CARRYING 104 PASSENGI (SEATED) IN A BUS.

Page 54

Page 55

Page 56

Page 57

If you've noticed an error in this article please click here to report it so we can fix it.

THE official opening of the new offices and works of the Associated Equipment Co., Ltd., at ;Southall, Middlesex, will take place in October, the original plan haying been that the plant and machine tools should be transferred there by the end at September net, the desire of the directors and management being that the agents and representatives of• the company, the friends of the directors and shareholders and those most interested in the welfare of the concern should have an opportunity, so soon as the works were fully re-established, of seeing how vastly the manufacturing facilities of the Associated Equipment Co. have been increased and how a model establishment has been created. There will be no departure from the latter part of this plan, even though the work of transfer has been so much expedited that by the middle of May the whole of the plant had been transferred and reerected, and by the middle of July the whole of the administrative staff had taken up their new quarters at Southall ; that is to say, some nionths ahead of schedule,

The gain in time Is not to be ascribed to any miscalculations on the part of the management, but rather to a number of fortuitous circumstances and largely to the enterprise, skill and energy shown by all sections, from the general manager and plant engineer down to the men engaged in the transport.

Mr. George Rushton, the manager of the Associated Equipment Co., was, of course, largely responsible for the scheme of operations, whilst in the carrying out thereof Mr. Jenkins, the plant—engineer, with the staff under him, performed prodigious feats. As many as 50 to 00 machine tools were transferred and put down in their new positions each week, the total number of machine tools to be transferred being 891, weighing in all 3,500 tons, and, in addition to these, there were tools, jigs and gear running into a further few hundred tons.

The whole of the plant was transferred by road, and, by means of powerful nortable cranes, on ,reaching Southall was SO quickly placed in its new position that each machine was again at work with the delay of but a day_ or two. To help forward the output when the demands upon the plant became so great towards the end of the period of transference, some new capstan lathes were purchased. Eighteen of them were ordered on the, Friday, they were brought to London by road during the Saturday and arrived at Southall at 9 o'clock on Sunday morning; by 4 o'clock on Sunday

c32

.afternoon the last of them was in position, its belt was connected up to the overhead line of shafting and they were all at work first thing on Monday morning. •

In the course of our visit we were impressed With the skilfulness of the layout of the plant, a point to which we shall refer later, bar at first we were rather concerned at the small amount of room given to the worker between the machine tools. We found, however, that there was purposa in this, in that lack of space around the machine tools definitely keeps the work on the 'move, and one of the results is instantly obvious in that there is little or no material on the floor.

Of course, the great thing that had to be avoided in the transference of the factory was the disturbance of output, and, as it happened, throughout the whole of the first part of this year the demand for Associated Daimler vehicles (for the products of the Associated Equipment Co. are now marketed by the Associated Daimler Co. under the name of Associated Daimler) has been increasing; so much so, that at the present moment it is two and a half times that of a like period in 1926. This gave great anxiety to the management, but now that the strain is over it is recognized that instead of the output being retarded by the change-over it was definitely improved, owing, no doubt, to the better facilities available at Southall, material having to travel a much shorter course from start to finish than was the case at Walthamstow, so that during the 12 weeks occupied by the transfer the output of completed chassis was 422, and, in addition, a very large quantity of spare parts was manufactured and distributed. Since the end of May the output has been building up until the record figure of 71 chassis turned, out in

one week has been reached, in addition to spares which; constitute the equivalent of a further 29ichassis, so that the 100vehicle mark has been topped.

The addition to the plant to enable this very much .increased output to be obtained from it has not been very large, a few extra machine tools (of which the 18 capstan lathes to which we referred formed part) have been installed, new methods, have been introduced, manufacturing progress has been better co-ordinated and the men have fallen willingly into the new ways of working laid down by the management. A farther factor in securing the increase has been the doubling of the shift. About 40 per cent, of the machine tools are running on the double shift, and it has not been found necessary, so far, to employ a night shift, the only men at work during the night being two who look after the furnaces for the heat treatment.

• It must be remembered that the Associated Equipment factory is not devoted to a mass-production job, making one model only, the manufacture of which is continuous and uninterrupted. No fewer, that nine differ out types of chassis have been made at Southall this year, and of these four are entirely new types, viz., the two chassis for passenger saloons (one with the Daimler engine and the other with the A.E.C. engine), the 3-tonner and the six-wheeler. Hence the orders have to go through in batches of, say, 50 or 100 vehicles of one type at a time; sometimes two types may go through, as, during the course of our visit, we observed two types of engine passing through the engine section.

The layout of the plant is such as to get the very best output in the circumstances, and when a change over from one model to another is made time losses are avoided by skilful planning. The result is that never more than one month elapses between the receipt of raw material and its output in the form of completed and finished chassis ; but, actually, this figure is improved upon in that most of the material emerges from the factory in vehicle form within a fortnight of its entry as raw material.

The main purpose of this article is to deal with the new type of bus which is to be used -for the transport of workers from the east end of London to Southall, but whilst we are considering the new works we may as well complete our survey by remarking that the machine tools are arranged in lines each of which ends at a certain point on the moving platform on which the chassis are erected. In the first bay, for instance. frame brackets pass along a line of machine tools and then reach the frame-erecting section. The frame. when completed, then passes on to the commencement of the moving platform. The next section deals with back axles, the third with front axles and steering, the fourth with gearboxes, the fifth with engines, the sixth with radiators and the seventh with petrol tanks, each completed component reaching the travelling platform at a point which involves the shortest travel.

The offices, by the way, are laid out in a similar manner, so that work flows from one section to another.

The Daily Transport of 1,200 Workers.

To deal now with the chief object of this article, the great task which has arisen in connection with the transfer is due to the fact that so many of the workers, who were originally drawn from Walthatustow, Leytonstone, Stratford and other parts, are desirous of continuing their employment under the company, and, whilst the district in the region of Southall is being developed, there is not the housing accommodation there for them. Therefore, a transport system has had to be laid down in order to bring the workers to Southall. The number of workers at the present moment is 2,232, of whom about 1,200 have to be transported from the east end of London; the remaining 1,000 come from near at hand or from other parts of London, and have made their own arrangements for reaching the works. In order to provide a comfortable means of travelling for those who have to be transported, the company has equipped 24 of the old B-type buses With Cape cart hoods and extra seats (transverse seats replacing the longitudinal seats in the region of the wheel arches), so that each bus will accommodate 40 passengers.

The programme for this transport system is as follows :—The first shift is picked up at 4.45 am., the men gathering at given spots, such as Stratford Broadway or the Walthamstow works and along the route at certain places. Each man is allotted to a particular bus, so that there is no uncertainty whatever about his transport. The journey, according to circumstances, takes from one to one and a half hours. The first shift arrives at the factory at 6 o'clock and is ready to leave at 2 o'clock in the afternoon. The buses return after the first shift has reached Southall and bring in the office staff, which arrives at the works at 8.30 a.m. Six buses are occupied in dealing with the first shift and office staff. Eighteen buses are employed to bring in the ordinary day shift, which works from 8 o'clock until 5.30 p.m. The buses return to the east end and bring back to Southall the second day shift, which arrives at about 1.30 p.m., and they are then available for taking the first shift homeward. One batch of e34

buses takes the office staff home at 5 o'clock, the large convoy leaves at 5.30 p.m. with the day shift, whilst the late shift goes off at 10 o'clock at night. So the transport of the workers is a task for quite a little traffic concern in itself!

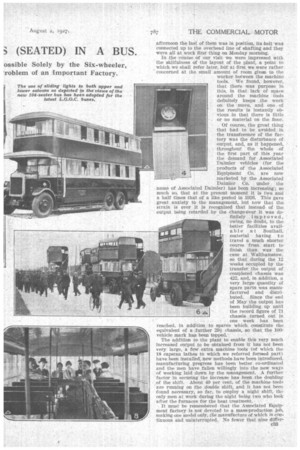

As we have said, the B-type bus seats 40 passengers, and, in putting on the service two of the new sixwheeled vehiclet, the management has in view two objects: (1) to give a thorough test to the chassis under strenuous working conditions, and (2) to secure greater vehicle efficiency in the transport of their workers. To this end the two six-wheeled chassis have been equipped with bodies, each seating 104 passengers; these two buses, therefore, have the largest seating capacity in the world. The buses are being put on different routes each week, and the men are each getting their turn at a ride in them. Being mounted on 36-in. by 8-in. pneumatic tyres, they, of course, give more comfortable riding than the B-type bus can give. One of the buses is equipped with the Daimler six-cylindered sleeve-valve engine and the other with the new A.E.C. six-cylindered poppet-valve engine, thus permitting of a useful comparison between the two types of prime mover.

Features of the Body.

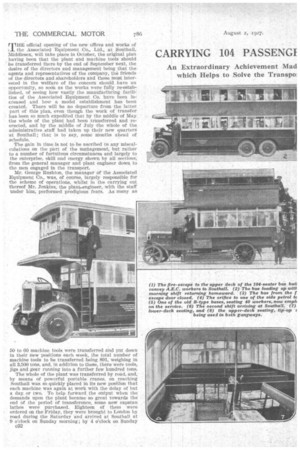

The design of the bus body to seat 104 passengers is extremely interesting, but, of course, it must be remembered that it is devised for a particular class of work, and that it would not be suitable for public service. The seats ere well cushioned and equipped with padded back rail and stretch from side to side of the bus, each row being broken by a hinged seat, which, when tilted over, provides a gangway giving access to the forward seats. The headroom is 5 ft. 8 ins., both on the upper -and lower decks. Obviously, with so many as 55 passengers on the upper deck, it is desirable to keep the centre of gravity as low as possible.

The seating arrangement is carried out in this way :Taking the lower deck first, the first seat backs on to the driver's cab ; this is followed by four rows of seats, each with a tip-up seat, but the first row having its tip-up seat in the centre of the row so as to give access to the inspection door for the gearbox; the tip-up seat in each of the other rows is the second from the left In the region of the wheel arches there are three longitudinal seats, two, as usual, facing inwards, whilst the centre one faces to the left. Behind these are a seat for five (including a tip-up seat) and a seat for four. Thus, the lower deck takes 49 passengers. On the upper deck the first row, again, faces to the rear, and the other ten rows face forward, each having a tip-up seat, the upper deck thus taking 55 passengers and the bus accommodating 104 passengers, each person having a seat.

The height of the lower deck has been reduced by the elimination of the ventilators, but as sliding lights are employed along both sides there is ample ventilation. Giving access to the upper deck is a seven-step staircase taken straight up from the platform and being entirely enclosed. Few people realize how much dirt and dust enter the rear of a bus, drawn in by suction created by forward movement, but one has only to look at the back of a bus with an enclosed staircase to realize the amount of dirt that has been picked up, this, of course, only being a portion of that which has been drawn towards the bus.

A very unusual feature is the fire-escape ladder which has been fitted at the left-band side, a doorway being provided at the extreme forward end of the left-hand side of the upper deck. Whilst such a provision may never be called upon, the precaution, however, is very commendable.

We noticed a new position for the petrol tanks (of which there are two), for, whereas the Public Carriage Department of the Metropolitan Police always calls for the petrol tank to be fitted beside the driver's seat and behind the engine, in this case a tank is fitted at each side strapped to the frame members, the petrol being supplied by an Autovac to the carburetter.

In addition to the eight brakes on the wheels of the

bogie (four operated by pedal and four by hand lever), front-wheel brakes are fitted to the two vehicles, the whole of the brakes being operated through the Westinghouse system.

We were assured by the driver of one of these buses that the steering of the vehicle is as easy as handling a private car, this being largely due to the fact that the worm and worm wheel of the steering gear are very large. We observed, too, that the vehicle was equipped with the 450-watt C.A.1,7 dynamo.

The overall dimensions of the bus are 30 ft. long and 7 ft. 2 ins, wide, the front wheel track being ft. 31 ins., and the rear wheel track 6 ft. 01 ins., whilst the wheelbase is 18 ft. 6 ins.

These two buses are, of course, not run as hackney vehicles, but, as they are largely under test and the workers ard not asked to pay for the journeys which they may take in them, they run under trade identification licences.

To Mr. George Rushton, manager of the Associated Equipment Co., Ltd., a member of the Institution of Automobile Engineers and an associate member of the Institute of Transport, is due much of the credit for the layout of the new works, for the management of the whole of the transfer and for the present organization. He has made a special study of works management and had paid visits to the Tjuited States for that purpose. His early training was in the works of -a mining machinery manufacturer. He joined the London Road Car Co. in May, 1908, and went over to The London General Omnibus Co. on .amalgamation. There he has worked up through various departments; reaching the .position of production engineer at the ChisWick overall factory, and finally the management thereof. After his return from America, where he spent the concluding three months of last year, he was invited to take over the joint nianagement (the, works department) of the Associated Equipment, Co., Ltd. Thus, the new works constitute a monument to his skill and capacity.. Lord Ashfield has, so recently as Thursday last, expressed in a circular letter, -addressed to ever member of the staff, the appreciation of the board of directors of the way in which the transfer to Southall was carried out, of the ,progress which has there been made since its opening and of the better all-round work Which is being done in the factory.