Ford Transcontinental.

Page 58

Page 59

If you've noticed an error in this article please click here to report it so we can fix it.

Its individual strengths.

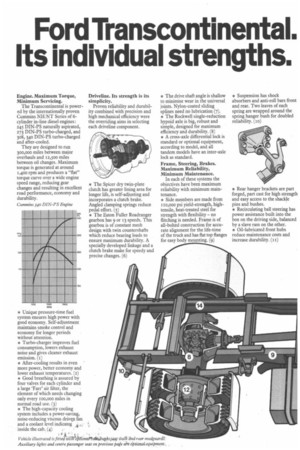

Engine. Maximum Torque, Minimum Servicing.

The Transcontinental is powered by the internationally proven Cummins NH/NT Series of 6cylinder in-line diesel engines: 245 DIN-PS naturally aspirated, 273 DIN-PS turbo-charged, and 308, 340 DIN-PS turbo-charged and after-cooled.

They are designed to run 300,000 miles between major overhauls and 12,500 miles between oil changes. Maximum torque is generated at around 1,400 rpm and produces a "flat" torque curve over a wide engine speed range, reducing gear changes and resulting in excellent road performance, economy and durability.

Cummins 340 DIN-PS Engine * Unique pressure-time fuel system ensures high power with good economy. Self-adjustment maintains smoke control and economy for longer periods • without attention.

* Turbo-charger improves fuel consumption, lowers exhaust noise and gives cleaner exhaust emission. (I) * After-cooling results in even more power, better economy and lower exhaust temperatures. (2) * Good breathing is assured by four valves for each cylinder and a large 'Farr' air filter, the element of which needs changing only every I00,000 miles in normal road use. (3) * The high-capacity cooling system includes a power-saving, noise-reducing viscous driven fan and a coolant level indicat% inside the cab. (4) Proven reliability and durability combined with precision and high mechanical efficiency were the overriding aims in selecting each driveline component.

* The Spicer dry twin-plate clutch has greater lining area for longer life, is self-adjusting and incorporates a clutch brake. Angled clamping springs reduce pedal effort. (5) * The Eaton Fuller Roadranger gearbox has 9 or 13 speeds. This gearbox is of constant mesh design with twin countershafts which reduce bearing loads to ensure maximum durability. A specially developed linkage and a clutch brake make for speedy and precise changes. (6) * The drive shaft angle is shallow to minimise wear in the universal joints. Nylon-coated sliding splines need no lubrication (7). * The Rockwell single-reduction hypoid axle is big, robust and simple, designed for maximum efficiency and durability. (8) * A cross-axle differential lock is standard or optional equipment, according to model, and all tandem models have an inter-axle lock as standard.

Frame, Steering, Brakes. Maximum Reliability, Minimum Maintenance.

In each of these systems the objectives have been maximum reliability with minimum maintenance.

* Side members are made from 110,000 psi yield-strength, hightensile, heat-treated steel for strength with flexibility — no flitching is needed. Frame is of all-bolted construction for accurate alignment for the life-time of the truck and has flat top flanges for easy body mounting. (9) * Suspension has shock absorbers and anti-roll bars front and rear. Two leaves of each spring are wrapped around the spring hanger bush for doubled reliability. (to) * Rear hanger brackets are part forged, part cast for high strength and easy access to the shackle pins and bushes.

* Recirculating ball steering has power assistance built into the box on the driving side, balanced by a slave ram on the other.

* Oil-lubricated front hubs reduce maintenance costs and increase durability. (ii) * Easy service access is achieved through hinged panels at the front of the cab or through tilting the cab itself.

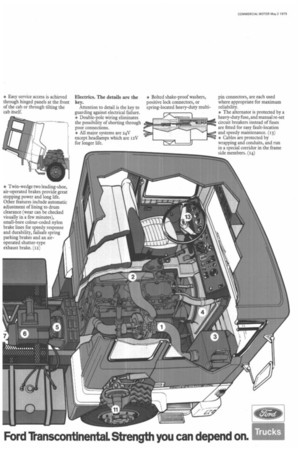

* Twin-wedge two leading-shoe, air-operated brakes provide great stopping power and long life. Other features include automatic adjustment of lining to drum clearance (wear can be checked visually in a few minutes), small-bore colour-coded nylon brake lines for speedy response and durability, failsafe spring parking brakes and an airoperated shutter-type exhaust brake. (12) Electrics. The details are the key.

Attention to detail is the key to guarding against electrical failure.

* Double-pole wiring eliminates the possibility of shorting through poor connections.

* All major systems are 24V except headlamps which are for longer life. pin connectors, are each used where appropriate for maximum reliability.

* The alternator is protected by a heavy-duty fuse, and manual re-set circuit breakers instead of fuses are fitted for easy fault-location and speedy maintenance. (r3) * Cables are protected by wrapping and conduits, and run in a special corridor in the frame side members. (I4)