Closing the gap

Page 68

Page 69

If you've noticed an error in this article please click here to report it so we can fix it.

Vehicles and on-board computers

CAR SALESMEN know that offering a potential buyer too much choice is a mistake.

The same is true in other situations. If your company has had demonstrations of computer equipment, you must now have some sympathy for the computer people. Frequently, the original reason for the demonstration is lost in the stream of questions: "What if we could do this?" and "What if we add this?" It is a disaster.

While the after-market manufacturers seem convinced of the need for onboard systems, some vehicle manufacturers seem to be exercising restraint, and others are working enthusiastically to offer options for addition to their standard vehicles.

In general, the priorities of development in vehicle technology will respond to each manufacturer's view of its market segment.

The other on-board applications of microelectronics are principally as options using computers for fuel consumption or service requirements. Since these are mainly systems on offer in the car market, the emphasis is on driver information.

Several people believe that in the future we, as drivers, will be told what we need to know rather than see it on dashboard instruments.

The defenders of audio systems believe the need to inform the driver by voice will become more important in the future as other computer-based systems provide more information requiring the driver's visual attention. One such future system could be a vehicle navigation system, although Renault's M. Angello believes navigation systems may tell us where we should turn right or

search Laboratory (TRRL) at Crowthorne, has estimated that around £400m per year could be saved if we had a countrywide route guidance system (1982 prices).

Others have suggested higher figures: John Wootton of Wootton and Jefferies believes that up to seven per cent of the distance driven by each of us may be unnecessary; that in vehicle costs and driver's time the wastage could be approximately £2,000m at today's prices.

There are basically three methods of providing drivers with information about road conditions.

The cheapest system uses an extension of the Prestel type links to give the route advice before the driver starts his journey. The cost of using this sort of system is estimated to be approximately £3 for a commercial vehicle. The second alternative uses a self-contained vehicle-mounter unit which has an electronic map of the UK road network — naturally, the frequency with which this 'map' is updated dictates the timeliness of the route information.

Once set by the driver on the start of the journey the instructions are displayed as the journey progresses. Unlike the first method, this system needs no injection of public money; the system is bought by the owner of the vehicle. The cost of a unit is estimated to be in the region of £400.

The third method is more sophisticated and combines the principles of the other two. The vehicle is fitted with a unit which looks at electronic signposts on the roadside and plots its route and establishes the road conditions as it moves. The vehicle unit would be cheaper, at a cost of around £100. This is less than the other on-board device which needed to store its own map.

This third method has the advantage of always being fed with current information from the roadside. The system would require the government to spend approximately £250m on the roadside equipment with

Above: Route guidance systems based on electronic roadside equipment could not respond to the commercial objectives of individual hauliers or coach operators. This is because there are 10 cars on the road for every commercial vehicle.

the risk that drivers or operators might not buy the on-board units and so the savings would not be made.

At first sight the provision of a national network for route guidance would appear to be good for the freight industry and the more the cost is borne by government the better, although we all pay eventually.

The objectives of the freight or coach industry may, however, be somewhat different from the Government's or local authorities' aims for route guidance. Traffic manage ment is the key objective in local authorities and the Department of Transport and, as a result, road users (on average) benefit through shorter delays at traffic lights and safer journeys, and route guidance systems based on electronic roadside equipment can make it easier to control traffic.

Minor technical changes to the technology could extend the control provided for routeing purposes to various other traffic control problems, including law enforcement. There are approximately 10 cars for every van and truck. Consequently, such public systems could not respond to the commercial objectives of individual truck or coach operators.

However, a dedicated selfcontained vehicle system might be programmed so that the route was "best" when judged from the operator's commercial circumstances. Many vehicles run on regular routes and the question of "best" route does not arise.

Where a route choice does exist the best is usually selected from one of two options; either the route is quickest or it is cheapest. Whether the quickest is also the cheapest will depend upon a number of factors.

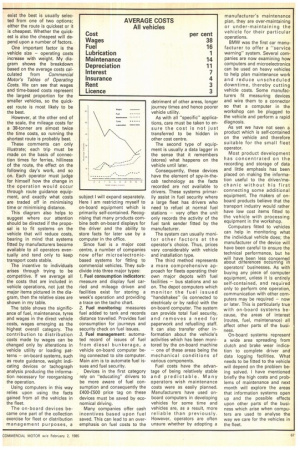

One important factor is the vehicle size — operating costs increase with weight. My diagram shows the breakdown based on the average costs calculated from Commercial Motor's Tables of Operating Costs. We can see that wages and time-based costs represent the largest proportion for the smaller vehicles, so the quickest route is most likely to be the best.

However, at the other end of the scale, the mileage costs for a 38-tonner are almost twice the time costs, so running the shortest route is probably best.

These comments can only illustrate; each trip must be made on the basis of connection times for ferries, hilliness of the route, the effect on the following day's work, and so on. Each operator must judge for himself how the change in the operation would occur through route guidance equipment, and exactly what costs are traded off in minimising time or minimising distance.

This diagram also helps to suggest where our attention should be directed if the proposal is to fit systems on the vehicle that will reduce costs, bearing in mind that systems fitted by manufacturers become available to all operators eventually and tend only to keep transport costs stable.

The incentive to individuals arises through trying to be competitive. If we average all the costs that are included in vehicle operations, not just the major items pictured in the diagram, then the relative sizes are shown in my table.

The table shows the significance of fuel, maintenance, tyres and wages in the direct vehicle costs, wages emerging as the highest overall category. The contribution to distribution costs made by wages can be changed only by alterations in vehicle utility or loading patterns — on-board systems, such as route guidance, weight indicating devices or tachograph analysis producing the information necessary for reorganising the operation.

Using computers in this way relies upon using the facts gained from all the vehicles in the fleet.

The on-board devices became one part of the collection exercise for fleet or distribution management purposes, a subject I will expand separately. Here I am restricting myself to on-board equipment which is primarily self-contained. Recognising that many pp)clucts combine both on-board displays for the driver and the ability to store facts for later use by a computer in the office.

Since fuel is a major cost centre, a number of companies now offer microelectronicbased systems for fitting to commercial vehicles. They subdivide into three major types: 1, Fuel consumption indicators: measure and display fuel carried and mileage driven and facilities exist for storing a week's operation and providing a trace on the tacho chart.

2, Fuel monitoring: measures fuel added to tank and records distance travelled. Provides fuel consumption for journeys and security check on fuel issues.

3, Fuel management: automated record of issues of fuel from diesel bunkerage, a vehicle on-board computer being connected to site computer. Main aim is to automate fuel issues and fuel security.

Devices in the first category rely on "educating" drivers to be more aware of fuel consumption and consequently the £400-£500 price tag on these devices must be saved by economical driving.

Many companies offer cash incentives based upon fuel saved. This can lead to an overemphasis on fuel costs to the detriment of other areas, longer journey times and hence poorer vehicle utility.

As with all "specific" applications, care must be taken to ensure the cost is not just transferred to be hidden in other cost centre.

The second type of equipment is usually a data lagger in the sense that it remembers (stores) what happens on the vehicle until later.

Consequently, these devices have the element of spy-in-thecab technology as the facts recorded are not available to drivers. These systems primarily assist in fuel security where a large fleet has drivers who need to refuel at normal fuel stations — very often the unit only records the activity of the fuel tank sender fitted by the manufacturer.

The system can usually monitor other factors at the operator's choice. Thus, prices vary considerably with vehicle and installation type.

The third method represents a more comprehensive approach for fleets operating their own major depots with fuel facilities — bus stations and so on. The depot computers which monitor the fuel issued "handshakes" (is connected to electricaly or by radio) with the on-board computer. The system can provide total fuel security, and removes a need for paperwork and refuelling staff. It can also transfer other information about the vehicle's activities which has been monitored by the on-board machine — one of these areas being the mechanical conditions of various components.

Fuel costs have the advantage of being relatively stable and predictable. Many operators wish maintenance costs were as easily planned. Manufacturers have used onboard computers in developing vehicles for some time and vehicles are, as a result, more reliable than previously. However, operators are often unsure whether by adopting a manufacturer's maintenance plan, they are over-maintaining or under-maintaining the vehicle for their particular operations.

BMW was the first car manufacturer to offer a "service warning" system. Several companies are now examining how computers and microelectronics can be used on heavy vehicles to help plan maintenance work and reduce unscheduled downtime, thereby cutting vehicle costs. Some manufacturers fit measuring devices and wire them to a connector so that a computer in the workshop can be plugged to the vehicle and perform a rapid diagnosis.

As yet we have not seen a product which is self-contained on the vehicle and therefore suitable for the small fleet operator.

Most product development has concentrated on the recording and storage of data and little emphasis has been placed on making the information useful to the driver/mechanic without his first connecting some additional equipment. The makers of onboard products believe that the transport industry would rather have low cost items fitted to the vehicle with processing equipment in the workshop.

Computers fitted to vehicles can help in monitoring what the individual vehicle does; the manufacturer of the device will have been careful to ensure the technical performance, but he will have been less concerned about differences occurring in operators' businesses. As with buying any piece of computer equipment, unless it is entirely self-contained, and required only to perform one operation, communication with other computers may be required — now or later. This is particularly true with on-board systems because, the areas of interest (routes, fuel, maintenance) all affect other parts of the business.

On-board systems represent a wide area spreading from clutch and brake wear indication to complete driver and data logging facilities. What needs to be fitted to the vehicle will depend on the problem being solved. I have mentioned briefly the high costs and problems of maintenance and next month will explore the areas that information systems open up and the possible effects upon other parts of the business which arise when computers are used to analyse the way we care for the vehicles in the fleet.