,HINTS ON MAINTENANCE.

Page 32

Page 33

If you've noticed an error in this article please click here to report it so we can fix it.

How to Get the Best Out of a Vehicle, to

Secure Reliability and to Avoid Troubles,

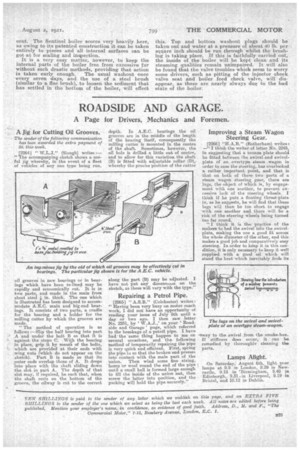

CONTRIBUTIONS are invited for this page from fleet managers, drivers, garage foremee and mechanics, works staff and draughtsmen, and ' will be paid for on a generous scale. Every system, make, and type of commercial motor vehicle will he dealt with, and the matter should be written with a view to the disclosure of workshop and garage practice in the maintenance of a vehicle—practices which, whilst they may be quite normal, are peculiar to the particular vehicle and may not be generally known to those responsible for its running. Expedients and suggestions for overcoming roadside and other troubles are covered in the following page, headed. Roadside Roadside and Garage." Communications should be addressed to "The Editor, The Corn, meroial Motor, 7-13, Rosebery Avenue, London, E.C. 1."

58.— End Play in Leyland Steering.

The usual method of taking up the end play in the steering box of a Leyjand vehicle is by inserting a -washer, of a thickness varying with, the amount of end play, behind the flange of the bush in the plate on the side of the steering box. This plate can he removed by unscrewing the seven g in. nuts without dismantling any other part, of the steering, but it will sometimes be found difficult, with the ordinary tools, to remove the bush without damage, and the sketch which we. reproduce shows a useful little device that can be. used for extracting the, bush without daina,ging it.

The tool consists of a piece of flat. steel " 11," shaped as shown, with the ends bent out to project under the bottom of the bush. " C)" is a distance piece with a slot cut in it to allow for fitting over the centre' screw. After the ends of " B " are sprung . under the bush, the,insertion of " C" prevents them slipping out.

" is a piece of metal smaller than the diameter of the bush and provided to spread the pressure of the bolt over a larger surface. A convenient size for the centre screw is in. Whitworth.

59.-011 Consumption on Thornycrotts.

Experience in:running a fleet of J-type Thornycroft lorries working in London and the Home Counties showed that the oil consumption on the partieular ve.hiclea-comprising this fleet was excessive. Many experiments were carried out to reduce it, but with out satisfactory results. That the engines .were getting too much oil was shown by the fact that they were emitting clouds of smoke from ill, evemistat moderate speeds.

Consequently an appeal was made to the makers, who provided a set of specially made baffle plates and special studs for fixing them. To make the addition it was only necessary to lower the bottom half of e36 each crankcase a;nd fit the battle plates from underneath the engine. Also four of the e-iiinder holdingdown studs were removed and the, special ones substituted.

The baffle plates consist of four separate pieces looked by four nuts, and the use of these plates in this particular instance caused a remarkable reduction in the oil consumption,. whilst at the same time there were no signs of under lubrication.

60.--An Omission,

D. Napier. and Son, Ltd., have drawn our attention to the fact that in Hint No. 43 there is: rather an important omission, i.e., it should have been stated that before the adjustment can be made the nuts holding the magneto bracket and. Water pump in pmition must be slacked off so as to permit the whole housing to Move in the slotted holes previded for this purpose. The makers have known instances where the bracket has been broken off as .a, result. of attempts to tighten the ehain without first proceeding as mentioned above.

61.—Assembling Daimler Engines.

In the ease of a Daimler engine it is sometimes difficult to enter the piston with its. rings into the inner' sleeve. The rings are pinned and of course, a slight turn of the sleeve causes one or other of the rings to spring out over the top of the stopeain, A method which can be adopted. to obviate this trouble and to prevent breakage of the delicate piston rings., is to tap out the gudgeon pin from the piston and connecting rod, .plaee the. inner sleeve upside down on a bench andensert the piston as far down as the gudgeon pin hole.. Then reverse the piston and sleeve and tap the gudgeon pin home. The job can now be completed by refitting the large gii.dgeon pin holding ring, which is a.'-simple matter as this ring

is not pinned, it is essential square up the piston and sleeve with the base before assembling.

62.—Economizing Fuel on Sentinels.

The question of economy in fuel consumption is largely dependent upon the state of the engine boiler and the care with which this is looked after. It is essential that the boiler be washed out at stated periods: preferably this should take place once a week. The steam vehicle, which of necessity must pick up water where it finds it, cannot always choose

as to the purity. The mineral salts contained in different waters vary greatly, and these give rise to what is generally called hardness. In the boiler these salts are precipitated out of solution and settle an the tubes and inside of the plates, thus forming a crust or fur, which becomes, if neglected, extremely hard and. difficult to remove. Further, this crust is a very bad conductor oVheat, and when it reaches more than I's in. in thickness it is impossible to maintain steam in a proper manner, without increasing the fuel consumption by about 15 per

cent. The Sentinel boiler scores very heavily here, as owing to its patented construction it can be taken entirely to pieces and all internal surfaces can be got at for scaling and inspection.

It is a very easy matter, however, to keep the internal parts of the boiler free from excessive fur without such drastic methods' providing that action is taken early enough. The usual washout once every seven days, and the use of a steel brush (similar to a flue brush), to loosen the sediment that has settled in the bottom of the boiler, will effect this. Top and bottom washout plugs should be taken out and water at a pressure of about 40 lb. per square inch should be ruu through whilst the brushing is taking place. If this is faithfully carried out, the inside of the boiler will be kept clean and its steaming qualities remain unimpaired. It will also be found that the valve troubles which seem to worry some drivers, such as pitting of the injector check valve seat and boiler feed check valve, will disappear, as these are nearly always due to the bad state of the boiler.