PROFIT FROM ADVERSITY

Page 60

Page 61

If you've noticed an error in this article please click here to report it so we can fix it.

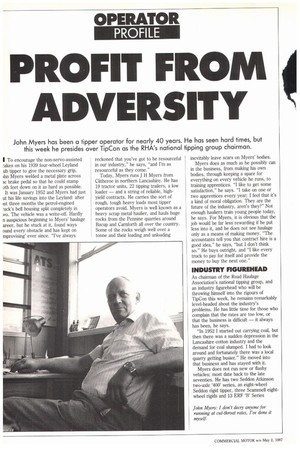

John Myers has been a tipper operator for nearly 40 years. He has seen hard times, but this week he presides over TipCon as the RHA's national tipping group chairman.

To encourage the non-servo-assisted rakes on his 1939 four-wheel Leyland ub tipper to give the necessary grip, )tin Myers welded a metal plate across le brake pedal so that he could stamp oth feet down on it as hard as possible. It was January 1952 and Myers had just ut his life savings into the Leyland: after ist three months the petrol-engined -uck's bell housing split completely in No. The vehicle was a write-off. Hardly n auspicious beginning to Myers' haulage areer, but he stuck at it, found ways ound every obstacle and has kept on mprovising' ever since. "I've always reckoned that you've got to be resourceful in our industry," he says, "and I'm as resourceful as they come."

Today, Myers runs J H Myers from Clitheroe in northern Lancashire. He has 19 tractor units, 22 tipping trailers, a low loader — and a string of reliable, highyield contracts. He carries the sort of rough, tough heavy loads most tipper operators avoid. Myers is well known as a heavy scrap metal haulier, and hauls huge rocks from the Pennine quarries around Bacup and Carnforth all over the country. Some of the rocks weigh well over a tonne and their loading and unloading inevitably leave scars on Myers' bodies.

Myers does as much as he possibly can in the business, from making his own bodies, through keeping a spare for everything on every vehicle he runs, to training apprentices. "I like to get some satisfaction," he says. "I take on one or two apprentices every year; I feel that it's a kind of moral obligation. They are the future of the industry, aren's they?" Not enough hauliers train young people today, he says. For Myers, it is obvious that the job would be far less rewarding if he put less into it, and he does not see haulage only as a means of making money. "The accountants tell you that contract hire is a good idea," he says, "but I don't think so." He buys outright, and "I like every truck to pay for itself and provide the money to buy the next one."

INDUSTRY FIGUREHEAD

As chairman of the Road Haulage Association's national tipping group, and an industry figurehead who will be throwing himself into the rigours of TipCon this week, he remains remarkably level-headed about the industry's problems. He has little time for those who complain that the rates are too low, or that the business is difficult — it always has been, he says.

"In 1952 I started out carrying coal, but then there was a sudden depression in the Lancashire cotton industry and the demand for coal slumped. I had to look around and fortunately there was a local quarry getting busier." He moved into that business and has stayed with it.

Myers does not run new or flashy vehicles; most date back to the late seventies. He has two Seddon Atkinson two-axle '400' series, an eight-wheel Seddon rigid tipper, three Scanunell eightwheel rigids and 13 ERF `B' Series tractors, all rated at 32.5 tonnes. He is going up to a 38-tonner for the first time soon, but remains dubious about the benefits of 38 tonnes in the market he operates in. When drivelines go Myers standardises on Gardners and Fuller 9509 crash boxes. "I'm a great believer in buying British," he says, and he mourns the passing of Scanunell: "I liked Scammels, they had a very robust chassis and a very good ground clearance."

Living and working in such conditions, tyres are a problem. "I insist that we check tyres every night when we're working on a hard job," he says. Myers uses mainly remoulds, bought from a local Michelin-recommended remoulder, Rossendale Vulcanising. Everyting is well worn, but well cared for — and in the tipping industry strength and staying power are more important than having the latest stereo in the cab.

TOUGHER TREATMENT

Myers is caught in the same dilemma as the rest of the tipping industry. He would like to see better enforcement, with tougher treatment for the cowboys — the industry could possibly adopt some form of self-regulatory system, he says — but at the same time he feels that it already suffers from undue harassment. "The police just don't seem to understand that where we need a motorway building, the materials — such as stone — are going to be hazardous loads to carry. The trucks are bound to get knocked about. I think an official police warning would do more good. They should bring the truck to the side of the road and get a book out and come back to the same job the following day, and if the haulier still has not cured the fault — then fair enough."

Myers remains highly sceptical that dynamic weighbridges are as accurate as they should be, especially if their results are to be given as evidence in cases taken out against hauliers: "Whenever you rerun a truck over a dynamic weighbridge, the readings vary. In fact, you hardly ever get the same reading twice."

At TipCon Myers is looking out for new ideas: "We've been discharging bulk loads by tipping up one end of the body since the year dot. It's about time someone found a new system." Costs have always curbed the best ideas in the past. "I'll be looking for some new aids to improve stability while tipping, too." He thinks that there are still far too many tipper collapses.

He wants to see the semi-automatic transmission systems on the market improved: "When they're good enough they've got to be good for business. They're bound to give you better fuel economy figures, especially over the Pennines."

More taper-frame tipping trailers would not go amiss either, thinks Myers: "They keep the centre of gravity low and it is important to keep the back of the trailer as close to the back wheels as possible." For 38-tonne tipping trailers, Myers reckons that a three-plus-two wheel configuration also helps keep stability at a premium. "Another thing," he says. "The driving test is wrong. It's not realistic, because you can take your HGV test in a lightweight tractor with an unladen singleaxle trailer using a syncromesh gearbox. I've had men come here after getting through the test who've given up after a couple of hours because they could not use a crash box. There is a world of difference between five tonnes and 32 tonnes."

Myers is very thorough in his approach to business. For instance, the bodies he designs and makes at his Clitheroe workshops carry at least a tonne weight penalty through having thicker corner pillars, vertical re-inforcing columns much closer together than normal, 12mm-thick specially-rolled floors and 6mm-thick double-skinned aluminium sidewalls.

"I'm very conservative. I've seen firms collapse over the years because a customer has gone into liquidation." Grow slowly — and grow carefully, he says. "This is a tough business. I don't decry anyone for running at cut-throat rates — I've done it myself in the past — but you shouldn't over-stretch yourself." Do your homework too: "I've worked it out that for every hour one of my trucks spends on the road, it gets 20 minutes maintenance."

0 by Geoff Hadwick