Ai. NEW. DUAL-PURPOSE

Page 54

Page 55

Page 56

If you've noticed an error in this article please click here to report it so we can fix it.

FOUR-TONNER

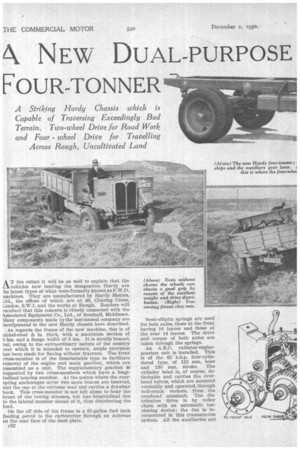

A T the outset it will be as well to explain that the L./vehicles now bearing the designation Hardy are he latest types of what were formerly known as F.W.D. nachines. They are manufactured by Hardy Motors, Ltd., the offices of which are at 46, Charing Cross, London, S.W.1, and the works at Slough. Readers will recollect that this concern is closely connected with the kssociated Equipment Co., Ltd. of Southall, Middlesex.

any components made by the last-named company are mcorporated in the new Hardy chassis here described.

As regards the frame of the new machine, this is of aickel-steel 156 in. thick, with a maximum section of 3 ins, and a flange width of 3 ins. It is stoutly braced, but, owing to the extraordinary nature of the country Dver which it is intended to operate, ample provision has been made for flexing without fracture. The front cross-member is of the demountable type to facilitate removal of the engine and main gearbox, which are assembled as a unit. The supplementary gearbox wt supported by two cross-members which have a longitudinal bracing member. At the points where the rearspring anchorages occur two more braces are inserted, and the one at the extreme rear end carries a drawbar hook. This cross-member is not left alone to hear the brunt of the towing stresses, but has longitudinal ties to the lateral member ahead of it, thus distributing the load.

On the off side of the frame is a 35-gallon fuel tank feeding petrol to the carburetter through an Autovac on the rear face of the dash plate.

c32 Semi-elliptic springs are used for both axles, those at the front having 16 leaves and those at the rear 14 leaves. The drive and torque of both axles are taken through the springs.

An A.E.C. radiator-enginegearbox unit is installed. This is of the 65 b.h.p. four-cylindered type, of 112 mm. bore and 130 mm. stroke. The cylinder tread is, of course, detachable and carries the overhead valves, which are mounted vertically and operated, through bell-crank rockers, from the overhead camshaft. The distribution drive is by roller chain with an automatic tensioning device; the fan is incorporated in this transmission

mounted on the near side of the engine to give more space on the off side for the driver and controls. A point of -difference from the standard A.E.C. specification is that the sump has been altered in order to give the necessary large clearance above the front axle, which Is of the live pattern.

A single-plate clutch, 16 ins. in diameter, is used ; this has a total wearing surface of 380 sq. ins., and an adjustable stop is provided.

The main gearbox provides four forward speeds and one reverse. The gearwheels are exceedingly wide and are carried on 21-in. shafts, both the gears and the shafts being ground. On the near side of the gearbox is situated a tyre pump of David manufacture.

From the main gearbox a short propeller shaft runs to an auxiliary box which affords two speeds, thus giving in all eight forward ratios and two in reverse. Optional direct-drive ratios are: 6/, 7/, 81, 91, and lOi to 1. Assuming a 7/ to 1 top gear to be provided, the complete series of overall ratios is as follows :—High. set, 7.25, 11.52, 19.5, 31.7 to 1, giving road speeds, at 2,000 r.p.m. of the engine, of 31.2 m.p.h., 19.6 m.p.h., 11.6 m.p.h., and 7.5 m.p.h. In reverse, which is 38.65 to 1, the speed is 5.9 m.p.h. As regards the law set, the ratios are : 13.5, 21.45, 36.3 and 59.1 to 1, giving road speeds of 16.8 m.p.h., 10.5 m.p.h., 6.25 m.p.h. and 3.8 m.p.h. The maximum tractive effort developed is 6,420 lb.

Much interest attaches to this auxiliary gearbox, a partly sectioned view of which we reproduce. The box contains three shafts, viz., the primary directly coupled to the engine; secondly, an intermediate shaft from which may be operated a power take-off ; and, thirdly, a driven shaft carrying power to the front axle when the low series of ratios is in operation. Movement of the auxiliary gear lever, bringing into action the low series, automatically moves backwards the pinion on the tertiary shaft bringing into engagement the secondary, thus causing the drive to be conveyed to both front and rear axles. When the high series is in operation the enginefirives only the rear axle.

This gearbox is three-point suspended and drives to both axles through shafts with Hardy Spicer joints. A speedometer drive is provided on the main shaft and there is a Simms magnetic oil filter. The casing contains two apertures above the secondary shaft into which can be fitted a power take-off, if required.

In addition to the selector-locking mechanism in the auxiliary gearbox, there is a further locking plunger on the lever to prevent its movement owing to extreme bouncing of the chassis on cross-country work.

Both axles are, in the main, of A.E.C. design, but, of course, the forward one incorporates the familiar p.w.D. system allowing the front wheels both to drive and steer.

The rear axle is of the semi-floating pattern, and the front axle is fully floating, but both have overhead worms, and rubber buffers are provided to prevent metal-to-metal contact between the casings and the frame when traversing very rough ground.

Directional control is by means of a Manes steering gear, the drop arm of which operates transversely. The standard tyre equipment consists of 38-in. by 7-in. pneumatics. A Clayton Dewandre vacuum servo amplifies the driver's effort on the brake pedal, and the force is then carried to a cross-shaft with spherical bearings. A master adjustment is provided at this

poinf, after which a relay shaft is used, and thence the couplings run to independent pairs of shoes in the rearwheel drums, one set being hand-opeiated.

Grouped lubrication is employed, two batteries of gun points being arranged on the chassis side-member.

The permissible load of the new Hardy is 4 tons, plus the body, and the leading dimensions are as follow :—Wheelbase, 12 ft. 1 in. ; track, 5 ft. 10 Ins. (front), 5 ft. 7 ins. •(rear) ; frame width, 3 ft. 6 ins.; body. length, 14 IL; loading height, 3 IL 9 ins. ; overall length, 18 ft. 4g ins., without the starting handle, For main-road work, when the high series of ratios Is in use, only the rear wheels drive. For cross-country• duty, when the low series of ratios functions, the Hardy drives through all four wheels. The striking advantages of driving the front wheels are revealed in roadless districts ; the performance is of the class which one expects from military-type rigid six-wheelers.

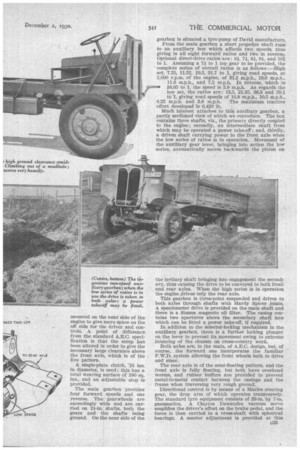

On the morning that we visited the factory at Slough the aid in which the cross-country work was carried out was made more treacherous than usual by a ground frost which had occurred the night before. Over icy grass, including hummocks, rear-wheel drive sufficed to ensure a steady passage for the laden lorry. One of the mud holes was negotiated with rear-wheel drive only, but, of course, with much wheel-spin. When fourwheel drive was inuse the-lorry crawled out of the hole without effort, the lifting effect of the " live " front wheels being very marked.

When driven into lateral hollows considerably deeper than the radius of the wheels the vehicle was brought to rest. It would climb out forwards or backwards without chains ; this was due to the fact that there was no tendency for the wheels to be driven into the opposing bank as would be the case, with a two-wheel-drive machine moving, or attempting to move. forwards.

This new Hardy model possesses many attractions for the overseas buyer who requires one which will tackle with equal success main-road or roadless duty as it becomes necessary.