Wi

Page 88

Page 89

Page 90

Page 95

Page 96

If you've noticed an error in this article please click here to report it so we can fix it.

krs

Fro

8.11

A

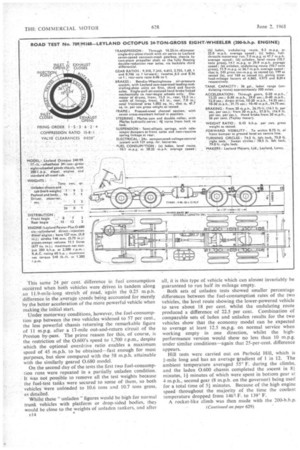

Latest Leyland Octopus Models Availabk performance 200-b.h.p. Diesel Engines Corn, 'ice of "Economy" 140-b.h.p. or High's Show Differing Advantages of Each Type

IT is unlikely that such sweeping changes to a complete range of heavy-goods vehicles have ever been made in one move as those carried out last year by Leyland Motors, Ltd. Their new Beaver, Hippo and Octopus designs resemble the previous models virtually in respect of the wheels and tyres only, and there is no doubt in my mind that this latest range will quickly prove to be the most popular Leylands ever introduced in this country.

Part of the success lies in the remarkable development work carried out on the old engines which were used in the previous models. Years of research into combustion characteristics have resulted in two outstanding diesel engines: one.an :` economy " unit with a net rating of 140 b.h.p. at 1,700 r.p.m. (b.m.e.p., 115 psi.), and the other a high-performance unit giving 200 b.h.p. (net) at 2,200 r.p.m. (h.m.e.p., 120 p.s.i.). Both these engines have been type named Power-Plus, and recently I was able to make direct comparative tests between two Octopus chassis equipped with these engines.

The results obtained are detailed in the separate data panels reproduced on the following pages, and comparison between the two sets of figures reveals that each of the two engines does all that the makers claim, the " economy " unit achieving 12.55 m.p.g. at 28 m.p.h. average speed along a level road and 11 m.p.g. at 34.8 m.p.h. average speed under full-throttle motorway conditions, whilst the 200-b.h.p. engine gave 10.1 m.p.g. on a level road, and 7 m.p.g. at 47.7 m.p.h. on a motorway, with acceleration from a standstill to 30 m.p.h. in 29 seconds.

I know of no other eight-wheelers that can match consistently the economy of the one chassis or the high-speed performance of the other, and Leyland are to be admired for being able to offer two such basically similar vehicles with widely differing performances to suit the two schools of thought in the British haulage business—maximum fuel economy with average Performance or average fuel economy with maximum performance.

The new Leyland models were comprehensively described and illustrated, at the time of their introduction, in The Commercial Motor dated September 9, 1960. This article revealed . most of the innovations of this new range, such as the new engines; an entirely new five-speed F I 2

gearbox to which could be added either or both of two additional ratios; a completely new braking system which included an air-assisted hand-brake layout; new doublereduction rear axles, with manually operated third-differential lock on double-drive bogies; non-reactive four-spring rear suspension for maximum wheel adhesion, with the option of a high-articulation two-spring system; powerassisted steering as standard; and the adoption of all-steel or plastics-panelled cabs with easy-access steps ahead of the front wheels.

Such completely new and comprehensive specifications have never been offered on what may be called massproduced heavy vehicles before, and only a concern with the high production capacity of Leyland Motors could possibly do this for a price within £400 of that of the nearest equivalent previous models, the performances of which look quite shabby compared with those of these newest entrants. Not only are the prices of the new vehicles highly competitive with those of their predecessors but, even more important, they are equally competitive with anything else approaching the same standard available in Great Britain. In short, Leyland's new maximum-capacity Power-Pius models offer value for money par excellence, and by permutating a relatively small number of standard components the manufacturers are able to offer four-, sixand eight-wheelers with performances to suit all tastes, operating conditions and, in a sense, pockets.

Both the vehicles made available to me for these comparative tests were Octopus 240.9R 17-ft.-wheelbase models. The high-performance chassis had the Power-Plus 0.680 200-b.h.p. diesel engine, basic five-speed ?earbox with I, both optional additional ratios, double-drive rear bogies, and standard all-steel cab, in which condition its kerb weight was 7 tons 9+ cwt.

The other chassis had the Power-Plus 0.600 140-b.h.p. unit, five-speed gearbox with optional sixth overdrive ratio, single-drive rear bogie and optional plastics-panelled cab. Short of omitting the sixth ratio (37 lb.), this is the lightest version of the standard Octopus available, and the kerb weight of the chassis-cab tested was only 6 tons 14+ cwt. As tested, however, a Homalloy platform body was mounted, but for the sake • of effecting the most useful comparisons the weight of this body has been added to the payload in the data panel, the weight of the test load imposed upon the body being in the region of 16+ tons.

As it turned out, the " economy " Octopus was grossing nearly I ton more than the other vehicle with two people and test equipment in the cab, but this relatively small difference would have had a negligible effect on the comparative performances. Another slight difference was that the lighter vehicle was shod with Michelin " X " tyres, and no spare wheel or carrier were fitted. The standard spare-wheel carrier, incidentally, is of the winch type. , For the first performance tests both vehicles were taken out to a quiet level stretch of road to obtain retardation figures. As the lighter vehicle had been supplied purely for engine-performance comparisons, its brakes had not been correctly set-up recently, so the figures recorded in both panels were obtained with the newer vehicle. Checks made with the chassis with the 0.600 engine showed that, despite its lack of attention, the braking performances were only slightly inferior to those of the prepared vehicle.

The recorded stopping distances are particularly good for a 24-ton-gross machine with brakes on six

wheels only, the retardation from 30 m.p.h.

being a 30-per-cent. improvement on the distances recorded in 1956 with the then current Octopus running at the same gross weight.

Striking also is the hand-brake performance. which shows the relatively inexpensive provi sion of an air servo in the system to provide a really useful emergency brake which places hardly any reliance upon the driver's strength for its effectiveness.

Following these tests, fuel-consumption figures were taken over a 10-mile narrow, undulating route, on the hills of which the more powerful vehicle had a speed advantage, which accounts for the differences in the recorded average speeds. The route chosen would give results very close to those that could be expected with each vehicle on a normal nonmotorway trunking run between city centres, and the tests showed that, by restricting the maximum speed of both vehicles to approximately 33 m.p.h., the " economy " model can be 24 per cent. more economical without anything like the same relative difference in journey times. This same 24 per cent. difference in fuel consumption occurred when both vehicles were driven in tandem along an 11.9-mile-long stretch of road, again the 0.25 m.p.h. difference in the average speeds being accounted for merely by the better acceleration of the More powerful vehicle when making the initial start. Under motorway conditions, however, the fuel-consumption gap between the two vehicles widened to 57 per cent., the less powerful chassis returning the remarkable figure of 11 m.p.g. after a 17-mile out-and-return circuit of the Preston by-pass. The prime reason for this, of course, is the restriction of the 0.600's speed to 1,700 r.p.m., despite which the optional overdrive ratio enables a maximum speed of 45 m.p.h. to be obtained-fast enough for most purposes, but slow compared with the 58 m.p.h. attainable with the similarly geared 0.680 model. On the second day of the tests the first two fuel-consumption runs were repeated in a partially unladen condition. It was not possible to remove all the test weights because the fuel-test tanks were secured to some of them, so both vehicles were unloaded to 10.6 tons and 10.7 tons gross, as detailed.

Whilst these " unladen " figures would be high for normal trunk vehicles with platform or drop-sided bodies, they would be close to the weights of unladen tankers, and after all, it is this type of vehicle which can almost invariably be guaranteed to run half its mileage empty.

Both sets of unladen tests showed smaller percentage differences between the fuel-consumption rates of the two vehicles, the level route showing the lower-powered vehicle to save about 18 per cent. whilst the undulating route produced a difference of 22.5 per cent. Combination of comparable sets of laden and unladen results for the two vehicles show that the economy model can be expected to average at least 12.5 m.p.g. on normal service when working empty in one direction, whilst the highperformance version would show no less than 10 m.p.g. under similar conditions-again that 25-per-cent. difference appears.

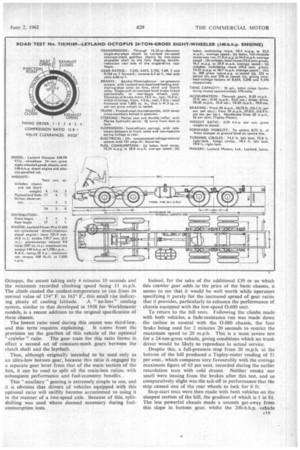

Hill tests were carried out on Parbold Hill, which is 1-mile long and has an average gradient of 1 in 12. The ambient temperature averaged 55° F. during the climbs, and the laden 0.600 chassis completed the ascent in 81 minutes, 11 minutes of which were spent in bottom gear at 4 m.p.h., second gear (8 m.p.h. on the governor) being used for a total time of 51 minutes. Because of the high engine speed throughout the majority of the time the coolant temperature dropped from 140 F. to 139' F.

A rocket-like climb was then made with the 200-h.h.p. Octopus, the ascent taking only 4 minutes 10 seconds and the minimum recorded climbing speed being 11 m.p.h. The climb caused the coolant-temperature to rise from its normal value of 154° F. to 163° F., this small rise indicat ing plenty of cooling latitude. A "no-loss" cooling system, similar to that developed in 1958 for Worldmaster models, is a recent addition to the original specification of these chassis.

The lowest ratio used during this ascent was third-Iowa

and this term requires explaining. It sJerns from the provision on the gearbox of this vehicle of the optional " crawler" ratio. The gear train for this ratio forms in effect a second set of constant-mesh gears between the clutch shaft and the layshaft.

Thus, although originally intended to be used only as an ultra-low bottom gear, because this ratio is engaged by a separate gear lever from that of the main section of the box, it can be used to split all the main-box ratios, with subsequent performance and fuel-economy benefits.

This 'auxiliary" gearing is extremely simple to use, and it is obvious that drivers of vehicles equipped with this optional ratio will swiftly become accustomed to using it in the manner of a two-speed axle. Because of this, splitshifting was used where deemed necessary during fuelconsumption tests. Indeed, for the sake of the additional £30 or so which this crawler gear adds to the price of the basic chassis, it seems to me that it would be well worth while operators specifying it purely for the increased spread of gear ratios that it provides, particularly to enhance the performance of chassis equipped with the low-speed 0.600 unit.

To return to the hill tests. Following the climbs made with both vehicles, a fade-resistance run was made down the incline in neutral with the 0.680 chassis, the foot brake being used for 2 minutes 20 seconds to restrict the maximum speed to 20 m.p.h. This is a most severe test for a 24-ton-gross vehicle, giving conditions which no trunk driver would be likely to reproduce in actual service.

Despite this, a full-pressure stop from 20 m.p.h. at the bottom of the hill produced a Tapley-meter reading of 51 per cent., which compares very favourably with the average maximum figure of 65 per cent. recorded during the earlier retardation tests with cold drums. Neither smoke nor smell were issuing from the brakes after this test, and so comparatively slight was the tail-off in performance that the stop caused one of the rear wheels to lock for 6 ft. • Stop-start tests were then made with both vehicles on the steepest section of the hill, the gradient of which is 1 in 64. The less powerful chassis made a smooth get-away from this slope in bottom gear. whilst the 200-b.h.p. vehicle needed only second gear (with the " auxiliary " gearing giving direct drive). The hand brakes of both vehicles held them easily On this gradient, and neither during these tests nor the preceding non-stop climbs were any signs of smoking seen at the exhaust outlets.

In fact, smoke-free performance was a commendable feature of both test vehicles, and Leyland have become smoke conscious to the extent of subjecting all their production engines to smoke tests, a maximum figure of 25 per cent. on the Hartridge meter being the top limit—the degree of smoke permitted under such circumstances being virtually invisible to the human eye in any case.

Acceleration tests revealed outstanding performance in the case of the 0.680 chassis, split shifting not being employed when making the standing-start tests. As might be expected, the acceleration performance of the lower powered vehicle was not so startling, but, nevertheless, many operators of eight-wheelers are quite accustomed to this type of performance—and worse—and consider the fueleconomy benefits to be of greater importance.

While the 200-b.h.p. vehicle was unladen, full-pressure footand hand-brake stops were made from 20 m.p.h. to assess the effectiveness of the non-reactive rear-bogie spring la;out, previous experience with this system having shown it to be of most advantage when unladen rather than laden. Retardations of up to 77 per cent. were recorded with the foot brake and 52 per cent. with the hand brake, and in all cases all the rear wheels locked evenly at first; followed by alternating axle hop for the last few feet before coming to rest. When braking fully laden no axle -hop was observed.

Both vehicles handled extremely well at all times, and because the latest 0.600 unit runs more quietly than its immediate predecessor, the lower powered vehicle was particularly fatigue-free to drive, even though more gear changing was necessary than with the other chassis: The noise level of the 0.680 unit is somewhat high, particularly in an all-steel cab, but tests are in hand at the moment to decide upon a suitable cowl-insulating material.

The new Leyland gearbox is decidedly more pleasant to use than the unit it replaces, and the gear lever is located conveniently close to the steering wheel. Although air assistance is applied to the hydraulic operating mechanism of the clutch on the 0.680 engine, its action tended to be slightly heavier than that of the unas,_:ted clutch of the smaller unit.

Steering was above reproach, being positive without any trace of wander, whilst retaining good castor action. Even when unladen it never becomes too light, and there is a E20 relief valve in the hydraulic circuit to prevent the wheels being turned while the vehicle is stationary.

The cab is well laid out, although additional grab handles to the rear of the door openings would assist access to either seat even more, and facia-panel fittings include an engineoil-level gauge and a lockable glove compartment.

Because telescopic dampers are standard at both front axles the cab ride is generally good at all times, and when cornered quickly neither Octopus displayed any vicious roll tendencies. A chassis detail which I must criticize and which I hope will be put right soon is that the fuel-tank filler neck is too short and badly positioned so that when a normal body is fitted, as in the case of the 0.600 test vehicle, the filler orifice is almost inaccessible.

Brief maintenance tests indicated good overall accessibility. The water level took me 20 seconds to check, but this job would have been quicker had the tiller cap been easier to reach and to turn. Using the gauge the engine-oil level was checked in 3 seconds, hut a dip-stickocheck took me 65 seconds because the cowl has to be raised and the nearside panel removed.

The same spanner fits the gearbox and driving-axle level plugs, a gearbox-level check taking me 35 seconds whilst each of the rear axles was checked in 28 seconds. The batteries are securely housed but readily accessible, a level check taking I minute 50 seconds, whilst the level of the oil in the reservoir for the steering-servo system was verified in 10 seconds.

The clutch hydraulic master cylinder has an integral reservoir, access to which is given by a trap in the driver's floor plate. This level took 11 minutes to check.

I did not work on the fuel system, but noted that the primary filter, which is attached to the side member immediately ahead of the fuel tank, is positioned a little too high, so that it would be awkward to work on once the body had been mounted. An injector change would he the same as on the previous Leyland units.

Bendix-Westinghouse slack adjusters are fitted at all the brakes so that, by not jacking up the wheels, I was able to adjust each rear brake in 30 seconds and each front brake in 40 seconds.

At home, the 240.9R I7-ft.-wheelbase chassis with 0.600 eogine, non-reactive suspension, double-drive bogie and steel cab costs in the region of £4,200. The alternative 0.680 engine adds about £50 to this price, whilst the specification of a single-drive bogie reduces the price by £150. Each of the two additional gearbox ratios cost about £30, whilst the plastics-panelled cab adds approximately £120 to the price of the chassis with steel cab.