ROADTEST HINO 6x4 TIPPER

Page 58

Page 59

If you've noticed an error in this article please click here to report it so we can fix it.

catch the eye. With the lightweight tipping gear fitted the 6x4's payload is 15,060kg, within a body/payload allowance of 16,430kg. We have taken the Renault G260 6x4, the Leyland Daf Constructor 24.23, and the Iveco Ford Cargo 2424C as comparisons, and their payload figures are: Renault, 15,760kg; Leyland Daf, 16,230kg; Iveco Ford, 14,640kg.

On the face of it then, the Hino has a fairly reasonable payload compared with the others, but this hides the fact that the Hino is fitted with a very lightweight body and tipping gear, and alloy wheels. A look at the body/payload allowances of the four trucks shows that the Hino is quite a heavy beast underneath all that aluminium. The figures are: Renault, 17,248kg; Leyland Daf, 17,822kg; Iveco Ford, 17,380kg.

On the positive side, the Hino does have some features that we liked. The electrical cab tilt is backed up with a manual system, so looking at the engine is a simple task with no worries in case the system goes wrong. The standard Hino tool kit is a splendid array of spanners, jack, bars — even a hammer. We thought the underslung near brake actuators might cause problems in off-road use, but the Hino had no problems, and the actuators remained clean and untouched.

• DRIVELINE

The engine in the 6x4, like its 8x4 stablemate, is a six-cylinder naturallyaspirated DI diesel. It replaced the MANdesigned turbocharged in-line six that was fitted to Hino trucks until about 1977. The MAN-designed unit had a reputation for unreliability, and a massive thirst. It failed to convince Hino's engineers of the benefits of turbocharging, and in the 8x4 the unit is a little breathless, and a turbocharger is being considered. In the 6x4, however, its power output of 181kW (243hp) stands up well against our comparison vehicles.

The gearbox is a Hino-designed sixspeed unit with synchromesh on the top four gears; first and second are very low ratios for site work. The rear axles are also Hino designs with steel-sprung singlereduction hypoid-type differentials, fitted with an axle lock that works across the axles, and not between them.

• PERFORMANCE

As might be expected the engine is very flexible, and fifth and sixth gears are the most frequent habitat for the gear lever. The Hino will pull up a gentle incline in top from as low as 1,000rpm, although we felt that extending the green period on the rev counter down to 900rpm was a little optimistic.

There seems to be plenty of power at the top end of the rev range too: one driver has assured us that he always drives his 6x4 Hino "in the red". If motorway journeys are attempted this would be the only way of keeping the tipper at the 96km/h (60mph) limit. If, however, one observes the niceties of engine rev limits, then the Hino's maximum speed is well short of that, and one is continually looking for a seventh gear.

The 6x4 is also available with a ninespeed constant-mesh Fuller gearbox, but the standard six-speed box is not as bad as it sounds.

In the top gears the lever loadings are minimal, and apart from the limited top speed we had no quibbles during the two-day test.

At the bottom of the gearbox the unsynchronised first and second gears are easy to select, as long as one makes the change with the engine revs in the green sector of the rev counter (between 900 and 1,700rpm).

In practice one would only want to select these gears up a particularly steep incline. When second gear is needed in a hurry a driver knows what has to be done in advance, and although doubledeclutching takes valuable time, there is none of the beligerent baulking as with an all-synchromesh gearbox.

On paper there is a long gap between fourth and fifth gears (witness our speed in gears chart) but we found little evidence of this on the road: the big engine just lugged up to peak torque again without any fuss.

• FUEL CONSUMPTION

Well-endowed with power the Hino's naturally-aspirated engine certainly is, but it doesn't shine in the economy stakes.

Part of the problem stems from the motorway section of our tipper route when the engine spent its entire time at peak revs, with the truck holding about 91km/h (56.5mph), The overall fuel consumption figures never fully recovered from this section, although we feel that the 34.2 lit/100km (8,26mpg) we obtained is a fair-reflection of the Hino's economy in typical service. This does not, however, compare well with our test sample, especially the Renault G260 that has more power than the Hino, but managed to give 28.81k/100km (9.8mpg). The Leyland Dal's 167kW gave a consumption of 31.48lit/100km (9mpg), and the Iveco Ford's 179kW gave 30.9 lit/100Im (9.1mpg).

• HANDLING

Theory has it that semi-elliptic leaf springs absorb the shock of road bumps and potholes. The action of the leaves sliding over one another provides sufficient friction to give some damping as well, but this form of damping suffers from the same problems as the friction damper: the initial rate of friction is much greater than when the leaves are moving against one another.

This phenomenon, colloquially known as "stiction", explains why the Hino's undamped rear bogie is so bumpy. The steel-sprung rear bogie also suffers from a slight lack of articulation, compared with systems like the Hendrickson system which is featured on the Renault G260 (CM 1-7 December 1988).

Hard cornering on tarmac can result in rear wheel lift even when laden, and if road bumps are sufficiently high when the front wheels of the bogie are on the bump, the rear wheels dangle in the air. While the brakes give reasonable stopping distances they seemed to have a delayed reaction and we were glad of the steeringcolumn-mounted exhaust brake control which can be set to come on when the driver's foot comes off the accelerator, if the clutch is fully engaged.

Hino says that this should be left on all the time, as the exhaust braking is fairly good. Leaving the system working means the truck will not roll along roads on a trailing throttle and fuel is wasted, so we switched it off.

• CAB COMFORT

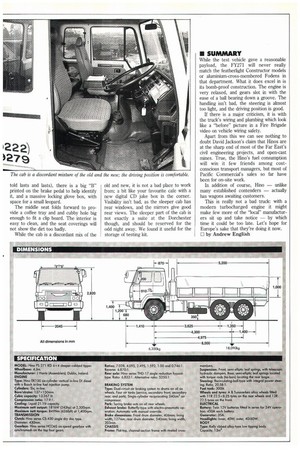

On climbing into the Hino one is struck by the door handles and locks. Chromiumplated and streamlined, they look straight out of a 1950s BMC parts catalogue. The instruments are modern in contrast, but the layout is somewhat inexplicable. Eyelevel ventilators work well, and the heater seemed competent on the frosty mornings of the test.

The steering wheel adjusts for height and rake which, with the mechanicallysprung seat, provides a very comfortable driving position. We found the steering power assistance a little too much on fast motorways, but it did make light work of off-road operation.

The Hino is blessed with the first tipping controls we have encountered that don't look like the on-switch to Frankenstein's monster. They fit in with the interior trim, and are easy to use. And what an interior trim it is. As well as that tasteful leopard-skin lino (which we are told lasts and lasts), there is a big "B" printed on the brake pedal to help identify it, and a massive locking glove box, with space for a small leopard.

The middle seat folds forward to provide a coffee tray and and cubby hole big enough to fit a clip board. The interior is easy to clean, and the seat coverings will not show the dirt too badly.

While the cab is a discordant mix of the old and new, it is not a bad place to work from; a bit like your favourite cafe with a new digital CD juke box in the corner. Visibility isn't bad, as the sleeper cab has rear windows, and the mirrors give good rear views. The sleeper part of the cab is not exactly a suite at the Dorchester though, and should be reserved for the odd night away. We found it useful for the storage of testing kit.

While the test vehicle gave a reasonable payload, the FY271 will never really match the featherlight Constructor models or aluminium-cross-membered Fodens in that department. What it does excel in is its bomb-proof construction. The engine is very relaxed, and gears slot in with the ease of a ball bearing down a groove. The handling isn't bad, the steering is almost too light, and the driving position is good.

If there is a major criticism, it is with the truck's wiring and plumbing which look like a "before" picture in a Fire Brigade video on vehicle wiring safety.

Apart from this we can see nothing to doubt David Jackson's claim that Hinos are at the sharp end of most of the Far East's civil engineering projects, and open-cast mines. True, the Hino's fuel consumption will win it few friends among costconscious transport managers, but most of Pacific Commercial's sales so far have been for on-site work.

In addition of course, Hino — unlike many established contenders — actually has wagons awaiting customers.

This is really not a bad truck: with a modern turbocharged engine it might make few more of the "local" manufacturers sit up and take notice — by which time it could be too late. Let's hope for Europe's sake that they're doing it now. 0 by Andrew English