The maintenance of Ball and Roller Bearings

Page 72

If you've noticed an error in this article please click here to report it so we can fix it.

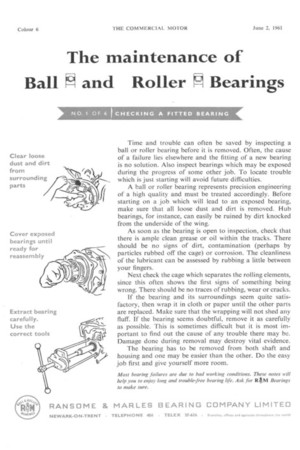

NO 1 OF 6 CHECK A FITTED B iNG Time and trouble can often be saved by inspecting a ball or roller bearing before it is removed. Often, the cause of a failure lies elsewhere and the fitting of a new bearing is no solution. Also inspect bearings which may be exposed during the progress of some other job. To locate trouble which is just starting will avoid future difficulties.

A ball or roller bearing represents precision engineering of a high quality and must be treated accordingly. Before starting on a job which will lead to an exposed bearing, make sure that all loose dust and dirt is removed. Hub bearings, for instance, can easily be ruined by dirt knocked from the underside of the wing.

As soon as the bearing is open to inspection, check that there is ample clean grease or oil within the tracks. There should be no signs of dirt, contamination (perhaps by particles rubbed off the cage) or corrosion. The cleanliness of the lubricant can be assessed by rubbing a little between your fingers.

Next check the cage which separates the rolling elements, since this often shows the first signs of something being wrong. There should be no traces of rubbing, wear or cracks.

If the bearing and its surroundings seem quite satisfactory, then wrap it in cloth or paper until the other parts are replaced. Make sure that the wrapping will not shed any fluff. If the bearing seems doubtful, remove it as carefully as possible. This is sometimes difficult but it is most important to find out the cause of any trouble there may be. Damage done during removal may destroy vital evidence.

The bearing has to be removed from both shaft and housing and one may be easier than the other. Do the easy job first and give yourself more room.

Most bearing Pilures are due to bad working conditions. These notes will help you to enjoy long and trouble-free bearing life. Ask for 114111 Bearings to make sure_