckers for Teheran. This was history, indeed, not only on account of the size of the contract, but also because it introduced the double-decker to the country. As these words are written, 120 of the new vehicles are in service: the rest await an improvement in road conditions before they can be driven from the port of Khorramshahr to Teheran.

From Baghdad came an order for 140 Regent Mark V chassis with •Monocon• trol transmission. These were supplied with partially knocked-down bodies by Park Royal Vehicles, Ltd., a new development for the factory. Not only does a consignment of this kind cost much less to ship, but the assembly overseas provides welcome work for local coachbuilders.

In this case, the British factory completed the assembly of the lower saloon as far as the intermediate floor: the upper • deck was then packed into the lower saloon. The fitment of outside panels and the erection of the upper saloon are carried out in central workshops in Baghdad.

Shipments of 132 RegalMark IV chassis for Sydney commenced during the year. These, with a similar quantity of Leyland Worldmasters, were the first buses with fully automatic transmission

to be supplied to Australia. The newly formed Perth Metropolitan Transport Trust ordered 10 . Regal Mark IV bus chassis and Brisbane made inquiries for 20 Regal Mark IV and 12.Reliance.

Repeat orders were received from Johannesburg municipality for 20 Mark IV chassis of 19-ft. 6-in, wheelbase, and 60 Regent Mark V chassis of 17-ft. 6-in. wheelbase. Both are powered by 11.3-litre oil engines and have Monocontrol transmission. Bus Bodies (S.A.). Ltd., are to supply the bodies.

Other orders from the African continent came from the Benguela Railway, Luanda municipality and Rhodesia. Many African operators favour the Ranger 18-ft.-wheelbase chassis, bodied to their own requirements in local workshops.

Nearer home, the European market continued to accept a steady flow of A.E.C. coach and bus chassis. Competitive quotations have been made in Greece but here heavy duties on imported bodies and lack of adequate local factories make the market difficult. Portugal, Holland

Belgium once again provided gratifyepeat orders, many of them for cornon by bodybuilders on the spot. ;Iced what developments in 1958 be expected to bear fruit in 1959, Eric HoElands, one el the directors general manager of A.C.V. Sales, said that the increased use of c.k.d. ing was significant: the costs were r and the political angle in the .gn country, where labour was cheap

plentiful, often favoured British ,ery in this way. He added that eased attention was being paid to lug the relatively small order, which d he the bread and butter of the try,

issenger bodybuilders, such as Metroan-Cammell-Weymann, Ltd., have itained their place as leading trters in the industry. From this ern alone, more than 300 singleand ,le-deck bus bodies were shipped to 4, Jamaica, Sierra Leone, Ceylon, ugal, Nigeria and Trinidad, Promiamong the orders met was one for ouble-deck bodies on A.E.C. chassis ..isbon. These were unusual in having t entrances.

Tropical Coachwork

iree special single-deckers, based on on chassis, were supplied to the eila Bus Services, in the Sudan. The ate called for double roofs, sun visors the driver's cab, generous ventilation the large roof-racks which are essenwhere an overload of passengers and age is customary.

.C.W. also reinforced the fleet of Leyland Olympic chassisless singleers operated by Jamaica Omnibus ices, Ltd., who now have more than

'olleybuses continue to be popular -ever electricity is cheap, or where uel is expensive. British manufac-s have been meeting the need with ur and success.

'itish United Traction, Ltd., for aplc, have supplied 33 complete Le-deckers to Wellington, New Zea. These are two-axled vehicles, 33 ft. . long and 8 ft. wide. The M.C.W. es are designed for 43 seated and 21 ding passengers and have front ance and centre exit doors.

Safety Off the Wires

:•action equipment is by the English tric Co., Ltd. A feature of the air:e specification is the provision of an tional reservoir to double the normal why; there is also a special automatic :e to prevent running-on in the event trolley dewirement,

n interesting aspect of a contract for hassis for Oporto is the fact that they replace trams running over the Eiffel ge. This iron structure has been :ring damage from electrolytic action vibration for many years. The new eybuses will obviate this nuisance. .U.T. have also supplied 50 three-axled ale-deck trolicybuses to JohannesI. These vehicles, too, have English tric traction equipment, and the :hwork is by Bus Bodies. What are claimed to be the largest double-deck trolleybuses in the world are the 105-passenger vehicles built for Johannesburg by the Sunbeam Trolleybus Co., Ltd. Twenty ,of these chassis, with Bus Bodies coachwork, have been supplied.

Other overseas orders for Sunbeam have come from Colombo, Brisbane, Penang, Pretoria and Bergen. Traction equipment is supplied to meet individual requirements and may be by British Thomson-Houston, Crompton-Parkinson, General Electric or Metropolitan-Vickers.