WHAT'S BREWING?

Page 36

Page 37

Page 38

If you've noticed an error in this article please click here to report it so we can fix it.

While brewers' distribution vehicles with dramatically lower platforms are appearing: modifications to current designs are not really satisfactory. This industry's advisory committee has sent its ideal spec to II manufacturers and four bodybuilders

BREWERS do not much like offdie-peg vehicles. They prefer wherever possible to have them made to measure. Sometimes that can mean a lot of expensive cloth cutting.

That is why some vehicle and body manufacturers regard this particular group of operators as awkward customers, although such is their purchasing power that none would voice that opinion too loudly.

The brewers themselves are well aware of their individual corporate muscle. One of the reasons for forming the Brewery Transport Advisory Committee, which was first established

14 years ago, was to make more of their influence as a group.

MAC members may compete fiercely with each other selling beer or soft drinks, and even in Vehicle -performance at the annual fuel economy trials at MIRA. But each firm stands a better chance of getting the vehicle specification it wants if it can Convince the manufacturer that after it is designed and built it will be sold to many more than one brewing Company.. There are currently 21) BTAC members

responsible for in total around 50,0no vehicles, Following the uplift in maximum legal gross weight of 1983, brewers, in ore than any other single group of transport operators, spent in uch tinie and effort in determining whether they should operate at 38 tonnes and, if si I,. how best to do so with particular. regard to vehicle Safety. Now virtually ;ill the roll stability testing iind the like is over and final specifications for most brewers' 38-tonners have been decided. The emphasis is switching from trunkers to local distribution vehicles.

Sonic vehicle and body manufacturers may believe that brewers have a A Nation with lowering the platform height 01their local delivery vehicles. For many years they have been seeking ways of doing this and recently, as a direct result of continued pressure from them, some interesting new designs, like step-frame and spineback conversions, have emerged. These can lower platform height dramatically and you can see a growing number of vehicles of this type in brewers' liveries.

But there is mounting demand for a more radical change in vehicle design to satisfy die objectives spelled out by Andrew Davis. Whitbread's distribution engineer manager and BTAC project leader on this topic, in March at the .1cf AC conference.

The three objectives Davis spoke of are "Safe operation; productivity and cost effectiveness of the vehicles and drivericrew; and environmentally acceptable vehicles-.

The new urgency in demand for a local distribution vehicle which makes load handling safer and easier is linked with the imminent publication of new regulations from the Health and Sakty Executive. A consultative document on the Health and Safety (Manual Handling of Loads) Regulations is expected to be circulated early.' next year with implementations of the new law planned for 1987.

These Ilealth and Safety Regulations will be much more specific than chose of 1974, particularly in regard to maximum weight limits fur objects being handled

afld di!•4311Cc: ttley arc lifted.

At the same time as the I lealth and Safety Regulations governing the handling of loads on distribution vehicles are changing so Lou are the kinds of loads being carried in brewers' local delivery vehicles and the premises to which they are delivered. There is

growth in the so-called "take-home marketwith the result that brewers are delivering a greater percentage of their production in cans and less in kegs. And increasingly they are delivering to shops in side streets where vehicle access is more difficult than at the average pub.

Increasing competition between brewers is putting pressure on all of them to reduce their distribution costs and the cost per pack of cans or per keg delivered to the customer. One area where clearly there is potential for big cost savings is in the number of vehicle crew. It has been commonplace to see crews of three per vehicle. Now two men per vehicle is more common and it is just possible that one day, with the right vehicle, one man may be able to do the job.

At present the brewers' engineers' efforts arc largely directed at persuading vehicle manuficairers that they should move away entirely from traditional truck designs for a local delivery vehicle of the future — one which they are convinced that not only brewers would want.

There is now probably more interest than ever before being shown by manufacturers in this subject, though still the essence of their argument against such a move is the cost of a wholly new design weighed against the number they could hope to sell. BTAC has sent its ideal local delivery functional specification to 11 vehicle manuficturers and four bodybuilders.

Why cannot trucks of current design, even when substantially modified like the drop-frame or spineback rigids, do the job the brewers want? The answer is they can, but not as efficiently as they might.

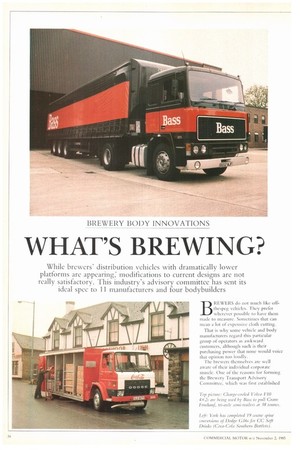

Roger Denniss, director of distribution at Bass, sums up the underlying reason for his company and others putting renewed pressure on manufacturers to produce this ideal distribution vehicle as "the growing need for improved efficiency-.

He is not a fan of drop-frame or spineback rigids. He points to disadvantages such as high initial cost,

high kerbweight, and poor turning circles. The workhorse of Bass's current local delivery fleet is a vehicle which many gelieral hauliers would consider out of the ordinary itself, the Bedford TL1630 artic.

Bass operates 745 of these, so clearly they perform at least reasonably well. Last year this company commissioned MIRA to conduct a preliminary design study for an improved urban delivery vehicle. One of the findings was that the current TL 1631) tractor/trailer combination was "excellent in many ways".

Two of its strongest points are its good manoeuvrability and plenty of tolerance for unevenly distributed loads. The principal shortcomings are too high a load platform height at 1,054mm; relatively: poor access to the cab (although the Bedford is hardly worse in this respect than any other marque); and poor ride quality.

Bass also uses sonic rigid TLs. A disadvantage of these when used as a modern brewer's local delivery truck are their large turning circle — 14.6m.

Bass is looking for a vehicle with a turning circle of 10.6m and a platform height of only 760mrn. A step-frame, either on a rigid vehicle or on a semitrailer, can take platform height as low as that, but the step is always going to be a nuisance.

Then there is the question of ride. Bass, like other BTAC member companies, is keen to improve on current standards and as you would expect, fuel economy is an important consideration, too. The annual filel tally for all Bass vehicles, local delivery and trunkers, is around three million gallons.

When each of these requirements is investigated in more detail and then they are all brought together one is unavoidably led to a design of 16-tonne rigid which has front-wheel drive and air suspension.

Five years ago no manufacturer would even have considered such an odd-ball vehicle. Today, the brewer's proposals are being taken rather more seriously.

All kinds of elegant complex drive systems, including hydrostatic drive, have been suggested for the brewer's local delivery vehicles of the future. And at last month's Frankfurt Show, Kossbiihrer demonstrated that a relatively simple front-wheel-drive system for a vehicle of this size is a practical proposition.

KiissbohreriTitan vehicle uses MAN components including the cab, engine and drive/steer axle. A midmounted transfer box takes the drive forward from the conventionally sited gearbox to the front axle. The dead rear axle has air suspension and its tyres are low profile on I 5i ii diameter rims. The platform height of the vehicle at Frankfiirt was only 785mm (31in). You can he sure the UK's brewers will have taken note of this development.

• by Tim Blakemore